Results 1 to 10 of 27

Thread: Pressed Horn

-

01-17-2014, 05:17 AM #1

Pressed Horn

Pressed Horn

Fun and will get you kicked out of the neighborhood for pollution. They say in old methods the temperature for pressing horn is that of melting lead.

This video may help out.

From the-making-of-abbeyhorn-shoe-horns/

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

-

01-17-2014, 05:36 AM #2

I messed around with pressing designs into horn and I found out it would take alot more than I have to do anything serious. Just as an experiment I steamed a piece of horn till it was pretty soft and pressed a metal design into it with a vise and the design was in there somewhat, but wasn't that deep and once the horn heated up again it returned to its natural state and the design was gone. I think there was a post on here awhile ago about needing alot of pressure "as in tons of pressure" and a really hot die and heated horn to be able to keep it from resorting back to its original state. If only I could find some of the old dies or be able to make new ones it would be fun to mess around with.

-

01-17-2014, 01:31 PM #3Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

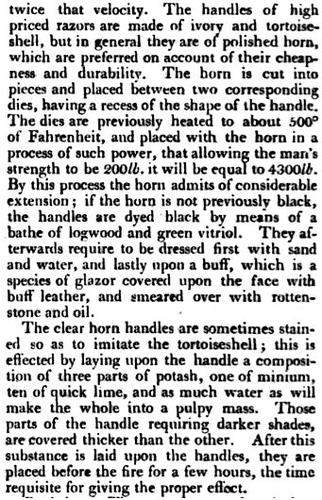

Was somewhat interested in the making of horn scales old school, here a small article from an Encyclopedia from 1813. Also has the process to make faux tortoise looking scales.

-

-

01-17-2014, 04:07 PM #4

Temperature correct or so, A 12 ton hydraulic press should do the job. A heated hydraulic lab press would be tits!

The stink.............Awesome Eau de Burning Hair until the dies cool down and then again for the rough sanding. I don't mind making horn scales until I get the horn over a certain temperature in the cutting or sanding.

Then the chemicals...a witches brew!

Potash /ˈpɒtæʃ/ is any of various mined and manufactured salts that contain potassium in water-soluble form.[1] The name derives from "pot ash", which refers to plant ashes soaked in water in a pot, the primary means of manufacturing the product before the industrial era. The word "potassium" is derived from potash.[2]

Minium is the naturally occurring form of lead tetroxide, Pb2+2Pb4+O4 also known as red lead. Minium is a light-to-vivid red and may have brown-to-yellow tints. It typically occurs in scaly-to-earthy masses. It crystallizes in the tetragonal crystal system.[1]

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline crystalline solid at room temperature. The broadly used term "lime" connotes calcium-containing inorganic materials, which include carbonates, oxides and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominate, such as limestone. By contrast, "quicklime" specifically applies to a single chemical compound.

I wonder about the life expectancy of a horn dyer?

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

-

01-17-2014, 04:09 PM #5

Hey, Mods,

Would it be possible to break off the section here about horn to a new thread. This is getting interesting!

Thank you!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

01-17-2014, 05:02 PM #6

-

01-17-2014, 08:30 PM #7

..this might be totally wrong and it is just a wild idea... so as far as I know

- horn is ceratine, and hair is ... (mainly)

- in the 60-70s women used to do their curles (I am sorry but can not remember the expression, I think it's perm)... it was done (if I remember right from my biochemistry lectured ) that the hair were made in the manner that the hair were wind around the (thingy" and than thiese disulphide bonds (connecting 2 neighbouring ceratine filaments) were broken (reduced), and later again formed with the small difference,.. they were formed between different sulphides (due to neighbouring filaments "sliding" along each other because of winding them ) ..

) that the hair were made in the manner that the hair were wind around the (thingy" and than thiese disulphide bonds (connecting 2 neighbouring ceratine filaments) were broken (reduced), and later again formed with the small difference,.. they were formed between different sulphides (due to neighbouring filaments "sliding" along each other because of winding them ) ..

..so to sum / project my idea on this prioblem ... a heat and REDUCING agent (might be the same thing than women used or stronger reducents,.. ps. reducents are toxic as well but are like the ones for the hair less concetrated and/or "potent"), , tahn pressure (eg straightening) and at the end reformation of S-S bonds (disuphide bridges) .. might facilitate the forced form of the horn (plates)

... a heat and REDUCING agent (might be the same thing than women used or stronger reducents,.. ps. reducents are toxic as well but are like the ones for the hair less concetrated and/or "potent"), , tahn pressure (eg straightening) and at the end reformation of S-S bonds (disuphide bridges) .. might facilitate the forced form of the horn (plates)

ps. again, this is just an idea that might be a miss

pps. a fisrst thing that woudl be good to know should be if the S-S bonds are also as important or aboundant as in a haid fibres...

-

01-18-2014, 02:34 AM #8

I have read about using Hydrogen peroxide as a bleaching and softening agent for horn in musty texts of yore.

I tried it. The difficulty is that the modern commercial beauty shop use version just isn't strong enough to do the job. Lab grade should be a better bet. I think we would need at least 50% -75% solution. I am not one to set up a still to fraction that out of home beauty shop solution.

That reaction plus the burning keratin would need an industrial strength fume hood..as if the horn cooking was not enough!

Interesting!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

01-18-2014, 08:16 AM #9

-

01-18-2014, 08:26 AM #10No that's not me in the picture

- Join Date

- May 2013

- Location

- Los Angeles South Bay

- Posts

- 1,340

Thanked: 284

Yes be very very careful with high concentrate peroxide. I've had some experience with it and the horror stories from the trainers are folks that try to make high concentrate at home, and once they reach the tipping point, next thing they know the kitchen is on fire. You've got the oxidizer built in and take off scary quick.

As part of training we poured 90% H2O2 onto a normal tennis shoe. It was like a torch. No igniter needed - just reaction with the organics.I love living in the past...

-

The Following User Says Thank You to RoyalCake For This Useful Post:

Geezer (01-18-2014)

45Likes

45Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote