Results 21 to 30 of 35

Thread: My bevel angle calculations

-

07-08-2009, 09:59 PM #21

Well the formulas (either mine or Ben's) work for only a section of the blade. So you could measure the thickness of the spine and the distance from the spine to the edge at different points along the edge and get different angles. For non-straight razors (i.e. the edge isn't straight), it would come to no suprise to me that the angle changes somewhat as you progress from the heel to the toe. The angle doesn't have to be constant throughout the edge. I think only a perfectly straight edge with a perfectly uniform wear on the edge and the spine will produce the exact same bevel angle throughout the edge.

Well...I guess you could have a smiling razor that had the same angle throughout given that the distance between the edge and the spine was constant throughout the entire length of the razor (i.e. they both have the exact same curvature), as well as having perfectly even wear on the edge and the spine.

-

07-08-2009, 10:06 PM #22

Thanks Dave that makes sense.

But you know; what I meant was, how does one get that bored?

-

07-08-2009, 10:07 PM #23

It depends. If the width of the razor (from spine to edge) varies proportionally to the spine thickness, then nothing. The formula stays the same.

If the razor width remains the same but the spine thickness varies down the length of the razor, then you can take several measurements, apply the formula for each set of measurements, then interpolate the data for 'close enough' measurements.

Otherwise (if you want just one equation), you can set up an integral (calculus II techniques). But, since the variation in thickness is probably pretty constant per unit of length, I'd just take several measurements and then plug the numbers in the formula.

-

07-08-2009, 10:15 PM #24

I have a math degree, so what entertains me might be different than most people.

It would be AWESOME if you could use calculus in calculating the angles. Would the resulting answer not be a value but a function dependent on one variable, how far along the razor you'd like to know the angle of? That would be cool.

-

07-08-2009, 11:10 PM #25

not at all

just didn't understand the equation (of course I didn't really look, like it would matter anyway)

and I wasn't trying to say anything about the PT applying here but rather to give an example of my non-use of formulas

as I explained to my high school math teacher when he flunked me for not showing my work (the work he wanted to see done HIS way)

"The idea behind swinging a hammer is to sink a nail, not to exercise my damn arm!!"

I hope all this work turns into something (like an online calculator LOL)

-

07-09-2009, 12:04 AM #26

-

07-09-2009, 05:28 AM #27Retired Developer

- Join Date

- Mar 2008

- Location

- Berlin

- Posts

- 3,490

Thanked: 1903

Oh, lovely. I have always hated maths. Would you kindly help a heathen find the flaw in the following?

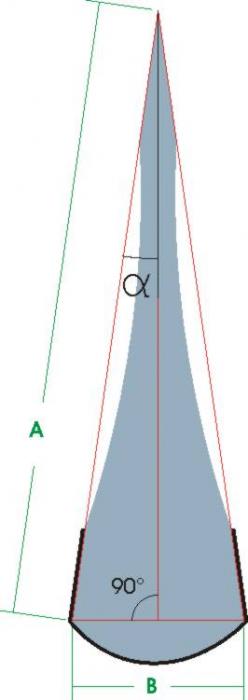

The picture below is supposed to show the the profile of a razor. The red line shows the triangular geometry of the razor and the enclosed bevel angle. The razor is divided in 2 identical rectangular triangles.

Calculating the acute angle for any given rectangular triangle - as far as I remember and understand it - is: Sin a = The half of B divided by A. We would be using the half of B, and we're only calculating half of the razor's bevel angle. However, we're not looking for Sin a, but a itself:a = arcsin ((B/2)/A). And apparently, that's only half of the razor's bevel angle. That's why in the spreadsheet the complete angle = 2*(arcsin ((B/2)/A).

Now, when we tape the spine as shown by the black line in the drawing, and we assume that the thickness of typical electrical insulation tape is 0.15mm (keeping in mind that one layer thickens the spine twice, i.e. once on each side, as shown in the image), we will end up with a "measured spine after taping" which will be 2*0.15=0.3mm thicker than before. This brings the formula to: 2*(arcsin ((B+(2*tape_tickness)/2)/A).

Right?

By the way, I should think that if you need to know the exact thickness of your tape, stick 10 layers together, measure them and divide by 10 (this also divides the inaccuracy of the measurement by 10).

That would be most cool.

Thanks!

RobinLast edited by BeBerlin; 07-09-2009 at 05:30 AM.

-

07-09-2009, 05:48 AM #28

The first equation is correct, but there is a small flaw in the second equation. You are correct in saying the width of the spine changes giving you the extra term to be added to B, but it shouldn't be 2*tape_thickness since you are only considering half the angle in this triangle, thus only 1*tape_thickness, the thickness of the other half of the tape is already accounted for in the 2* in the beginning of the equation before the arcsin term. Also, A in the second equation is not the same A as in the first one. When you add tape, you are not only increasing the thickness of the spine, but also the distance (the hypotenuse "A") from the edge of the bevel to the spine.

So you could the formula: 2*(arcsin ((B+tape_tickness/2)/A), but the A in this formula would have to be the measured distance from the spine w/tape to the bevel. Note that I took out the 2* coefficient in front of the tape_thickness variable.

If you look at some of the previous posts between Ben and I, we were discussing this problem. But, it was then accounted for.

I hope what I wrote makes sense. I can always write up what I mean by hand and scan it if I need to be more clear. It's almost 2 AM, so it may not be the clearest.

P.S. I like to write the symbol for inverse sin and tan, basically just a little superscript -1, but it's same as writing arcsin or arctan. It's just a personal preferrence for some reason....Helps me remember that it's essentially an inverse function.

Last edited by StraightRazorDave; 07-09-2009 at 05:52 AM.

-

07-09-2009, 12:37 PM #29Retired Developer

- Join Date

- Mar 2008

- Location

- Berlin

- Posts

- 3,490

Thanked: 1903

Big fat warning: I hate maths. Always have, always will. It's a truly mutual relationship, by the way.

That said, I am not entirely certain that what you said is entirely accurate. Take a look at the drawing again. We measure B, which is the total spine thickness. Suppose we did not calculate the taped bevel, but just measure the taped spine, in the same fashion as we measure the un-taped spine. Obviously, we are then measuring 2 extra layers (I tried to illustrate that in the drawing as well). So when using the same formula, in the taped version the spine thickness is B+2 layers of tape. It is true that you can easily rewrite the formula (B+2T)/2 = B/2+T. Both are correct. I believe my variant stays closer to what would happen if you were to measure the taped spine instead of calculating it. Quite honestly, I thought that would be simpler.

The rest is, I'm afraid, slightly beyond me. I think that by widening B, also A will become very marginally longer. However, a spine is usually rounded and neither does tape create a sharp corner where it is folded over the rims of the spine. I couldn't think of a formula that completely correlates with how exactly the tape folds around the rim. Moreover, I think this factor will only alter the outcome in amounts far beyond the precision of our measurements (using the Verniers calipers) and far beyond the normal variations in spine thickness and blade width that can be found along the same blade. Variations in thickness of the tape itself will nullify the intended extra precision.

I'm sure this will be an interesting exercise for you mathematicians (and, of course, the Polymaths), but for practical use in real life on real razors, it seems a bit over the top. Personally, knowing the bevel angle within half a degree is more than accurate for my purposes.

I think it would be fun to have that in the Excel spreadsheet for practical purposes.

Thanks a lot!

Robin

-

07-09-2009, 01:24 PM #30Senior Member

- Join Date

- Apr 2007

- Location

- St. Paul, MN, USA

- Posts

- 2,401

Thanked: 335

This is all too fascinating!! I have to admit some confusion about the angle in discussion. Have we come to any agreement on how we are describing the angle as it pertains to half the thickness of the spine or are we talking about the entire included angle which is described by both bevels meeting at one edge?

This may be important as we are told that we need to hold the razor at a 30 degree angle to our properly stretched faces. Now is one side of that 30 degree triangle taken down the center of the the razor or is that side determined by the far side of the edge and the far corner of the spine, as it relates to the face, or is it the near side of the edge and the near corner of the spine as it relates to the face? And has anyone taken into account the thickness of the lather?

And does arcsin mean really, really sharp or is that function yupswell? I have to admit to getting a bit sloppy with my angles, I know there is no excuse for that, but in my defense I am really fussy with yupswells.

Carry on,

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote