Results 1 to 10 of 22

-

03-12-2020, 05:51 PM #1Member

- Join Date

- Jan 2020

- Location

- DFW, Texas

- Posts

- 91

Thanked: 5 Using a dremel for removing black rust, pitting and polishing after handsanding.

Using a dremel for removing black rust, pitting and polishing after handsanding.

I plan to sand by hand up to 7k grit. Would a Dremel wire brush and polishing accessories be useful in both removing the black/rust/pitted areas and taking it all the way from the 7k grit sanding?

-

03-12-2020, 06:15 PM #2

In short, yes.

BUT, dremels are difficult to control. Evenly removing steel is quite difficult. I would recommend not using one or any power tool.

Start with scraping off the rust with a DE or SE blade, then use some 0000 steel wool and then some metal polish. You would be surprised how well this works on most blades.

Why up 7000 grit? Seems a bit overkill, even to get a mirror finish...

-

03-12-2020, 06:43 PM #3Member

- Join Date

- Jan 2020

- Location

- DFW, Texas

- Posts

- 91

Thanked: 5

-

03-12-2020, 07:49 PM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

It depends on how deep the damage is.

Removing a pit is a misnomer, you do not remove a pit, you remove all the surrounding hardened steel to the depth of the good steel at the bottom of the pit.

It can be hard to do with a Dremel and small drum, wire brush will not remove much steel. Unless you have some experience with a Dremel, it can be dangerous for the razor and you. Dremel spin at speeds up to 35,000 rpm, buffers 1,750-3,500. One slip and it can get away from you.

1-2K will get to near mirror, you can polish with any good metal polish from there.

Polishing is easy, the work is removing steel to the depth of damage.

-

03-12-2020, 08:09 PM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Make no mistake, there are a handful of people that do nice work with a dremel, but only a handful. The rest make a mess and then have to either fix it or hide it.

It's not what you know, it's who you take fishing!

-

03-12-2020, 10:58 PM #6Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,049

Thanked: 636

Tread lightly. It takes a micro second to destroy a blade. Catch an edge and crack of chip the blade. Fun it too fast and too long and burn the blade. Mirror finish is not all its cracked up to be. It took decades and sometimes a century of more to get a nice patina.

I remove dust with FOR and brass brush. Rinse thoroughly and start sanding. When it is where you want it then set sand with 2000 and up wet/dry sand paper and polish with Mothers.

-

03-12-2020, 11:57 PM #7

Try the Dremel on a blade that’s trash and see how it comes out. Like Shaun said, only a handful of people are good enough with one to do a good restore. I’ve tried and went right back to hand sanding. They work well, the problem for me is that I couldn’t keep an even surface which actually doubled the amount of time it should have taken doing it by hand.

I think it’s worth a shot, just practice on something you don’t care about.

-

03-13-2020, 12:00 AM #8

I've done numerous razors with the dremmel, but I prefer to do it all by hand.

You'll be better off being patient, and do it by hand. Even the polishing can be done by hand. You'll cherish your work for years to come, with great pride.

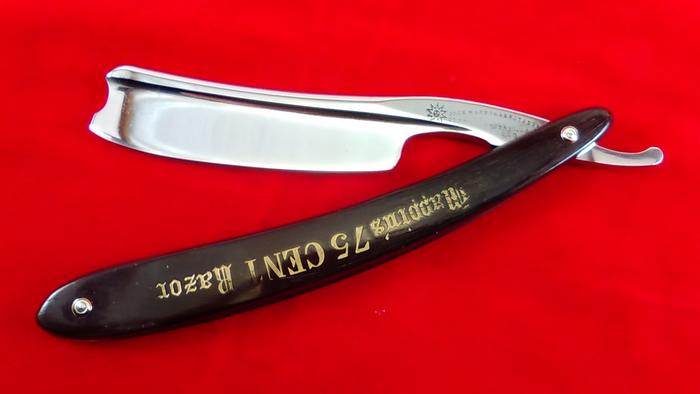

For instance.

Not a single power tool, used.Mike

-

03-13-2020, 03:16 AM #9

"With great power comes great responsibility." Using any power tool requires lots of practice and even then it is still a challenge. Scraping exess then metal polish and steel wool will go a long way to freshening a blade. 3k gives a fantastic finish. I don't think I would bother going much if any beyond that.

One major word of warning: search "foiling". In a nutshell you can become so intent on removing pits that you turn a perfectly good razor into foil in the process even by hand sanding. The Kung Fu of it is to know when to quit sanding and be happy with the result.Last edited by PaulFLUS; 03-13-2020 at 03:18 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-13-2020, 07:08 AM #10Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,389

Thanked: 3228

68Likes

68Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote