Results 1 to 10 of 13

Hybrid View

-

04-08-2018, 08:26 PM #1

Fixing a weird hole in old french scales

Fixing a weird hole in old french scales

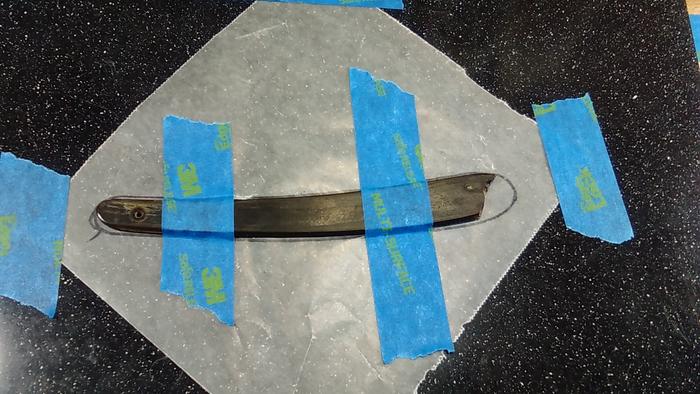

So i got this old razor for very cheap, the razor was all worn off from excessive honing and was basically dead, but the razor wasn't the point. It came on a very nice pair of an early french scales I wanted to use for an orphan early french razor.

The german razor was clearly not the original and obviously too short for them, so whoever owned it decided to make a custom spacer with a steel rod right above the bottom pivot..

Removing the razor and the spacer without causing any damage to the scales was one of the hardest removals I've ever done! Boy that steel rod was thick and tight but after putting a decent amount of time using a Dremel with a very thin disc I managed to remove the spacer with one small overheating damage to one of the holes (yes I have an jewelers saw and yes I wasn't thinking of it at that moment ).

).

Now I have a pair of good early scales but with two freaking holes in it. My first thought was using a silver steel rod and just make a flat pin on both sides, but I wasn't sure how "authentic" it would look. I've read that some members recommended using a horn dust to fill imperfections on scales but never really delve into it.

Would love to hear some thought or helpful tips on how I can decently repair it

-

The Following User Says Thank You to OrSh For This Useful Post:

Voidmonster (04-18-2018)

-

04-08-2018, 09:02 PM #2

I repaired some black horn using ebony dust and super glue. It seemed that when i used horn dust it came out grey.

-

04-08-2018, 09:52 PM #3Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

-

04-09-2018, 12:26 AM #4

-

04-09-2018, 10:54 AM #5

I've repaired black horn with bog Oak and epoxy, then a thin coat of CA over the top so it would polish up.

Mike

Mike

-

04-09-2018, 11:09 AM #6Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 640

Thanked: 104

wow Thats impressive. I cant even see where the chip was!

-

The Following User Says Thank You to MrZ For This Useful Post:

outback (04-09-2018)

-

04-09-2018, 11:10 AM #7Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 640

Thanked: 104

-

04-08-2018, 09:25 PM #8Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,018

Thanked: 631

I would put tape on flat side. Fill hole 1/2 way with Superglue and let dry. With fine tip marker color Superglue in hole. Top off with more Superglue. When dry, sand and polish. The black marker makes the repair look solid black and blends in with rest of scales.

-

04-09-2018, 03:58 PM #9

-

04-09-2018, 04:11 PM #10

18Likes

18Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote