Results 3,341 to 3,350 of 3708

Thread: Hone of the Day

-

06-02-2020, 04:14 PM #3341Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

"Here's what could have affected things: I did some laps on a Seuhiro Gokumyo 15k before moving to the Ark and Escher.”

I do not think it does anything for the edge, except to provide a clean base line for the finisher, no deep stria from previous grits. If anything, you are going backwards in grit, but grit size does not always equate to performance. It is a new edge, whatever the final finisher is.

I use an 8k Naniwia Snow White, pre-finisher, that leaves a near mirror finish, prior going to any finisher. This leaves a clean stria free bevel and straight edge, so all that is left is just the finish stone bevel and edge. So, if there is an issue it is the steel, finisher, or the finisher… me.

I too have found Thurigian edges not as keen as other finisher but work well with Sheffield steel. Arks and Jnats for me provide the keenest and smoothing shaving edge, sharp is easy.

-

06-02-2020, 05:04 PM #3342

Food for thought, my edges off thuri's got better going from 8k rather than 12k. Look the same under high magnification, but feel worlds apart.

Going from 12k to a thuri just seemed so harsh and the cutting ability was similar.

-

06-02-2020, 05:26 PM #3343Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,389

Thanked: 4821

My theory is the higher grit we go, the thinner the fin gets. The thinner the fin gets, the weaker it is. So to avoid that it either needs less work or be fatter. To make it fatter, we need to change the angle. I’m not into complicated math, so I go the more simple route. It’s all theory and supposition though. I could be talking gibberish. I do have some razors with many shaves on them. I do not keep records though amd rely on me,pry, so it really is just theory.

It's not what you know, it's who you take fishing!

-

06-02-2020, 05:42 PM #3344

Well, as Euclid mentioned I also have a Snow White. I'm tempted to do a few with just 8k Snow White to Escher/Thuri.

-

06-02-2020, 05:45 PM #3345

-

06-02-2020, 08:36 PM #3346

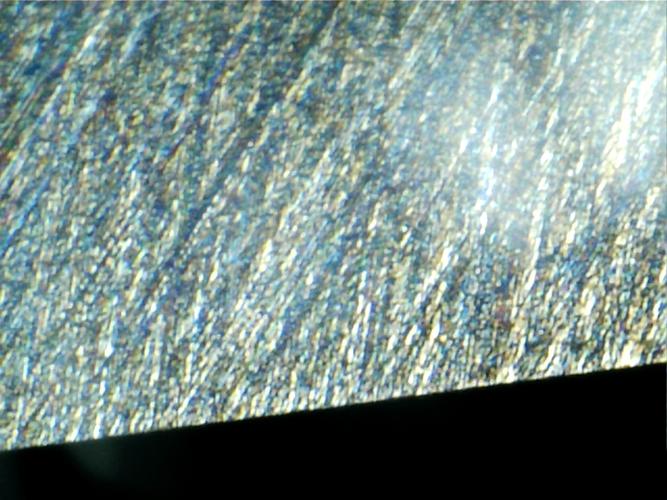

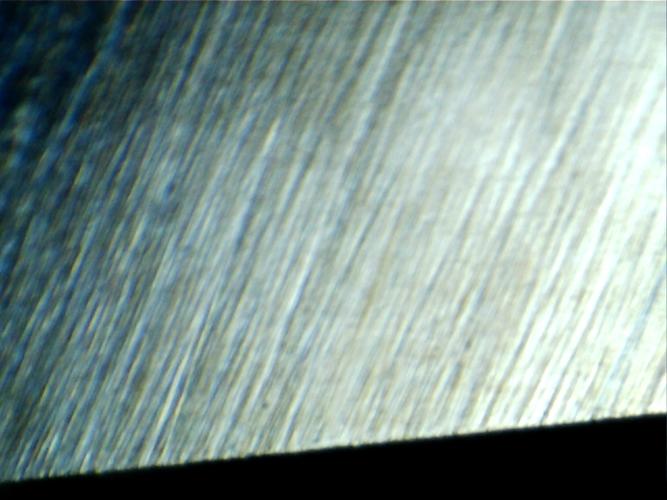

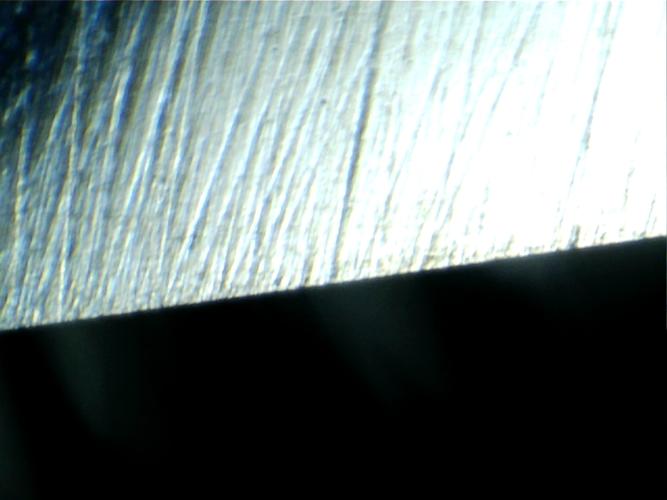

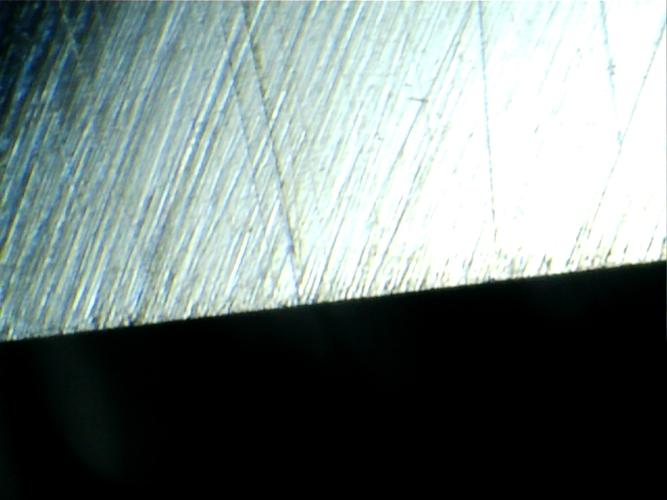

Had this on the grinder today then on the stones for an Escher finish.. It has a very smooth HHT .. I cant wait to test it. Thanks

Sheffield Steel.

1K Debado . Shallow scratch marks, amazing feedback on this.

5K Naniwa . The corner fell off today, woops, i'll glue it back on.

10K Great stone but every stone is great.

Yellow Green

-

06-02-2020, 09:54 PM #3347Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“My theory is the higher grit we go, the thinner the fin gets. The thinner the fin gets, the weaker it is. So to avoid that it either needs less work or be fatter. To make it fatter, we need to change the angle.”

I absolutely believe this, and proved it to a point. Years ago, I got deep into micro paste and made tons of pasted strops with all kinds of paste especially CBN and Diamonds.

The bevels were stria free, super straight edges and shaved like a laser, but did not last. The edges were too thin and micro chipped. I was doing 50 -200 laps on .50 CBN and finish on .125 & .10.um (.125um is 120,000 grit and .10 is 160,000 grit.)

So, it is very possible that doing more laps at 12k, looking for a perfect bevel is thinning a bevel and edge too much.

The easy fix is, Joint the edge, one lap on the stone’s corner and re-set the edge in 10-15 laps. I joint the edge even on Jnat or Ark finisher, the higher the finish the easier it is to re-set the edge. Arks may take a bit more. I try to do as few laps as possible on the reset for a stronger edge.

So, if you go too far Joint it. Also try 2-3 final edge trailing no pressure strokes and micro bevels are options.

-

06-02-2020, 10:20 PM #3348Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

“Well, as Euclid mentioned I also have a Snow White. I'm tempted to do a few with just 8k Snow White to Escher/Thuri.”

I also saw the same issue, when pre finishing up to the 20k SG, then naturals. I started to back down the progression, in pre-finish, until I got an edge that was easy to final finish on a natural but, would leave a stronger longer lasting edge. For me that is the 8k.

When you go to 8k, try to do as few laps as possible to remove the previous stria only at the edge. Once the stria clears up about a 1/3 of the bevel from the edge, it is done. No need to remove all the stria on the whole bevel, just clean up the edge. This will make a stronger thicker and straighter edge, we are talking microns here.

A lot depends on the steel.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

sonnythehooligan (06-02-2020)

-

06-02-2020, 11:24 PM #3349

Hard kiita that I initially tried with an asagi tomo. Results were so so. I went back to koma and then as a tomo I used the piece that broke off. Finished on slurry without much dilution, kept it nice and hydrated though. Silent HHT and man, wiped whiskers off and absolute comfort.

Which actually pissed me off that it broke during shipping. It's an old stone, it has the hand saw marks and it really made me sad it was damaged.

-

06-03-2020, 02:30 AM #3350

That, would suck.! But looks to have some decent realestate, yet. About the same as a Escher, barbers delight.

Mike

23368Likes

23368Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote