Results 1 to 10 of 12

-

07-09-2019, 11:13 PM #1Member

- Join Date

- Jul 2016

- Posts

- 36

Thanked: 2 how do you deal with not-so straight edges?

how do you deal with not-so straight edges?

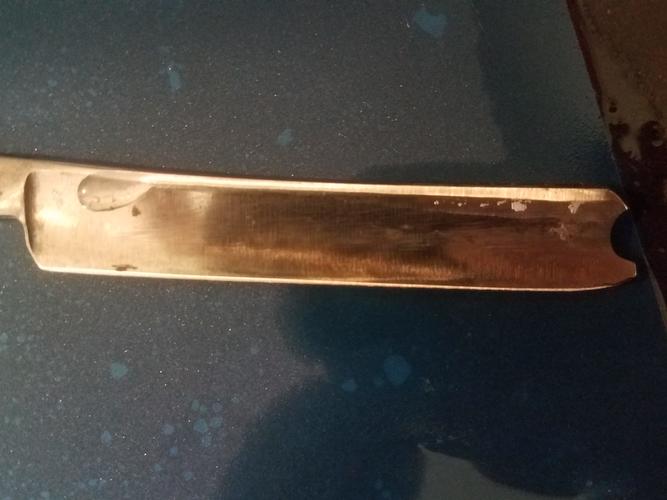

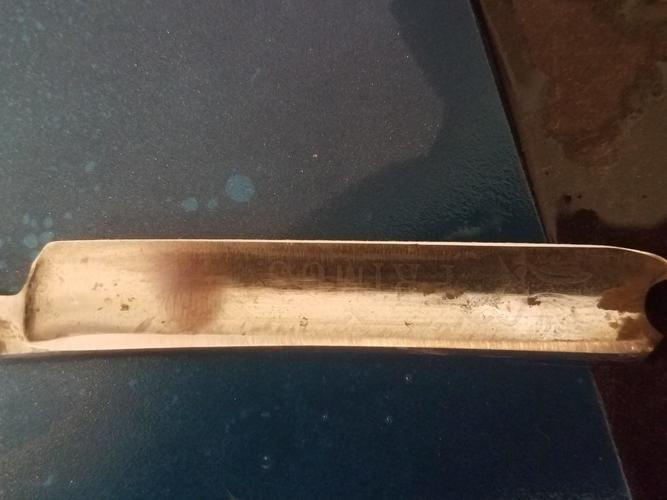

ive got two razors, both with edges(blade edges) that are not so straight. i just got me some lapping film the other day to learn on. i lap on a finish ground steel plate. the one razor is a cheap o that i dont really care about, never had it shaving all that well. ran through my films, and i t shaved better than the one i do care about(so now im working on that one). the one that is my "learning blade" is a crown 6/8(ish) and the other is an ern 4/8(ish). the crown on one side has a wider "bevel" in the middle, despite my using pressure at the heel and toe of the spine. im having similar isues with the ern. the edge on the ern is also MUCH smaller than the crown. is this due to the skinnier blade? is it that important to have the edges be even? the crown shaves really pretty well with the slight eneveness in the edge. how do you go a bout tacling these issues?

I hope my Photos are clear enough. i do not have a loupe, yet. one is on its way

-

07-09-2019, 11:47 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,389

Thanked: 4821

When you are learning to hone, tape is a great way to protect the spine from too much pressure on the spine.

Gssixgun has some great videos on YouTube. There is a series of three on honing a smiling wedge that shows great strokes for blades with curved spines and smiling no edges. As the smile is desirable, adjusting your stroke to maintain it is important.It's not what you know, it's who you take fishing!

-

07-10-2019, 12:08 AM #3Member

- Join Date

- Jul 2016

- Posts

- 36

Thanked: 2

You know, I thought about "breadknifing" although I had never heard or seen anyone do it. I almost thought about asking about it(didn't know it was actual "practice") I don't know if you can see, but on one side of the ern, it looks like there's more wear on the heel edge of the spine on one side, that was there before I started. I couldn't find my electrical tape, I tried masking tape, but, I'm sure as others have found out, it doesn't really work.

Glenn is good people. I think he repinned and worked on the crown(i had it and another razor when I sent him a razor. I can't remember if I sent him both, or just one)I'll watch those videos, and go back to the practice blade to see how it helpsLast edited by Nhyrum; 07-10-2019 at 02:44 PM.

-

07-10-2019, 04:49 PM #4Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,091

Thanked: 292

Any time you are honing a razor for the first time, I recommending checking to see if the blade is warped. Even the best blades often have a little warp, but some blades are warped to the point they require special attention when honing. Dr. Matt as a video demonstrating how to do a tap and wobble test to check for warping. Check it out.

-

07-10-2019, 08:25 PM #5Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

You're probably going to struggle with that 4/8 blade. I've got a few that are worn down to that point and whether it's from years of wear, or me nibbling out a big nick from the edge, mind have issues that simply don't exist with other blades.

Bevel thickness doesn't matter, what does matter is that they meet completely from heel to toe. You do want the edge to match the curvature of the spine - for the most part. I have an old Sheefield that sort of curves in at the toe as opposed to following the spine. This is a desirable trait so I let that be.

The best fix is learning a good 'rolling X' stroke. I've yet to meet the blade I couldn't successfully hone with that technique.

The other thing to keep in mind with the smaller blade is your technique may be off. With a 6/8 you want to keep the blade 1-2 spine widths away from your cheek. With a thinner blade and doing precisely that it always tugged and pulled in spite of me being unable to find anything wrong under a loupe. One day I tried the blade, shut my brain off and just let muscle memory take over. I found the blade shaved beautifully. I was just holding it at too steep an angle. Scraping rather than shaving, so to speak.

-

07-10-2019, 08:28 PM #6

A smile is a good thing IMO, and a smiling blade can not pass a tap and wobble. So there's that.

-

The Following User Says Thank You to bluesman7 For This Useful Post:

sharptonn (07-24-2019)

-

07-10-2019, 10:36 PM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, first, get all that rust off of both blades. Scrap it off with a single edge razor blade, then polish with 000 steel wool and WD40. If not, the rust will imbed in your strop and it will scratch the bevel and chip the edge. Rust is very abrasive. Once in a strop, you may never get it all out.

Second do not lap on steel, pick up a glass tile, a 3x12 inch glass tile sells for 3-5 dollars and can be lapped flat easily with a sheet of 220. Once lapped flat it will hold lapping film very well.

A 1k stone will make your life so much easier, you will need to do some edge correction to both razors if you want to make them optimal. You can buy a good King 1k for $20. You can make the jump from 1k to 1um easily.

The Ern needs the heel correction badly. You are honing on the stabilizer and keeping the heel off the stone. This is an advanced honing technique and may not be for you. All the massive spine wear is probably accountable to the mis- shaped heel and riding on the stabilizer. Past honers have tried to force the heel on the stone and needlessly ground the spine with excess pressure.

Electrical tape and heel correction would have prevented all that damage, it will still prevent further damage to the spine.

Third both razors would benefit from a slight smile matching the spine, probably had one originally and can easily be re-profiled to a smiling edge, but this also is an advanced procedure and you will need a low grit aggressive stone, preferably a diamond plate or diamond file.

Once reprofiled, a rolling X stroke will hone them just fine. Here is a post on heel correction, (How to Correct a Heel) and another on reprofiling a smiling blade, (Make me Smile)

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

FatboySlim (07-12-2019), ScoutHikerDad (07-22-2019)

-

07-22-2019, 11:05 PM #8Member

- Join Date

- Jul 2016

- Posts

- 36

Thanked: 2

ill do that. ive checked out those two posts and they both seem relatively simple.

I do not see an issue using my lapped steel plate. i spent some time with a coarse diamond stone on it getting it really nice and flat. but, i do know im a beginner, so i know far from everything. i do plan on picking up a glass tile soon.

-

07-23-2019, 01:55 AM #9Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You can hone with film on anything flat, but glass is easily flattened and once flat it will hold film very well. It will look like a fine frosted glass finish that holds water well and the film sticks to it. Once it is stuck to a glass tile, you can do anything you can do on a stone.

Plus, with 2-3 plates, you can have multiple plates with different grits on them and move from one to another if you are honing a lot of razors.

Film can give you a smoking edge, but in the long run, if you hone a lot a stone is less expensive and a little less hassle. I still set a bevel on stone and go to a 4 and 8k then finish on film. You can tailor an edge with film, and it can be a plus on some chippy, very hard new razors, like Harts.

-

07-24-2019, 12:20 AM #10

Unfortunately , looks like someone has tried to make them straight & created a bunch of spine wear.

A razor's edge should follow the curvature of the spine.

If you try to hone straight up & down on a 3" razor same as you would a 2" kamisori, you will hone to a frown with all sorts of ugly wear.

As for warped blades , learn how to rock n roll your X-strokes & most warps or geometry issues become irrelevant.“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote