Results 1 to 10 of 77

Threaded View

-

09-15-2008, 03:57 AM #15

OK guys........HERE'S THE VERDICT.

OK guys........HERE'S THE VERDICT.

I received my Harrelson Stanley inspected and Harrelson Stanley lapped GDLP a few days ago. I was impressed by the speed in which he returned the stone to me by priority mail with my original GDLP box also returned intact (I keep boxes of razor related things I buy, what can I say?).

The first thing I did is take the GDLP down to my stereo microscope for some close up viewing. That 120 grit Shapton ceramic disc he used to lap the GDLP does dig into the nickel substrate.

I thought it best to post the original close up pictures I took at the start of this thread side by side with the pictures I took since receiving my lapped GDLP back. Here goes:

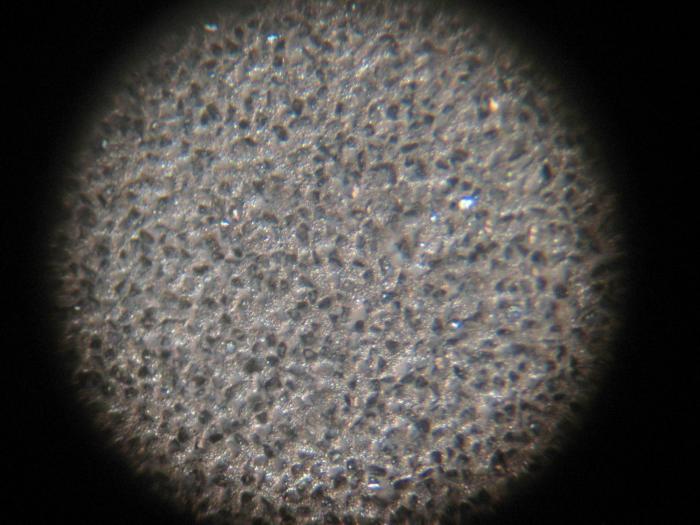

ORIGINAL CLOSE UP PICTURE OF ONE OF THE SURFACES OF THE EDGES OF MY GDLP PRIOR TO SENDING IT BACK TO HARRELSON

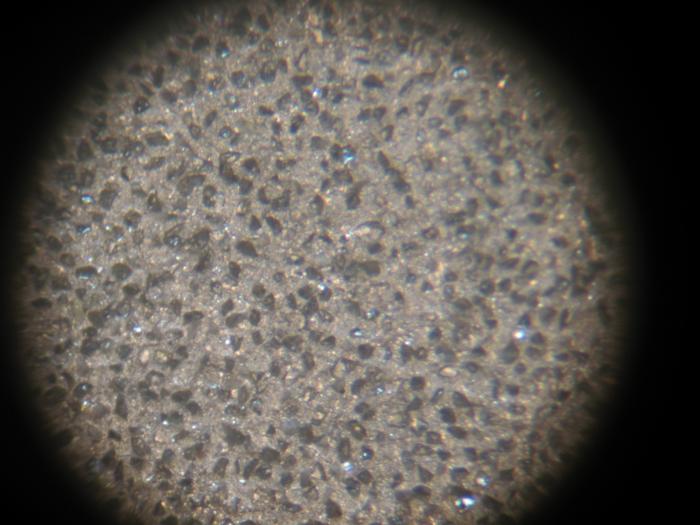

EDGE PIC CLOSE UP AFTER RECEIVING BACK FROM HARRELSON

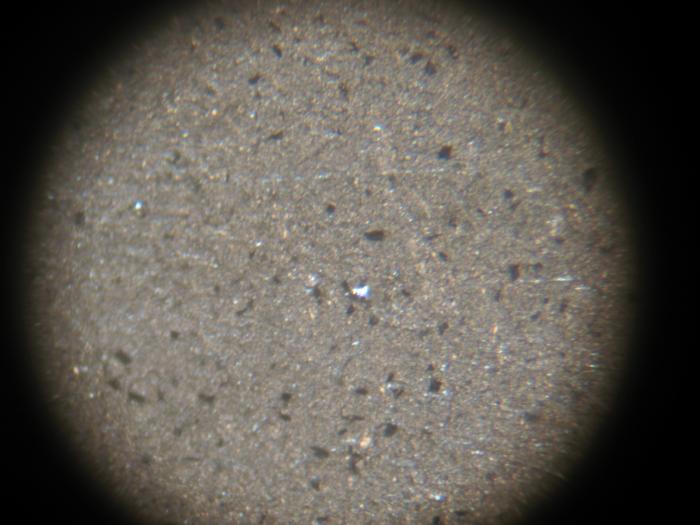

ORIGINAL GDLP CLOSE UP PICTURE OF A RANDOM AREA OF THE MIDDLE SURFACE

MIDDLE SURFACE AREA PICTURE AFTER RECEIVING BACK FROM HARRELSON

I see no significant visible change to the surface before to after. The diamonds are black or shiny flecks as seen under light while any area that is dull mottled gray is the nickel substrate.

That's the visual. To be fair and comment on what really counts......how does the GDLP perform now vs. then? I only lapped my Shapton ceramic on glass stones since receiving the GDLP back from Harrelson. These are all stones that have previously been lapped flat by the GDLP and have not been lapped with any other type of lapping plate. I lapped my 500, 1k, 2k, 4k, 6k, 8k & 16K. Remember, these all only needed refreshing. From start to finish, it took me 1/2 hour. Part of me feels or maybe wants to feel that the performance has improved a little. But I can honestly say there has been no dramatic, significant or even unquestionably obvious increase in performance.

I did not lap any of my stones using any more force than I have in the past. In no way did I "put my shoulders into it" like Harrelson described the way he laps with GDLPs. Back and forth, back and forth with a few diagonals just as seen on the Shapton website.

My conclusion; I think I personally got a bum plate. Since I'm the only one who's reported such issues out of all of us, I'm comforted in such a conclusion. I'll be mailing the GDLP back to Harrelson, taking him up on his offer to refund my money/return shipping. I don't know at this point what I'll do from here regarding lapping my Shaptons.

I do have a DMT D8C, D8F, D8E on the way from Craftsman Studio arriving on Wednesday. I placed this order before I received the GDLP back. Why? I'm getting into sharpening chisels and plane irons more now, and I have a fair amount of barber hones that I've amassed. I want some lapping plates that I can work to hog steel and barber hones and not worry about if/when they degrade. To test my conclusion regarding the GDLP, I may very well purchase another one in the future. Only time will tell.

All in all, I don't discourage anyone from buying a GDLP. With its recessed surface areas and design, it's a pleasure to lap stones with it. IF....the issue I've had is more widespread (I don't think it is), then it would undoubtedly come to light.

Harrelson and Shapton are branching out and broadening the supply chain for Shapton products. In branching out, part of what he may have stepped into is a user group (razor nuts) different than working woodcraftsmen, production shops, etc. If I was a tradesman using the GDLP as a tool for my craft, I could also see myself leaning hard on the GDLP to get the lapping done and get back to woodworking fast. I could see myself applying more and more pressure until I eventually wore out the plate, then I'd buy another one and not think much about it.

We're hobbyists where the GDLP is at a much higher price point than other plates we can use. I and I think most of us take great care of our razor related tools; baby them really. Owning this for less than six months, using it very little compared to a working woodcrafter and having such a decline in performance means I think I look at my issue differently than I would otherwise. Chalk it up to a fluke plate is what I say.

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

The Following User Says Thank You to ChrisL For This Useful Post:

Philadelph (09-16-2008)

1Likes

1Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote