Results 11 to 20 of 28

Thread: Recycled steel

-

03-10-2012, 12:58 PM #11aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

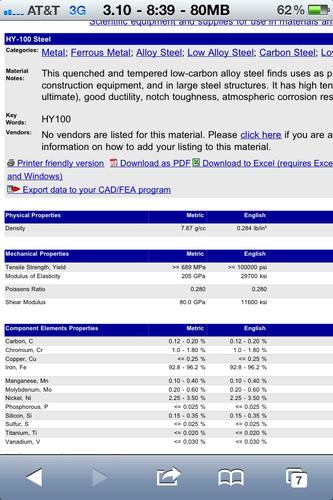

Yes, Los Angeles class submarines are made of spring steel called HY100. I remember that one from sub-school...

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-10-2012, 02:28 PM #12

This topic comes up ALL THE TIME on blade forums. So often they have a sticky in their workshop forum about it.

The general consensus is this: while it's neat to make something from another object, thus recycling and extending the useful life of the steel, it is almost always more cost effective to buy a known steel type. You'll know what it is, where it came from, and most importantly how to heat treat it. Without a good heat treat you will just have a razor shaped object.

Look up Aldo Bruno at NJ Steel Baron. He has a lot of different steel and is a great guy to work with. His 1084 is high Mn, and is SOFT. It's cheap and easy to forge too. His prices beat literally every other place I've checked. And if his website doesn't show a steel type (O1 for example) call him. Not only is he helpful, he's a hoot to talk to. He is in the process of updating his website completely, so a lot of his inventory is not up there yet. He will help you out.

-

The Following User Says Thank You to medicevans For This Useful Post:

jeness (03-10-2012)

-

03-10-2012, 02:34 PM #13

I just saw this part of your post.

Step 1: call Aldo and order 5/16x1 1/4 O1.

Step 2: grind everything away that doesn't look like a razor

Step 3: send to Mike Blue for HT. Ask for austemper. Make sure to pepper him with all sorts of inane newbie steel geek questions like I did. He's entirely too patient. Lol

Make sure to pepper him with all sorts of inane newbie steel geek questions like I did. He's entirely too patient. Lol

Step 4: enjoy!

This is my O1 stock removal razor. Ht by Mike. My first but not my last.

-

The Following User Says Thank You to medicevans For This Useful Post:

jeness (03-10-2012)

-

03-10-2012, 02:42 PM #14

-

03-10-2012, 03:00 PM #15Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

One good old Leaf spring should yield a couple dozens razors for sure!!

-

03-10-2012, 03:11 PM #16

Provided you know what steel it is 100%.

OR......

Call Aldo and get a 7/8"x40" round stock 5160 for $25 and KNOW all the hard work, time, and money you put into making razors isn't wasted by saving pennies on steel.

Time is the major cost in knife and razor making, not steel. Don't be penny wise and pound foolish.

-

03-10-2012, 03:18 PM #17

I know, I started as a knife guy

I have made a few knives, and now 2 razors, I already know something about steel from a lot of sources and reading. Thats why I asked specifically about usage regarding razors, because if a steel makes a good knife, it doesn't mean it makes a good razor

I have made a few knives, and now 2 razors, I already know something about steel from a lot of sources and reading. Thats why I asked specifically about usage regarding razors, because if a steel makes a good knife, it doesn't mean it makes a good razor  It will probably, but not necessary.

It will probably, but not necessary.

I want to do stock removal and forging parallel, I will use mystery steel only for forging, and as long as I learn to forge properly. It would be a shame to spend 100$ on steel, which I overheat, and wreck with bad forging technique.

Thanks for the advice on steel buying, the only problem is that I am in Europe, and good steels are not readily available as in the US. The only steel I can buy if I am lucky is 6mm thick O1, and thats it. O1 is nice, but a bit expensive to learn forging on, but perfect for stock removal.

I have a friend here who makes the HT for me locally in a factory, and they are very good, so I am not considering to do it on my own

-

03-10-2012, 03:22 PM #18

IF you can buy that stock I would be glad to pay the price for it, if it would be available for me. The distributors here get you the steel you want only if you buy about 1 ton of it... No joke, 1000kg of steel, or they won't even import it from Sweden or Germany. You are lucky over the seas, we are even struggling to find a steel that is about as good as 1095 or 1084, or even 5160.

I would be glad to pay the price for it, if it would be available for me. The distributors here get you the steel you want only if you buy about 1 ton of it... No joke, 1000kg of steel, or they won't even import it from Sweden or Germany. You are lucky over the seas, we are even struggling to find a steel that is about as good as 1095 or 1084, or even 5160.

-

03-10-2012, 03:34 PM #19

See, this is what I get for not checking your profile first. Dang. Well, I got nutin' then. I still stand by my statement of buying known steel, but past that, I don't know how Hungary is.

I wonder how much flat rate of two or three bars cut to 8" or so then flat posted to you would cost? If you really can't get good steel, it might be worth it. 1084 is cheap enough, you might be able to get it shipped for not a whole lot total cost if you were ok with it being cut to shorter than 1 metre lengths.

-

The Following User Says Thank You to medicevans For This Useful Post:

jeness (03-10-2012)

-

03-10-2012, 03:39 PM #20

Well, this is a possibility too, I thought about it. If I won't have any luck, than that will be my best bet. I can buy round stock from Böhler K510 here, but the minimum is quiet a bit. When I will know how to forge, than I will buy a few kilos of that steel.

7Likes

7Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote