Results 21 to 30 of 39

Threaded View

-

01-07-2023, 07:24 PM #1Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,817

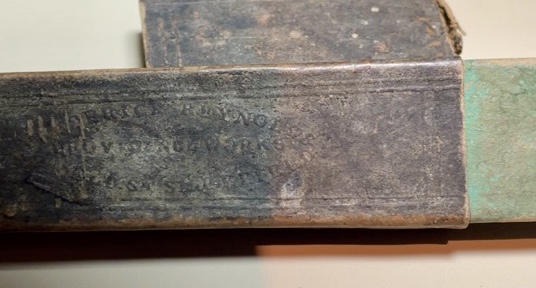

Thanked: 563 Frederick Reynolds - The Celebrated Hollow Ground

Frederick Reynolds - The Celebrated Hollow Ground

Just picked this up at a local antique store.

I will be cleaning it up and trying to restore the coffin box that came with it over the next while, so I thought I’d start this thread to keep me motivated and to solicit advice.

Normally, I would put the blade into new scales, but I’ve seen what Outback has done to renew old scales with bug bites, so I will try my hand at that for the first time.

David

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

100Likes

100Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote