Results 1 to 10 of 15

Thread: Edge Repair or Repairable?

-

02-22-2021, 11:46 PM #1Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56 Edge Repair or Repairable?

Edge Repair or Repairable?

This is a blade that the scales are busted so I tried to sharpen it to see if I could get an edge before using some of the scales that I bought (wasting money). It is a "Blue Steel" with a "P&H" logo, so I don't know that there is any particular value to it.

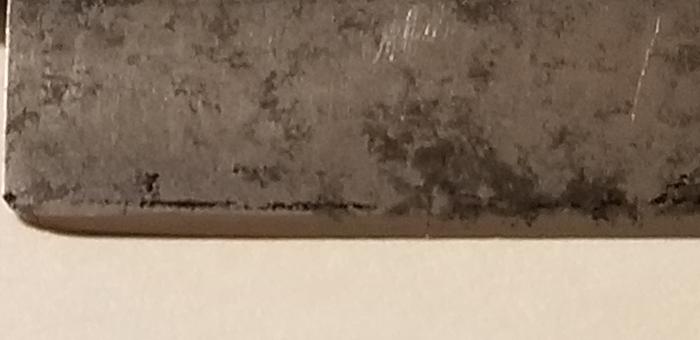

I did the best I can photographing it with a cell phone camera (better than I thought it'd be). I started on diamond plate then went to my 1K stone. But, as I progressed through the stone chips kept forming. You can see on the photo that there is still surface corrosion on the bevel. I guess that the corrosion has damaged the edge so that as I sharpen it it just breaks bits away. So would I just be grinding and grinding away until if may get to nice steel after where those black pits are?

I did not sand this blade, just did some 3M and polishing compound. I for sure think that before I go further I will need to sand the blade and polish up near the edge. My next step was going to be to add two or three layers of tape and go back to the diamond plate to hasten the removal. But is it worth it? It is already less than 5/8", so I may end up with a 4/8" blade by the time I am done.

The photos make it look like there may be a crack in the blade, but there isn't. Also, it looks like the bevel is not fully set, which it isn't, but not as bad as the photo makes it look. There is just a small bit of reflection near where the chips and corrosion are. I don't remember seeing it while I was working on it, so it may have actually be from the masking tape I put on the edge so I don't have a sharp edge in the tool box.

Thanks everyone.

Edit: I probably should have cleaned the blade. A lot of the rich dark black stuff just above the bevel is sharpie.If you're wondering I'm probably being sarcastic.

-

02-23-2021, 12:00 AM #2Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,768

Thanked: 550

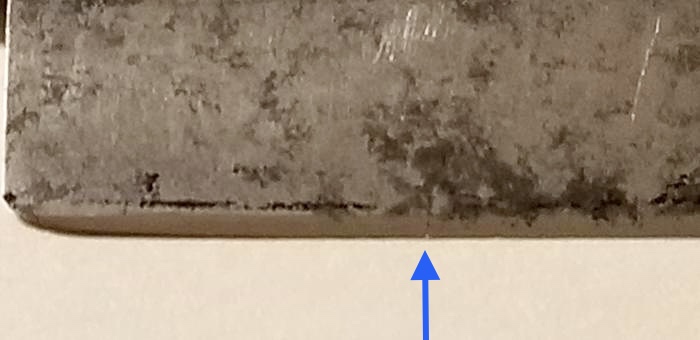

I think you have more than just a chip (blue arrow).

I wonder if your diamond plate is causing microchips to form on the edge at the end of the stria. Have to tried setting the bevel with a 1k or 2k stone instead?

It’s hard to tell if the steel has been weakened by corrosion, but to my eyes, it doesn’t look that bad. I am shaving with razors that started out looking much worse. I’m sure others with more experience and expertise will add to the discussion.David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

The Following User Says Thank You to DZEC For This Useful Post:

planeden (02-23-2021)

-

02-23-2021, 12:10 AM #3Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Thanks DZEC,

I am 90% it came after the diamond plate. Or got worse. I used the 1200 grit side of the diamond plate because before I had chipping from the 400 side. I was pretty focused on this area the whole time, but I have trouble getting a consistent view with my 30X magnifying glass. I am thinking of getting a 5X or 10X and calling that good enough.

But, I am certainly willing to go after it again on my 1K stone and see if it gets worse or better. If nothing else it is practice and experience.If you're wondering I'm probably being sarcastic.

-

02-23-2021, 11:09 AM #4

That’s a crack, and as a whole the diamond plate is rough even at 1200, but that’s a crack

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

The Following User Says Thank You to tcrideshd For This Useful Post:

planeden (02-23-2021)

-

02-23-2021, 11:27 AM #5

I've saved worse looking razors but there appears to be a lot of corrosion at the heel and toe.

It is not clear if you honed all of the corrosion out of these areas. I would go back to a 1000 grit stone and make sure the corrosion is gone. You will need a good loupe or scope to be certain.

That spot does appear to be a crack. If it is a crack it does not mean the blade is lost. It may still shave but could get worse. I've had poor luck saving cracked blades.

Good luckIf you don't care where you are, you are not lost.

-

The Following User Says Thank You to rolodave For This Useful Post:

planeden (02-23-2021)

-

02-23-2021, 12:26 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Looks like advanced Cell Rot, it has eaten the bevel and edge. You will likely need to remove at least half the bevel to get past the crack and the pitting, even then questionable if you will hit good steel.

I would pass on this one. Why are you using masking tape?

-

The Following User Says Thank You to Euclid440 For This Useful Post:

planeden (02-23-2021)

-

02-23-2021, 01:09 PM #7

As Everyone is saying, It looks like a crack to me. Push one side of the crack against your thumbnail. The bevel. See if it moves one side only. You should see a flex of the edge/bevel but as one. But I bet it's a crack. Saving can be done but you're going to need to really hog some steel away to get past it. Unless you have no others to work on I'd pass on this one for now. Just clean it up better and put it away. JMO.

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

planeden (02-23-2021)

-

02-23-2021, 05:15 PM #8Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Thanks guys,

I will double check the crack. Either the camera is at the right angle to pick it up and my loupe is not, or there is some strange shadow. If it turns out to be cracked I will probably put it away or make some windchimes. I have plenty of others to work on. I may anyway, based on some other advices, and that I am excited to get to some of the others i have to work on.

Euclid, I keep these in tackle box. When the blade is not in the scales and I am sharpening the blade, I put masking tape on it to protect the edge and my fingers when it is loose in the tackle box. I try to fold it so it is not actually contacting the edge. I figure that even if I glass the edge it is still pretty thin and can get dinged up and/or cut me if I am not careful.

So, if that is cell rot I suppose it is good that I trashed those scales . I have seen a lot of things talking about cell rot and different scale materials, but with all the other things I am trying to learn, I have not started trying to figure out scale materials.

If you're wondering I'm probably being sarcastic.

. I have seen a lot of things talking about cell rot and different scale materials, but with all the other things I am trying to learn, I have not started trying to figure out scale materials.

If you're wondering I'm probably being sarcastic.

-

02-23-2021, 05:35 PM #9At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,957

- Blog Entries

- 1

Thanked: 13223

What the heck is a Flex Test

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

-

02-23-2021, 05:46 PM #10

Thumb flex test?

Hah, I've been doing that on my scythe blades for decades

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote