Results 1 to 10 of 28

Hybrid View

-

09-12-2012, 01:58 AM #1Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209 New Tapered / threaded mandrel for sanding and buffing razors

New Tapered / threaded mandrel for sanding and buffing razors

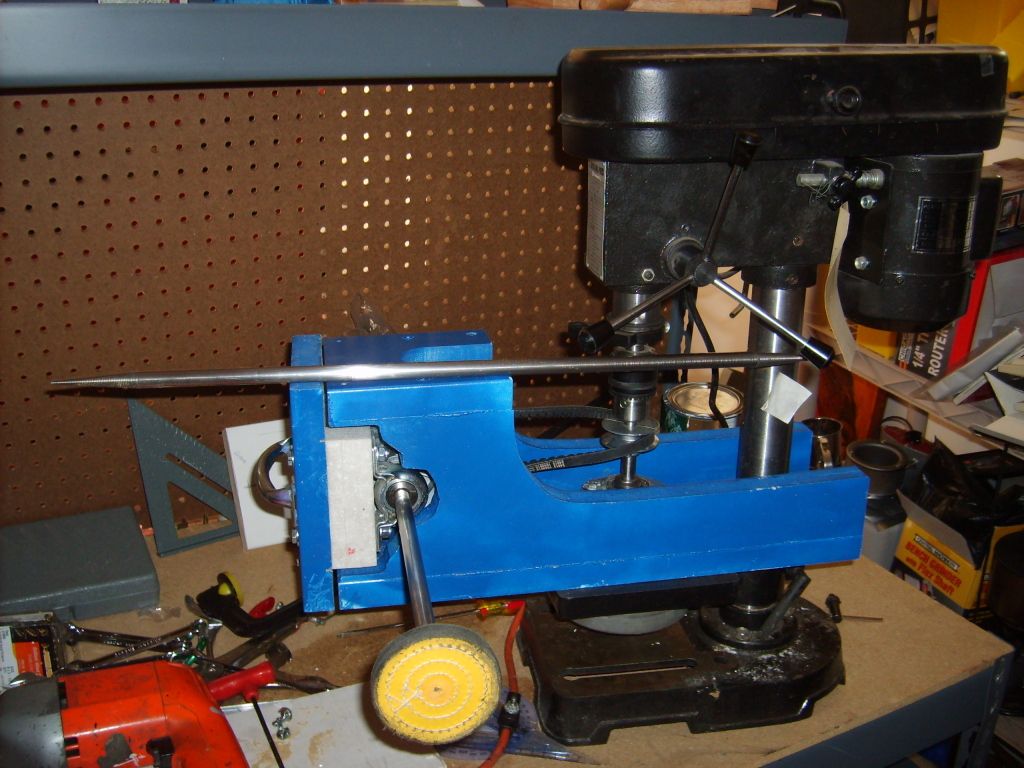

Here are some work in progress pics of a new sander/buffer I am assembling using a 1/2" diameter stainless steel tapered & threaded mandrel, 24 : long, that our guy Geezer has made. His intent was to make a mandrel that did not require a separate set of cones on the end of a shaft. This is my first implementation of the sander/buffer and I am using an old arbor setup that I had saved. The clearance on each end is about 8.5 ". Since I will be running it at about 1000 rpm max I expect no wobble. Tomorrow I will be installing the arbor on a table & connecting it to a motor. More pics to follow.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

-

09-12-2012, 02:00 AM #2

Very cool!

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

Geezer (09-12-2012)

-

09-12-2012, 02:07 AM #3Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

-

09-12-2012, 02:12 AM #4

Thanks Charlie,

Your solution is a winner for any long shaft!

For those who didn't see it yet here is a link to the grinder/polisher that Randy pointed out to me when he heard what I was doing.

http://straightrazorpalace.com/forge/87222-building-new-grinder.html

~Richard

-

09-12-2012, 02:19 AM #5Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Oh, and here is the arbor before I cleaned it up and before Geezer helped me by getting it assembled correctly...........

Last edited by randydance062449; 09-12-2012 at 02:37 AM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

09-12-2012, 03:04 AM #6Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Cool, Randy. I'm rebuilding an old pulley driven grinder to use as a buffer. 1/4 hp/1750rpm, and about 3 inches of clearance. Not as long as yours, but it should work a lot better than my 2 speed grinder. Pics on request.

-

09-12-2012, 03:34 AM #7Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209 Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

09-22-2012, 02:23 AM #8

The other guys are doing theirs also; expect some photo posts soon from them too. They have come up with differing ideas for their own spaces and usage. They stay in touch and ask questions that get me thinking!!

For my first trial:

Not much for looks; it does the job and is reversible when required. It made usable "cheap" prototype and I learned a lot. I got a few better ideas for the next one/s.

Have fun!

~RichardLast edited by Geezer; 09-22-2012 at 02:27 AM.

-

The Following User Says Thank You to Geezer For This Useful Post:

spazola (09-22-2012)

-

09-12-2012, 02:00 AM #9Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

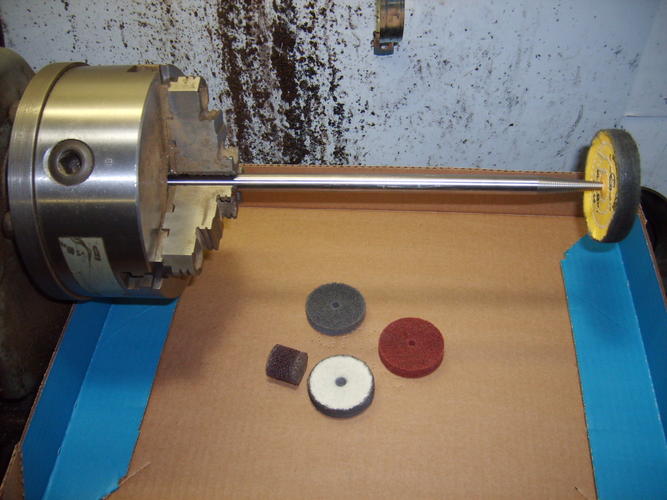

Here are some pics from Geezer to give another idea of using it in a lathe.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

09-12-2012, 02:01 AM #10

Looks great Randy, thanks for the pics. I can't wait to see it all setup.

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote