Results 71 to 77 of 77

Threaded View

-

08-12-2008, 07:55 PM #1

My GDLP has issues...........................

My GDLP has issues...........................

As the title suggests, I want to stress that MY GDLP has issues; I have no reason to think or certainly no information to support any assertion that ALL GDLP's have the issues I'll describe here. I'm in the process of dealing with Harrelson Stanley, U.S. distributor for Shapton. My GDLP as of today is being Priority mailed back to Harrelson. I'm looking for an exchange, refund or a potential upgrade to the DRLP (unlikely that I'd want to pay the difference to upgrade to this even if Harrelson would offer this as an option).

In summary, my GDLP after using it lightly for just under six months has degraded in performance dramatically. What used to take a few minutes in re-lapping my Shapton Ceramic on Glass stones now takes upwards of 15 minutes or more.

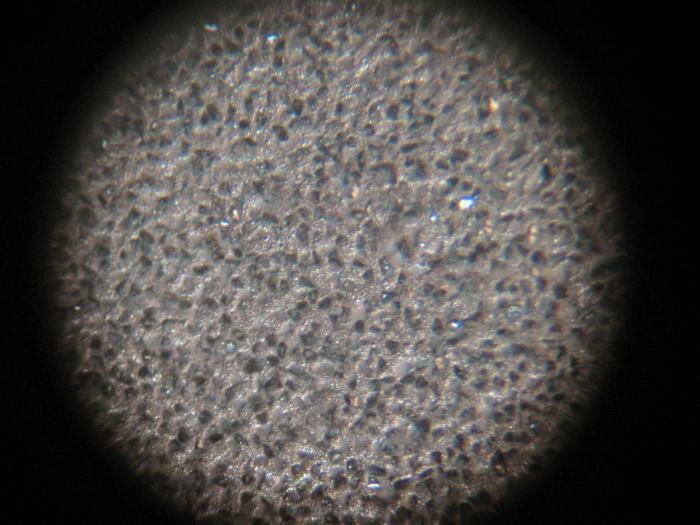

Sadly, viewing the surface of the GDLP under 40x magnification appears to reveal the reason for the performance degradation. Approx 80% loss of diamonds. That's huge. Here are some pictures that have been emailed to Harrelson:

This first picture is a close up of one of the edges of the GDLP taken last week. The edges of the GDLP remain very sound; In addition to lapping my Shapton ceramic stones on the GDLP, I also lap my small number of Coticules, Thuringians, Belgian Blues and an occasional barber hone. These stones are all smaller than the Shapton plates and the middle of the GDLP has seen more use than the edges. I would expect a small loss of diamonds in the center vs. the edges then, based on my usage.

This next pic is a picture of the center of the GDLP. Almost no diamonds left. You see the occasional black fleck (diamond) and the nickel substrate.

Bummer. I viewed each picture on my screen and drew an imaginary line straight across each picture. Then I did a non-scientific count of the diamonds that the "line" ran across from left to right. I then divided out the numbers and came up with the approximated loss of diamonds in the 80% range if that makes sense.

I debated on posting this until AFTER this issue was brought to whatever resolution it will come to, but after talking with another longtime SRP member, he suggested I post my issues now.

I lap as directed by the Shapton website (basically back and forth with some diagonals thrown in) and, I lap lightly. I do NOT use excessive force or even use force when lapping. I keep the stones on the GDLP and try to let the diamonds do the work. I know how to lap.

Here's what I've found out from Harrelson that I did NOT know about the GDLP:

- The GDLP's diamonds bonded to the nickel substrate are actually found in several layers. More than one "coat" of diamonds and nickel. I believe this since when I view the surface of the GDLP under magnification, I can barely see the tips of diamonds barely peaking out from the nickel surface; some are almost completely covered by the nickel and therefore have no effect when lapping.

- Sometimes hardened slurry can coat the diamonds reducing performance. Soaking the GDLP in water overnight is recommended to soften the slurry then.....................the following is recommended much to my surprise:

- A Shapton Lapping Disc for $19.95 is recommended to actually lap the surface of the GDLP, nickel, diamonds and all! Harrelson explained that the ceramic disc is extremely coarse and removes metal and the diamonds. The idea here is that by lapping the GDLP's surface, you are able to expose the unused diamonds encased in a lower layer of nickel. Essentially hopefully refreshing the GDLP's surface.

I have issues with this and would NOT be comfortable lapping the GDLP surface. It's not even the principal of having to buy an additional accessory, it's the fact that if I manually lap GDLP's surface, IMO I can kiss the .5 micron flatness goodbye. By how much? Who knows?

I did not post this to discourage anyone from buying a GDLP and my greatest hope is that I got one that was defective and was an anomaly. Still I wanted to make you guys aware of this and also ask if others with GDLPs have had any issues even close to what I describe (basically a noticeable degradation in performance).

I've followed the instructions that came with the GDLP in that I have never lapped any stone coarser than the Shapton 500 grit stone. The instructions make reference several times to the fact that the GDLP was created to lap the Shapton Ceramic on Glass stones but nowhere in the instructions does it mention that lapping any other TYPE of stone is prohibited.

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

The Following 7 Users Say Thank You to ChrisL For This Useful Post:

gssixgun (08-12-2008), icedog (08-13-2008), Philadelph (08-12-2008), randydance062449 (08-13-2008), Russel Baldridge (08-12-2008), sigman (12-25-2009), str8razor (10-02-2008)

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote