Results 1 to 6 of 6

11Likes

11Likes

Thread: F.W. Engels....learning curve.

Threaded View

-

12-08-2013, 09:00 AM #1

F.W. Engels....learning curve.

F.W. Engels....learning curve.

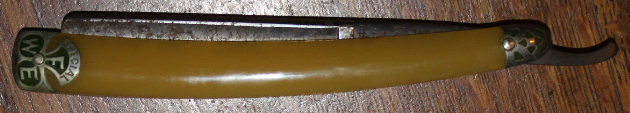

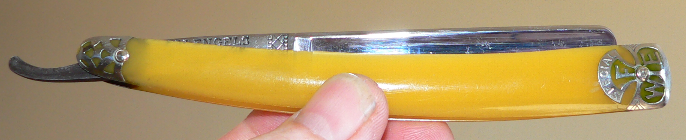

I don't have a lot of experience with these types of blades. I think it's an extra hollow, but will defer to you guys.

These razors are not uncommon, so someone here will have worked on one before and can help me out.

The thing is, it's THIN, and after getting it I decided to start off with #600 wet'n'dry as I didn't think the rust was

too deep....WRONG !!....After continuing with 800, 1000, 1200, 1500, 2000, 2500 I was left with a shiny, serviceable

blade. Plenty of pits and whatnot left but still a vast improvement if I say so myself.

I was worried that if I started at #320 or 400 I might take too much steel off and weaken the integrity of the blade,

just to get rid of some more pitting. Not all of it, just some more.

Anyway, here are some pics, and I look forward to your comments and observations.

Hopefully you can distinguish between the vendors (before) and my (after) pics

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote