Results 1 to 10 of 15

Thread: I need help with this razor

-

11-29-2011, 04:35 AM #1

I need help with this razor

I need help with this razor

Ok guys I need help with this razor. I can't figure out what is going on. I have tried several things with this razor and get the same results. What makes it even more frustrating for me is that i have three razors that I have honed that are working well. This one and a few others not so much.

I am not the world's best photographer but I did the best I could here. These were taken through my engraving microscope at 20X. I dont' know how much the camera enlarged it but these pics have to be at least 40-50X. maybe more.

I'm going to walk through what I did with pics and see if you guys can figure out where things are going south.

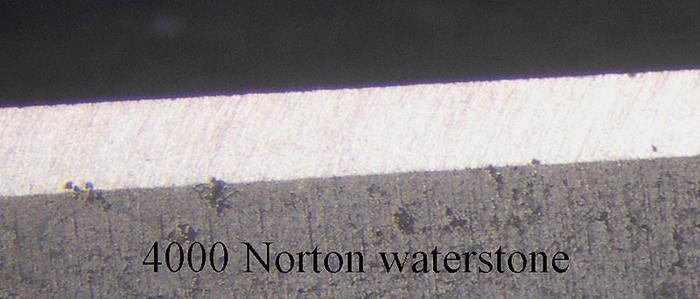

This first pic is with the 4000 norton waterstone where I started.

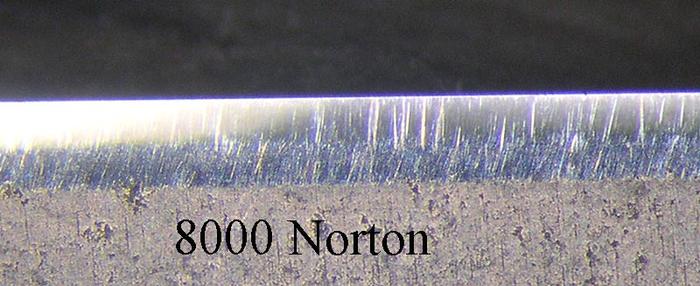

This second pic is the 8000 norton. Now weird things were happening here. I keep feeling like mystery grit is magically appearing on the stone surface. I would wash it off and it would come back. I even re-lapped the face of the stone and it came back. It was almost as if little pieces were crumbling off the edge of the razor or off the stone and floating around on the surface. You can even see little scratches in the bevel from this.

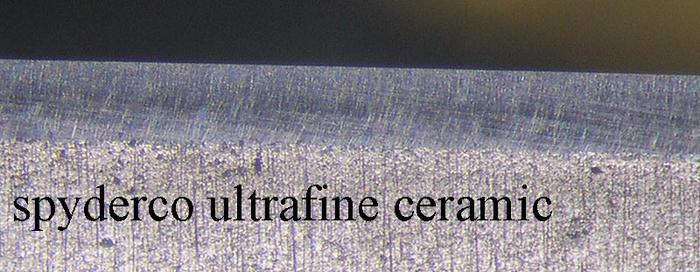

This third pic is of the finish stone. This time I used my "ultra fine" spyderco ceramic (the finest one they make in the black box). At this point the edge looks pretty clean to me. It has even cleaned up the scratches form the stray mystery grit from the norton 8000

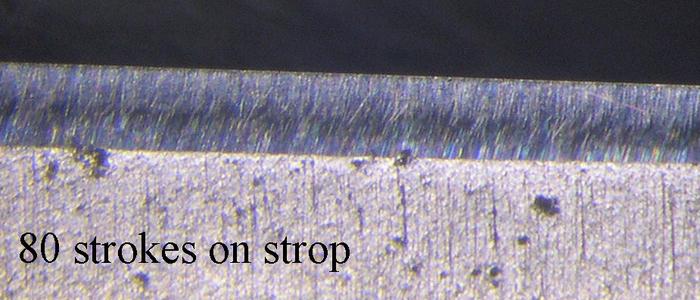

Next we have 80- strokes on the strop. I am using a "Tiger Brand" Illinois #976 with no compounds of any kind. Leather side only.

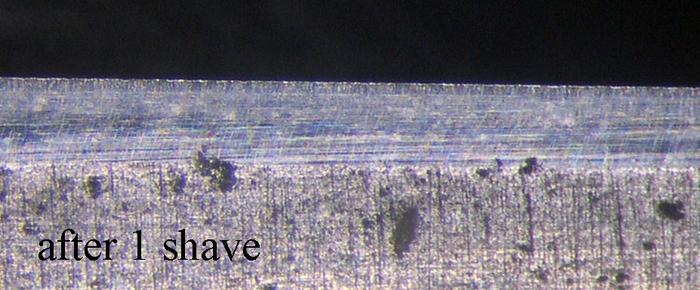

So now I try and shave with it. My right cheek and even my right neck are fine but by time I get to my left side it acts as if the edge has fallen apart. You can see in this last pic that the very edge is actually rippled.

I have also tried a Chinese water stone and also my translucent hard Arkansas as a finishing stone and I get the same result with this razor. I have tried a leather bench lap with semicrhome and I get the same result. I have tried a leather bench lap with 50K diamond spray and the same result. I get a little shinier edge and bevel with the leather laps but the edge fails the exact same way.

As I said the really frustrating thing for me is that I have a few razors (henkels, keen kutter, robeson suredge) that I treat the same way and get much much better results from.

Any idea guys?

Ray

-

11-29-2011, 05:00 AM #2

It would be better for everyone if we knew what this razor is.

It may be that it is a Sheffield blade and they (apparently) don't take a very fine edge (ie very fine hones), even though they can be really good shavers (mine are).

That's about as much help as I can be, I'm afraid.Hang on and enjoy the ride...

-

The Following User Says Thank You to Havachat45 For This Useful Post:

RayCover (11-29-2011)

-

11-29-2011, 05:14 AM #3

It looks to me like you spent too much time on the finishing hones and worked the edge to thin. The thin edge has little support and that is why it failed.

Last edited by Kingfish; 11-29-2011 at 05:25 AM.

-

The Following User Says Thank You to Kingfish For This Useful Post:

RayCover (11-29-2011)

-

11-29-2011, 05:20 AM #4Hones/Honing/Master Barber

- Join Date

- Aug 2009

- Location

- Waynesboro, PA

- Posts

- 997

- Blog Entries

- 6

Thanked: 199

For the N8k, I think I remember hearing some people had to lap a good bit of the surface off because they were finding particles in the hone. I didn't have that problem with mine, but I would keep lapping it. Take some time on it, and then try it again.

As far as your problem, I can't say exactly, but, let me ask this; did you put a secondary bevel on the edge? I can't tell from the 4k pic because of the glare, but on the 8k pic, you can clearly see that you are not hitting the whole bevel with the 8k stone. On the last pic, why does it look to me that you have scratch marks running parallel with the edge? I don't know if it's the photo, or the razor, but I see a line running parallel to the edge about 1/8th of the way down from the cutting edge of the bevel...makes me think there is another bevel there.

As far as the edge falling apart after the right side of your face, do you switch hands when shaving? Or does the same side of the razor always face your face?

I ask because to me, it sounds like the bevel isn't set right.

I say that because I had a razor that I was honing, and I could take a couple swipes to my face, and it would cut ok, but then it would go down hill fast. After going back to my bevel setter and taking my time making sure both sides of the bevel were up to par, I finished it off and it worked great from there on out.

I know people will say if it cuts hair, the bevel is set on both sides, but I swear, I have had blades that one side would ping hairs great off my arm, but when I flipped the razor over, hitting the hair from the same direction, there were spots on the other side that wouldn't cut anything. I don't know the exact reason for this, but this is how I can tell when I can move from my bevel setter to the 4k+. I would spend more time until both sides popped hairs equally well along the whole edge, and they honed up great then.

What kind of razor is it, just out of curiosity?

-

The Following User Says Thank You to avatar1999 For This Useful Post:

RayCover (11-29-2011)

-

11-29-2011, 01:46 PM #5

Thanks for the input guys. L:et me see if I can answer some questions.

The razor is an ERN Crown and Sword made in Wald.

The parallel lines in the last pic are smears of soap or something that I just didn't get cleaned off after the save.

I do switch hands from one side of my face to the other.

I am trying to be very careful to keep the edge bevel and the spine flat against the stone as I hone. I also saw that reflection in the second pic that looked like a secondary bevel. If that is a secondary bevel what am I doing to create it? That reflection is gone in the next pic though so it may just be light playing int he photo. Don't know for sure.

I know you can't tell from the pics, but I don't think I am creating a bur that is rolling but that is possible. If I am it is too small for me to see under the scope.

I buy the idea on the 8K Norton needing lapped down to a certain point. That would explain the mystery grit that kept appearing even after lapping and washing the stone face. I will try that.

Kingfish,

I need to understand better what your telling me. When your talking about to thin of an edge, how does that happen if the idea is to use the spine and the edge to set he angle? It was my understanding that you wanted a perfect geometric angle at that edge with no radius what so ever. In other words bring the two angles down so they meet perfectly and theoretically have no thickness at the edge. I realize that in reality you must have some thickness or you have air but I don't know how else to explain it. Are you talking about a burr hanging on the edge? Are you recommending that I put a piece of tape on the spine to beef up the angle a bit?

RayLast edited by RayCover; 11-29-2011 at 01:49 PM.

-

11-29-2011, 11:41 PM #6

Hi Ray,

I don't think the perfect edge by looks is always going to work with a good time to put the hone down. After your bevel is set and you get to say an 8k level and beyond it is very easy to overwork the edge and though it may look pretty it just does not perform. Maybe the perfect shaving edge has just a little more complexity than two angles meeting at a zero point

-

11-29-2011, 11:55 PM #7

In the 8k norton pic it looks as if you have two scratch patterns, I am wondering if you created a double bevel and then rounded it in the next step. In the last pic I can see two scratch patterns as well.

Last edited by nun2sharp; 11-30-2011 at 12:01 AM.

It is easier to fool people than to convince them they have been fooled. Twain

-

11-30-2011, 12:04 AM #8

Maybe it's just me - but if I saw one of my razors looking like what I think I'm seeing in the norton 8k image - I'd go to a 1k and reset the bevel.

While there doesn't appear to be anything off in the 4k image - it's not shot at the same angle so it's hard to tell. Still - I think I see two distinctly differnt patterns in the 8k image. Where the bevel angles into the blade, that section looks like the pattern from the 4k image. The section of the bevel closest to the edge looks more like an 8k bevel to me.. as if you're not making contact with the stone all the way up the bevel. This would mean the cutting edge is being pushed into the stone.

Particles - are you wiping the blade off with a fabric towel inbetween strokes by any chance? Towels can leave bits of fiber in the scratches and they can get into the swarf and they will wreak havoc on the edge. Feels and looks like weirdo particle bits.

-

11-30-2011, 12:07 AM #9

Nun2sharp,

I don't know what the deal is that I can get some razors sharp and others not. I thought I saw your name on the list for the KC meet on Sat. I really hope you show up and can help me get this straightened out. I will bring all my stones, my razors, strop, etc. in the hopes that you guys can figure out what I'm doing wrong on this razor.

Ray

-

11-30-2011, 12:10 AM #10

I personally don't think that continuing to hone an already sharp blade will make the edge too thin. If you hone correctly and maintain your angle, then you might remove more steel than is necessary but the bevel angles should be maintained and the edge thickness will not be diminished. I've had two blades that seemed to do what yours is doing. In those cases, I just honed them again, and they seem to fine now. My only guess is that, in honing them again, I went through some bad steel and got to some better steel. That's just a guess. If it were my blade, I would rehone it, starting mildly on 4K with little pressure.

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote