Results 1 to 10 of 12

Thread: Centering Friodur

Threaded View

-

04-06-2010, 04:45 PM #1

Centering Friodur

Centering Friodur

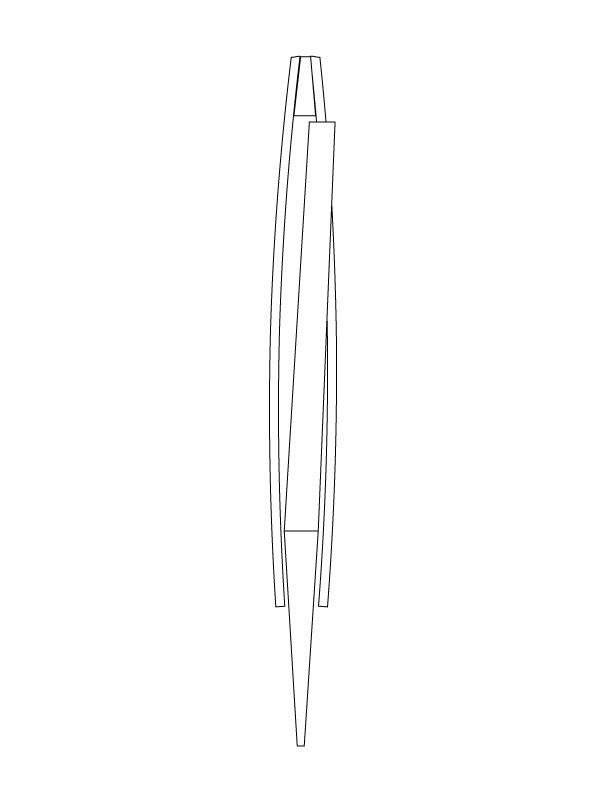

I hope this thread will eventually help everyone here, because I am having a hell of time getting a 8/8 Friodur to center. I have another one that is even worse. I have looked at the centering Wiki article and I just wanted to get a few more tips before having to unpin this one again. I made an exaggerated (slightly) image to show what is going on.

I already tried to pin it with 2 washers on the left side and one on the right. It centered on my test fit, but as I tightened the pivot it drifted to the right again.

Any help would be appreciate by myself and all that have rescaled Friodurs.

Thanks!

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote