Results 21 to 27 of 27

Thread: Using a pen as a sharpness guide

-

05-12-2017, 03:58 AM #21

i don't get it, if it was shave ready why was you going straight to the hones before you even know how to shave? learn to shave and strop, until then you don't even have a clue if its shave ready. do yourself a favor and slow down, and learn the process. not to mention honing a straight razor takes some experience, its not like a knife where any body can sharpen one. Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

The Following User Says Thank You to tcrideshd For This Useful Post:

Beemer (05-12-2017)

-

05-12-2017, 03:42 PM #22Junior Member

- Join Date

- May 2017

- Posts

- 13

Thanked: 0

TC,

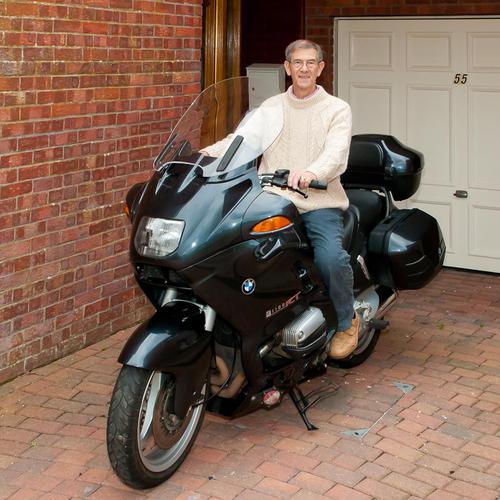

It was Thiers-Issard that stated it was shave ready and I did have several shaves before the Norton arrived in the mail. You are quite right that I have little patience. I'm like that with a lot of tasks that involve new skills. Last year I bought a new very expensive piano and learned to tune it myself. This was despite several professional tuners telling me that I should not attempt it. Another impulse was to take a four day motorcycle course, pass the test, on a bitter February 2000 day take a 200 mile train ride to buy what you see in the photo and ride it home and then for 12 years.

So here I am with a $350 razor (£250 uk) and risking ruining it, but maybe not 😉

Ian

-

05-12-2017, 04:19 PM #23Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

As said, the marker ink test is not a test of sharpness, or that the bevels are meeting. It will only tell you, if you are honing to the edge.

If you take your photo and open in a photo editor and magnify 200x you will see, the edge is fuzzy and likely, not meeting. You can see it in your pic, if you know what to look for.

So, a couple thing first, what are you stropping on?

Did you lap the Norton’s flat? What with?

Which brand of Chrome Oxide are you using and what is it pasted on? Not all “Chrome Oxide” is pure or razor quality. If it is not pure, it will leave an edge exactly like you have.

What are you taking your bevel pics with? Nice pic, by the way, and nice even stria pattern.

You can get nice shaving edge with a Norton 8k and Chrome Oxide, but it will take some work and you will need to master or at least learn to strop better. A razor edge is very thin and fragile, we cannot see it until at lease 1000X.

Stropping while not really that difficult, most folks, over think it, it can take some time to master.

Look at the Toxic sharpening video and make sure the bevels are meeting fully as show in the video, then strop on Chrome Oxide using light pressure, keep the spine on the strop, stop and flip… and go slow, with little pressure.

A single swipe on a strop can easily ruin a razor edge.

And tape the spine, to protect it until you learn to hone. New honers often cause irreparable damage to the spine, tape at the least will prevent that.

In your case, you are probably very close, a single layer of tape and 10-15 laps will probably get your bevels meeting.

-

05-12-2017, 05:07 PM #24Junior Member

- Join Date

- May 2017

- Posts

- 13

Thanked: 0

Hi Euclid440,

Interesting forum name so I'll take a guess. I live in Scotland a few miles where Euclid monster machines were built. See Explore The History Of Terex Trucks

Re your questions:

Strop is a USA made "Mountain Mike" 3" hanging double leather/linen

Paste is by Dovo Germany

Norton is flattened using pencil lattice and wetted 400grit silicon dioxide paper mounted on plate glass.

x200 photo taken using Veho digital microscope with led illumination (bad for reflections)

This razor came with significant honing marks on the spine so using tape seemed unnecessary. I do not think that Thiers-Issard France tape when factory honing.

I'm going to spend time looking at the edge as it faces me using a bright light and loupe as I have been advised. Thanks for your reply,

Ian

-

05-12-2017, 08:23 PM #25Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Sounds like you are properly geared up.

While the tape will protect the spine from scratches and wear, for new honers it is recommended, because… as a new honer you will, typically, do way more laps and use more pressure, than needed, until you figure out honing.

Once you remove metal from the spine, you can never put it back. A simple piece of tape will prevent that and at least the edge geometry will remain the same.

Then once you master honing, and are able to produce a shaveable edge in a few light strokes, wear is not an issue.

That and as I said earlier, you are probably very close to a shaving edge, a single layer of tape and 10 or so light laps on a freshly lapped 8k hone will bring the bevels together nicely and some Chrome Oxide will smooth out the edge.

I am not sure about Dovo green paste so for now leave it out of the equation. Some “Green Paste” contains other abrasives, which is why they call it Green Paste and not Chromium Oxide.

Tape and hone on the 8k. Look at the edge before and after the 8k, strop on linen15-20 laps and leather 15-20 laps and look at the edge again. That should get you there.

Then try the Green Paste, look at the edge and see if it I improved.

The Mountain Man strop is a nice strop.

You may want to invest in a diamond plate in the 300-400 grit range for lapping and resurfacing the stone face. I give my stones a quick lap before use, and before I lay my final finish laps. Just a few quick swipes.

Make sure the edges of the stone are chamfered and the final laps are done parallel to the edge and or rounded. A ragged corner of a stone, will destroy an edge and cause you fits, till you figure it out.

You can do it with Wet & Dry but a diamond plate is quicker and easier, DMT, Easy Lap, Chef Knifes to Go or Atoma, they all work. And run from 30 to 80 dollars here in the US.

Here is a good thread where a new honer takes an edge from Ebay beater to shave ready, post 42, page 9, Photos 4 & 5 (upper right hand corner) show and edge that is close, (not fully set). Post 51, page 11, first photo, shows a fully set bevel, as demonstrated in the Toxic video.

Good photos of what to look for.

Second Try at Honing.

-

05-12-2017, 08:36 PM #26At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,026

- Blog Entries

- 1

Thanked: 13245

Dovo pastes

"Green Sharpening Paste is the coarsest with a particle size

averaging 5-8 microns and should be used on a very dull edge.

Red Sharpening Paste is less coarse with a particle size of 2-4

microns and will refresh a mildly dull edge.

Black Sharpening paste is the most fine at around 1 -2 microns

Yellow Paste has no sharpening qualities and is used as a leather

strop conditioner on your "everyday use" strop.

White Paste is used as an edge polish on the LINEN STROP ONLY!"

Keeping in mind that the Dovo pastes are actually rather soft/mild cutters so the micron sizes are only part of the equation

-

05-12-2017, 09:21 PM #27Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Interesting. I didn't realize Dovo pastes had material that coarse in them. Still sounds like green wouldn't be an improvement over 8k and red would be a side grade, or very slight upgrade.

Then again, I imagine it would sink a bit into a fabric strop so depending on the material it's strewn across results may vary.

Meh, I'll stick with Chrome Oxide, CBN, and FeOx and be happy.

27Likes

27Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote