Results 1 to 10 of 19

Threaded View

-

10-17-2015, 09:18 PM #1

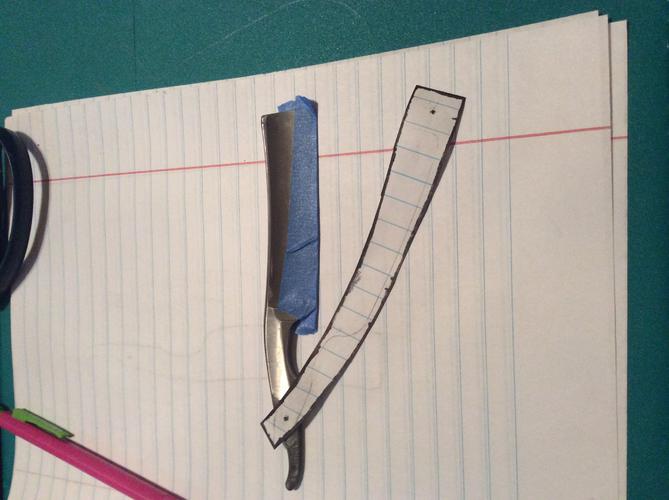

My first set of horn scales fail Joseph Roders

My first set of horn scales fail Joseph Roders

This razor restore drove me up a wall I even was up really late trying to make it work... My issue with this restore was that the blade was closing to the left all the way to the middle of the blade on the mock...

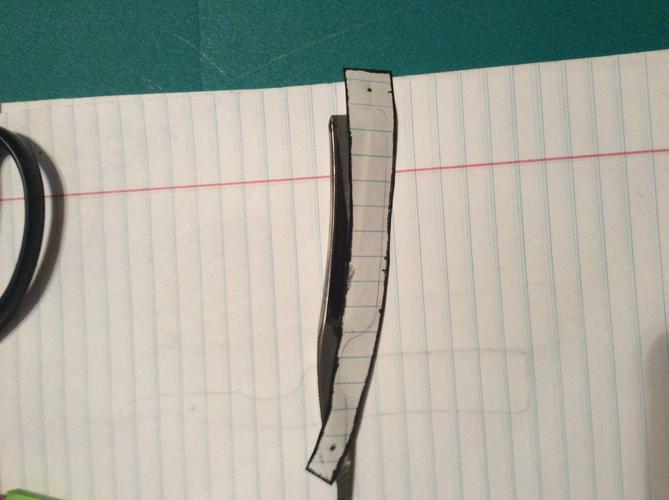

So here goes the breakdown of everything I did step by step to see what could have caused the issue... First off the horn was cut in half by me with a bandsaw being that it was 5mm think, I was going to try and fit it on one blank but it wasn't wide enough, So I had to use both sides of the cut for my scales... After I was done cutting the rough shape I realized the scales weren't flat, I then got double sided tape and clamped them together which did work very well to flatten them together for shaping... I drilled the wholes for the pins in which on one side looked center and the other looked a slew, I pressed on... while shaping I realized that one side of the horn was thinner than the rest due to my poorly cut horn... I pressed on and I had shaped them to the thickness at its thinnest point just so it could be even, which I believe turned out fine... Everything was looking great, from the belt sander 80-400 hand sanding 500-1200 took the tape off and set up the mock and that's when I hit the issue....

Had it been because of the miscut warped horn? The holes for the pivot pin not being centered on one side? Here are some pics I took, I didn't take much after it was done because it frustrated me so much lol so I may have screwed myself for a conclusion... I still have the horn so if more pics of that are needed

Oh this is my first set I had ever drawn out and not used a template

I only finished the razor just so I could see what it would have looked like... I also tried to use 2 washers on one side, which honestly seeing how that made the razor look is something I'll never do again....

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote