Results 11 to 20 of 109

Thread: Why lapping film rules

Threaded View

-

02-20-2009, 02:51 PM #1< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735 Why lapping film rules

Why lapping film rules

OK, so why is lapping film any better than a hone?

Flexibility.

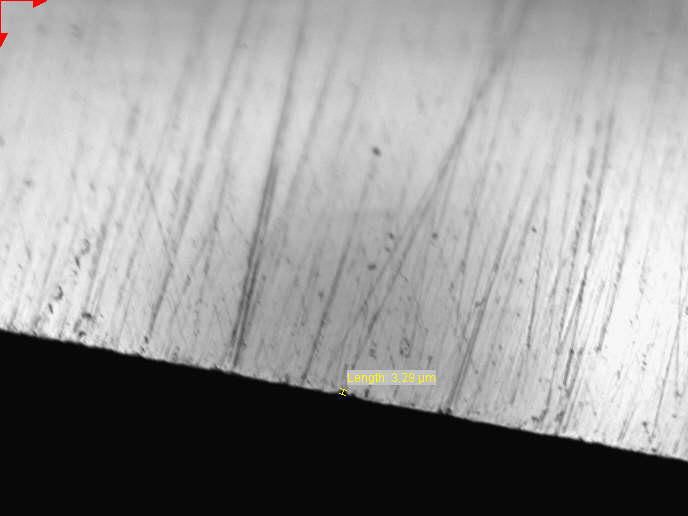

Here is the edge coming off of the 0.3um aluminum oxide film, laid flat on the precision granite plate:

Not bad (I did not spend a whole lot of time on that edge...)

But then I put the magic of lapping film to work---I put a single sheet of plain paper under the lapping film, which adds some cushion, and give it a few passes....

Much better!

I've played around with mulitiple sheets under there, which leads to a stronger convexing of the edge, but a single sheet on the finishing grit seems to give the best results.

Viva la Film!

-

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote