Results 21 to 30 of 31

Thread: Edge doesn't last long.

-

10-26-2017, 07:46 AM #21Member

- Join Date

- Dec 2012

- Location

- Portsmouth, UK

- Posts

- 33

Thanked: 0

Cheers!

I can't see any light reflecting along the edge, but I do rather struggle with using the loupe; I think I'll get a usb microscope so I can more easily inspect the blade.

-

10-26-2017, 11:42 AM #22

Sage advice!

I knew this was out there somewhere and I should do this myself, have on old vintage blade with a ton of spine wear and I jus't cant set the bevel along the entire edge on it without tape, I think I should try to do a calculation to see how many layers would be optimal, that way these blades are not 'lost' and can still function, I have a couple very worn razors somewhere, with a little tape I can give these a second life! Pretty neat!

-

10-26-2017, 02:46 PM #23Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,251

Thanked: 3222

-

10-26-2017, 10:14 PM #24

-

10-26-2017, 10:48 PM #25Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Careful you don't fall into the trap of ever increasing magnification. The more you magnify the edge, the worse it looks. The worse it looks, the more you're going to chase it. And there is a point of diminishing returns, if you can't see it at 30x magnification the 'problem' is (literally) microscopic and likely not affecting your shave or the edge's durability.

I'd wager the steel toward the edge is a bit on the frangible side. So my next question is what are you using to hone with? What I would try is very lightly - just so it's barely touching - drag the edge over the corner of a high grit (8K or so) hone. 2 times, maybe 3 - just enough to pick at the edge and knock away any weak/chippy steel. Then I'd work it on a medium grit stone, say a Norton 4K in my case, until the bevel was reset. From there I'd sneak up on the final edge with a natural stone. Take it slow and easy on a not so aggressive stone (Welsh slate maybe?) and see how long that lasts.

-

10-26-2017, 11:29 PM #26Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,251

Thanked: 3222 Life is a terminal illness in the end

Life is a terminal illness in the end

-

10-27-2017, 01:05 AM #27

I have honed a few razors, especially thin hollow ground ones, and taken them up to a 16k Shapton Glass stone where the edge didn't last very long at all. Going too high with the grit sometimes makes the edge so thin that it breaks down really fast.

The last one looked great under magnification when the honing was finished. It started to feel funny during the test shave. When I looked at it afterwards, the edge was pretty badly chipped, and that was after one shave.

Using too high of a grit is not always the answer, especially on some blades that are really thinly ground.

Pete <:-}"Life is short, Break the Rules. Forgive quickly, Kiss Slowly,

Love truly, Laugh uncontrollably, And never regret ANYTHING

That makes you smile." - Mark Twain

-

10-27-2017, 04:37 AM #28

Nice! It's true, spending too much time making razors has skewed my thinking towards 'permanent' honing solutions. Had to resist the urge to reset the bevel on a near-wedge someone brought in today. It had normal hone wear on the spine but the last person to work on it had used a bunch of tape anyway. Took 3 layers to match, and it shaved just fine so I guess I have no real complaints! There's more than one way to skin a cat.

-

10-28-2017, 10:34 AM #29Member

- Join Date

- Dec 2012

- Location

- Portsmouth, UK

- Posts

- 33

Thanked: 0

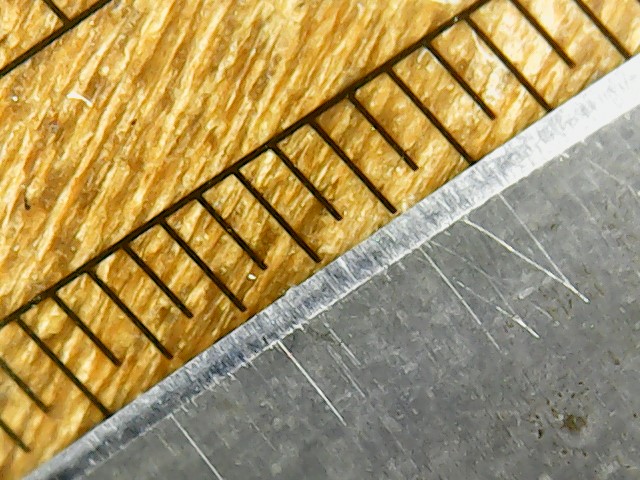

The magnification isn't very good, and I'm not really sure what it 'should' look like:

-

10-29-2017, 01:16 PM #30Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Good point, it is possible to hone a razor finer than the steel can handle. But the OP is only using an 8K hone not a 16/20/30k hone, and my suggestion wasn't to take the edge to that level.

Grenage - looking at your photos 2 things are standing out. The section of blade in that second picture seems to have chips or dings. Your edge should be perfectly straight. More like the first and third pictures. The other thing is what appear to be stria going parallel with the edge. I'm not sure if anyone has linked it yet, but this thread is my go to when people new to magnification have questions because it probably has all the answers (and tons of pictures to look at and compare with):

http://straightrazorpalace.com/honin...ggestions.html

38Likes

38Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote