Results 11 to 20 of 22

Thread: Iwasaki Tamahagane Information

Threaded View

-

09-07-2018, 06:33 PM #1

Iwasaki Tamahagane Information

Iwasaki Tamahagane Information

I copied this post from the Buy/Sell/Trade section. I thought this forum would be a better place for discussion.

Here is the razor:

The tip was broken off by an accident involving a display cabinet.

These are my initial results from working with the tip of the broken Iwasaki Tamahagani razor. Please remember, this only shows the results involving this blade tip from this razor. These findings should not be taken as being representative of all Iwasaki tamahagane razors.

The sectioned tip. Sadly, the thinnest part broke off. I will try to make a sample from it in the future.

Honing angle - 17.6 degrees

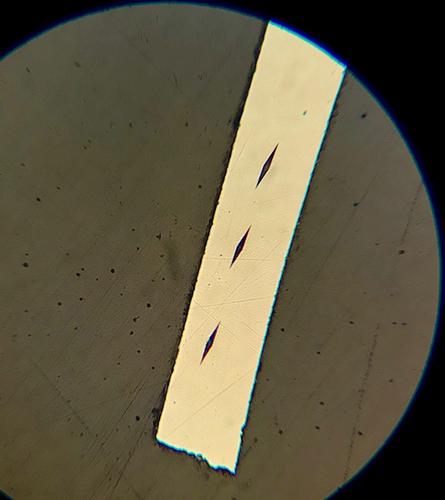

Micro-hardness tester marks. These are shown through my regular microscope using an adapter from Amazon and my iPhone.

Hardness - 62.8 HRC (Converted from Knoop values). I was a little surprised by this. Iwasaki razors have a reputation of being very hard.

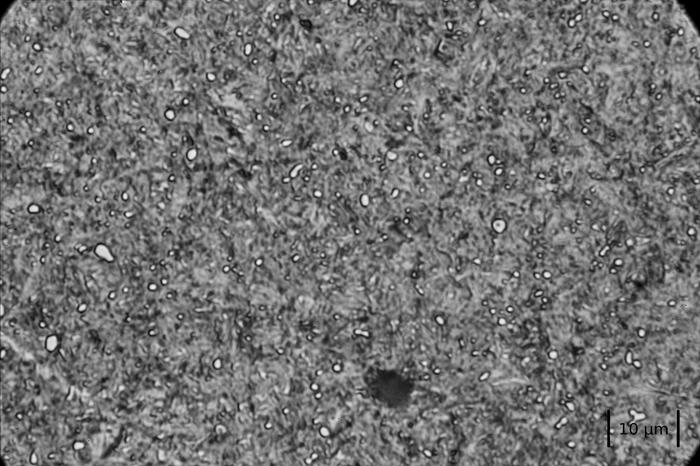

This is very fine martensite with a lot of excess carbides. In tamahagane, the carbides should be cementite. This much excess carbide in the martensite shows the steel is very high Carbon. My guess is 1%, or more.

The large dark spot is the only substantial inclusion in the entire blade section. It is likely Silica. The smaller dark spots are also inclusions. But, they are so small, they are inconsequential. There is no evidence of weld seams from folding and welding.

This also shows a lot of Carbon! There is laminar pearlite as well as spheroidal cementite. I shifted the light a bit to make the cementite stand out. As in the martensite photo, the steel is very clean. This leads me to think that Iwasaki came up with a way to refine the tamahagane that did not use the traditional folding and welding.

Overall, the steel is very high Carbon, and very clean. This is very uncharacteristic for forge welded tamahagane. There are very few inclusions of any kind.There is no evidence of forge welding. It is possible the raw tamahagane was re-melted in a crucible, and then forged to bars and blades. This is my current "guess".

That's all for now. More to follow.

-

The Following 5 Users Say Thank You to Tim Zowada For This Useful Post:

dinnermint (09-08-2018), RezDog (09-08-2018), sharptonn (09-08-2018), Substance (09-07-2018), TMILO (05-10-2019)

98Likes

98Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote