Results 1 to 10 of 19

-

01-30-2019, 10:06 PM #1

Soviet rasors NOS - Impossible to take a beve,l or it is just me?

Soviet rasors NOS - Impossible to take a beve,l or it is just me?

I bought these two Soviet era straight razors. They were made in the 70s and never used.

I tried to hone them with poor results. It seems impossible to eliminate the double bevel that I see with the magnifying loop.

I used the Nortons 220, 1000, 4000, 8000

The problem is I cannot create a decent bevel with the first two stones.

I am not the most experienced person in honing, but I manage to keep the rest of my 20 straight razors in excellent conditions and create a decent new bevel when needed.

Does anyone know anything about these kind or razors? Are they indeed impossible to accept a bevel, or the problem is me?

I am thinking of sending them to a professional to hone them, but I don't know if they worth it.

From the seller: "Vintage Russian Straight Razor "Raketa"(Rocket) in Original Case,made at "STIZ" factory in Moscow in middle of 1970's. "

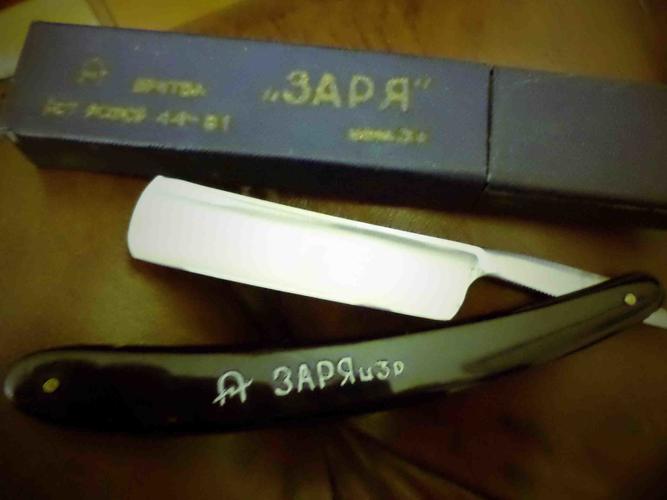

From the seller: "Russian Straight Razor "Zarya"(Dawn) in Original Case NOS in factory grease. Made at "Moselectropribor" factory in Moscow in early 1980's. "

-

01-30-2019, 10:27 PM #2

Are they stainless? The Norton guys could say how they work with SS.

Are they warped ?

Both could be a challenge.“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

-

01-30-2019, 10:33 PM #3Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,251

Thanked: 3222

I only have one Soviet razor which easily took a good edge using a Naniwa progression to 12K. Couldn't tell you the name of the model though. Never really heard much bad said about the blades or the steel.

BobLife is a terminal illness in the end

-

01-30-2019, 10:54 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,395

Thanked: 4821

I had one once and sold it. If I recall correctly it was a little hard, much like a US or French razor and it did ahave very well and help the edge well too. Personally I would drop the 220. It seems like way too much. I also typically hone with one layer of tape but if I’m being delayed in getting a nice apex a sometimes add a layer. The magic marker can also guide you too.

-

01-31-2019, 06:44 AM #5

-

01-31-2019, 08:09 AM #6

Hard steel maybe ?

It's possible a bevel was never set on them. They could be straight off the grinding wheel.“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

-

01-31-2019, 10:27 AM #7

I'm not familiar with Russian razors, but I'm wondering if they might simply be RSO's. They look quite similar to a Pakistani razor I found, years ago.

Mike

-

01-31-2019, 10:34 AM #8

-

01-31-2019, 10:57 AM #9Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,251

Thanked: 3222

I think Russian straight razors are real straight razors and not anything like the Pakistani RSOs I have read about.

All I used to set the bevel on mine was a 1K Naniwa. I have also read that the steel in Russian razors can be hard so I wonder if using a 220k hone is a good idea re chipping. Maybe lighten up on the pressure and take more time setting the bevel on a 1K stone?

BobLife is a terminal illness in the end

-

01-31-2019, 01:26 PM #10Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,091

Thanked: 292

If the razor has a double bevel, it is not necessary to eliminate the second bevel. If the steel is quite hard, the manufacturer may have used a second bevel to make sure they were honing all the way to the apex without removing so much steel. So rather than using a 220 grit stone trying to remove a lot of metal to produce a single bevel, you might consider using the Sharpie test to mark the bevel(s) and then try to use one or more layers of tape to insure that you are honing the bevel closest to the apex.

I have honed old razors on 220 grit before, but always regret doing so as removal of the large scratch marks takes a lot of work, especially if your next stone up is the 1K. It helps to have intermediate stones such as 400 and 800 grit to eliminate the scratches.

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote