Results 1 to 10 of 12

Threaded View

-

12-21-2016, 02:58 AM #1

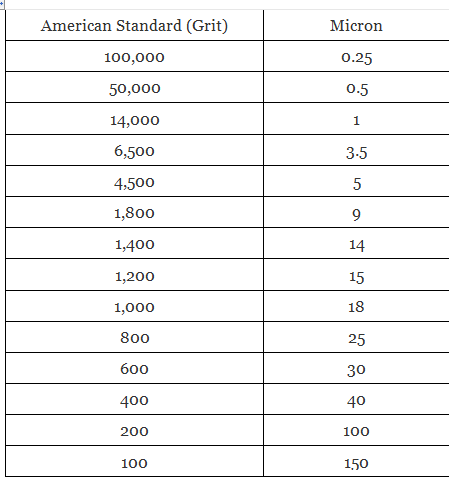

American standard grit chart conversions to microns

American standard grit chart conversions to microns

I ran across this chart and am trying to understand and associate it with hones and diamond paste. If you look at 1000 it lines up with 18 microns.

So my question is this - If you have diamond paste that says it's 1 micron is that equivalent to a honing stone that is a 14000 one?

I would really like to understand how this works. Can anyone help me understand?

Semper Fi !

Semper Fi !

John

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote