Results 1 to 9 of 9

-

05-04-2011, 04:47 AM #1

x-pattern leads to honed out toe?

x-pattern leads to honed out toe?

I'm watching the DVD honing section from SRD. I am still puzzling on the x pattern "heel to toe". (Incidentally, I see neither "heel" nor "toe" at Basic straight razor anatomy, though it is in the video if I remember correctly.**)

In any event, using the terminology from the wiki, it seems to me that if you always pull, the point of the razor will be in contact with the stone a greater percentage of the time than the other side.

So my question is, why doesn't this inequity lead to asymmetry on the razor?

** memory is a problem in my case. It would be nice if we made the annatomy shown in the wiki consistent with the DVD.Last edited by MikeMN; 05-04-2011 at 04:52 AM.

-

05-04-2011, 04:56 AM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

You have asked one of the eternal questions. The answer is because the pressure is varied during the honing stroke in order to prevent this. If you have read of any descriptions of the rolling-X stroke, the pressure is to be pretty much be focused on the edge of the hone during the entire stroke, so the cutting action along the bevel transfers from the heel to the toe during the stroke.

-

05-04-2011, 05:00 AM #3

In conjunction with what Ron (Utopian) said about the pressure, if you look closely at your razors while honing, you will see that on most razors, even those that appear to have a straight edge, the entire razor does not actually contact the hone all the time. On very nearly ever razor that I hone, I am doing a very slight rolling X, which is pretty much what Ron is saying about the pressure being at the edge of the hone. I think of it as the intent of a rolling X, even though there is no pronounced roll. YMMV and I'm sure others do it differently, but that is how I roll.

-

05-04-2011, 05:12 AM #4This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,623

- Blog Entries

- 2

Thanked: 1371

The hone companies put more abrasive grit at the edge of the hones in anticipation of that problem.

You need to specify when buying hones that they are for "x" strokes and not straight strokes.

(or maybe I'm just BS'ing because the question was already answered above)

Strange women lying in ponds distributing swords is no basis for a system of government.

-

05-04-2011, 05:15 AM #5illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

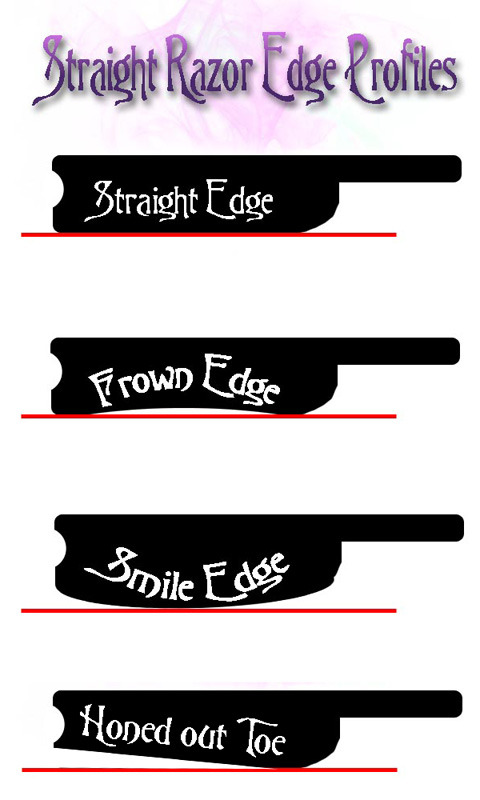

Actually a corollary to your question could be "why do so many razors end up with a frown?"

The answer to that related question that you did not ask is that the tendency of a bad honer is often to keep the pressure uniformly toward the heel and so, again at the edge of the hone. As the X-stroke proceeds, the center of the blade is subjected to the greatest amount of cutting action and so wears the fastest. Now, that DOES relate to your original question, because it all comes down to the application of variable pressure of the blade on the hone. IF theoretically you could robotically and perfectly keep the pressure of the blade uniformly constant along the length of the blade, which as Holli4pirating pointed is impossible, then the result would be your image of the honed out toe, because the heel would be exposed to the least wear and the toe to the greatest.

-

05-04-2011, 05:53 AM #6

I was actually pondering what a good robotic arm might look like. I imagined it with a variable, multi-point damping and pivoting mount to allow varied pressures and angles for the one stroke to rule them all, and in the darkness hone them. It was a fun thought exercise...

-

05-04-2011, 06:38 AM #7illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

-

05-04-2011, 12:23 PM #8

Thanks guys. Randy Dance is going to show me how he hones soon, and I've been trying to study in advance.

-

05-04-2011, 01:01 PM #9illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

In that case you will be in very good hands. He is an excellent teacher. In fact, I had him teach my wife how to hone. (There are some jobs you've just got to leave to someone else and this was one of them!) Randy will get you off to a great start.

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote