Results 1 to 9 of 9

Thread: small contact wheels

Hybrid View

-

04-30-2011, 06:15 PM #1

small contact wheels

small contact wheels

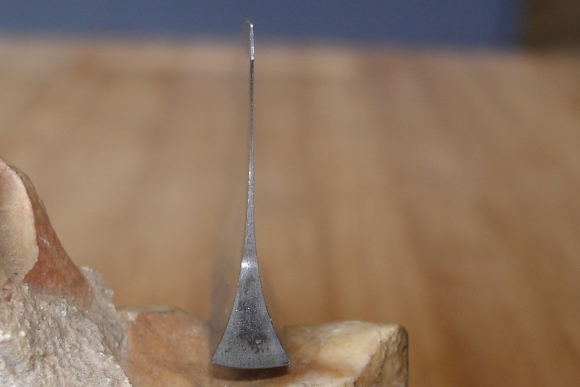

I played around with the 1" contact wheel this morning, I like the hollow it makes it under the spine. I have been using a 2" or 4" wheel for this part of the grind. I used a 2" and a 1" on the razor in the picture.

I have always admired Butch's and Bob Allman's hollow grinding - they inspire me.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

dirtychrome (04-30-2011)

-

04-30-2011, 06:44 PM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I love your double wheel set-up. It's definitely what I want to build (or buy from you) when I grow up!

I'm confused where the 1" and 2" wheels were used though. Did you use them on opposite sides of the blade?

-

04-30-2011, 07:28 PM #3

I do not use the double wheel grinder very often, it is a good roughing tool, but a poor finishing tool.

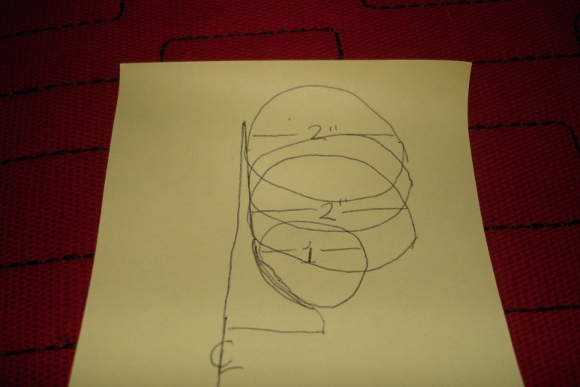

I ground the same on both sides of the razor. I started the at the edge with a 2" them mad a sieres of grooves working my way back to the spine. Then blend the grooves together to make a flat surface.

Here is my CAD drawing (Charlie assisted doodle)

Charlie

-

The Following 3 Users Say Thank You to spazola For This Useful Post:

dirtychrome (04-30-2011), ScottGoodman (04-30-2011), Utopian (04-30-2011)

-

04-30-2011, 07:43 PM #4illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Thanks, that clears it up. I couldn't see a belly or any way to see the two different wheels' concavities. I had no idea anyone "blended" the way you described. (By the way, your CAD is the only way I can do it!) What is your rationale for not leaving a belly?

-

04-30-2011, 08:44 PM #5

-

04-30-2011, 11:42 PM #6illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

There is definitely a cool factor. If I were to ever do this, I'd fully expect to grind holes all the way through quite a few razors.

Nice job!

Maybe I can talk Randy into a Texas road trip some time!

-

04-30-2011, 11:47 PM #7

Great looking grind Charlie!

I've played with a similar set up but tend to alu-foil it about at 1/4'ish from the edge.

Ah...one day I'll make it work.

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote