Results 11 to 20 of 26

Thread: An explanation, please!

-

08-01-2017, 09:53 PM #11

I have used the Glass Barber Hone with assorted super fine grits. It works if all stages earlier were done well. It will not make a poorly set edge better. It can tune up a good edge with a polishing agent applied.

Pasted strop better for most usage!

YMMV

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

Steel (08-01-2017)

-

08-01-2017, 09:57 PM #12

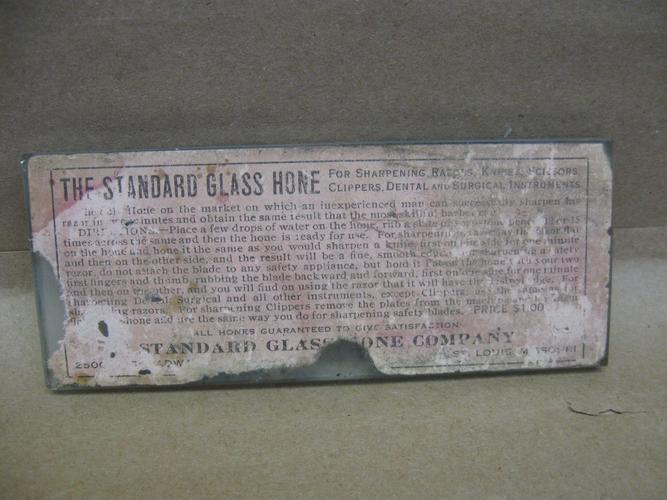

I believe Victory Hone Co. out of Des Moines made small glass hones. fond of those little guys because they wrote "don't blame the hone" right on them! that said, i'm sure when people say "finish on glass" they're referring to Shapton Glass 99.99% of the time

-

08-01-2017, 10:12 PM #13illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

A few clarifications here…

A glass plate for honing is piece of glass, often float glass, that is flat and smooth. By itself it does not cut steel, so you have to add a grit slurry onto it to do any honing on it.

Shapton GlassStones are not the same as glass plates. You do not hone on the glass. You hone on the opposite side and the glass is just a support material.

The Shapton 30k GlassStone has 0.5 micron grit in it.

The Suehiro Gokumyo 20k has 0.5 micron grit in it.

-

The Following User Says Thank You to Utopian For This Useful Post:

Geezer (08-01-2017)

-

08-01-2017, 10:18 PM #14Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

As is, I agree with Richard. It's fun to play with and can be a good finisher. I think if it were about 2 inches longer there really wouldn't be much the little fella couldn't accomplish. As it is, the dimensions make it hard to keep a slurry atop the hone. I used my Dragon's Tongue to build up a slurry on it, so that's only going to get the blade in the 6K ball park. But a few strokes on just wet glass brought it up over 8K, and the blade is still shaving well enough that I haven't felt the need or want to change anything. It's a fun toy to keep around, but I don't know how much actual use I'll get from it.

-

08-01-2017, 10:28 PM #15

Aloha!

This whole thread reminds me of my old Amateur Radio days grinding crystals to frequency on a glass hone.

This was a very scientific process.... not.

You basically put some Ajax and water on the glass hone, then circled the crystal (basically a shaved sliver cut crystal) slowly and methodically for a while. Then you washed it off, dried it out, and tested the frequency. You did this until you got close to your frequency and then removed the Ajax to finish the honing (grinding) of the crystal with just water to "fine-tune" it.

I'd forgotten about glass hones and grinding crystals until this thread.

Thanks for the memories, gents.

-ZipLast edited by ZipZop; 08-02-2017 at 12:06 PM.

"I get some lather and lather-up, then I get my razor and shave! Zip Zop, see that? My face Is ripped to shreads!"

-

-

08-01-2017, 10:38 PM #16illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

I had heard of crystal radios but had absolutely no idea that was how it was done!

-

08-01-2017, 10:58 PM #17

A crystal for the old cat's whisker raw galena crystal radios was a different item, the sweet spot on the crystal was tapped by the cat's whisker for an electrical diode to reduce the frequency of an incoming signal. In those days the closest station to the receiver.

More photos:

Crystal sets

Here the crystal is lapped to become a flat plate, between contact plates, which vibrates at a constant frequency to assure the tuning of a radio transmitter or receiver stays within specified frequency assigned by the governing body of radio frequencies in an over crowded radio frequency spectrum.

Crystal_oscillatorBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

Utopian (08-01-2017)

-

08-03-2017, 06:09 AM #18Member

- Join Date

- Mar 2016

- Location

- indiana

- Posts

- 54

Thanked: 9

Wait a minute, Shapton hones are actually glass? What kind of glass? Tempered I believe from the picture I saw of a dropped one. Seems to break into smaller chips instead of shards. Does this mean I can get a piece of thick glass, rough it up to 20k and it will actually be useful as a hone? I'm a tool maker by trade and my DIY buttons are being pushed. Lapping glass down to 20k, or what ever sound easier than lapping my Arkies up to.... well anything.

-

08-03-2017, 08:29 AM #19

It's possible due to the abrasive.

Alu oxide is very stable, and has a very high melt point. So you can mix it in with a wide variety of materials even glass. And it's not going to have it's properties as an abrasive altered.

The type of glass they use, I have no idea. There are hundreds of grades, and even some of the harder glass grades fall under the melting point of alu-oxide. The point been the glass must be softer that the steel so it has no effect in honing. There is a balance that needs to be made. If the glass is too hard then it will not yield and give up new abrasive, too soft it will wear too fast.

In reality it's better to think of glass hones as fully vitrified. As opposed to ceramics that are baked and semi-vitrified.

A glass plate is not a hone, It is not hard enough to abrade steel by itself. You can add an abrasive, Powder, paste,film, but the glass itself is just providing a flat surface.

A naked glass block can be used to remove swarf from a hone. The naniwa superstones are know for loading in this manner and I have a little optical glass block that I use to remove the swarf. It's fast, and doesn't leave any grit on the hone that can alter the abrasiveness of the hone.Last edited by Iceni; 08-03-2017 at 08:53 AM.

Real name, Blake

-

08-03-2017, 11:40 AM #20Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Not quite. Shapton Glass stones are an abrasive on a glass backer. The glass barber hone requires a buffing media like Iceni said. Slate, soap stone, pencil, some sort of abrasive paste or powder to do the sharpening. The glass just provides a hard flat surface to contain the slurry.

-

The Following User Says Thank You to Marshal For This Useful Post:

Geezer (08-03-2017)

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote