Results 1 to 6 of 6

Thread: 0.25 micron diamond spray SEM

Threaded View

-

06-14-2013, 08:22 PM #1member emeritus

- Join Date

- Dec 2012

- Posts

- 112

Thanked: 62 0.25 micron diamond spray SEM

0.25 micron diamond spray SEM

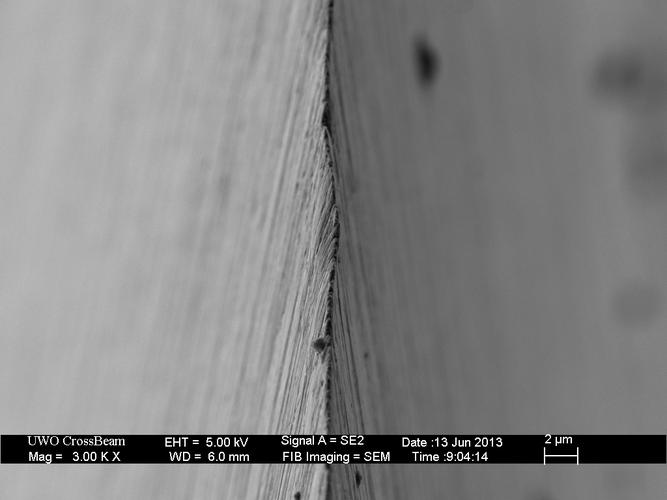

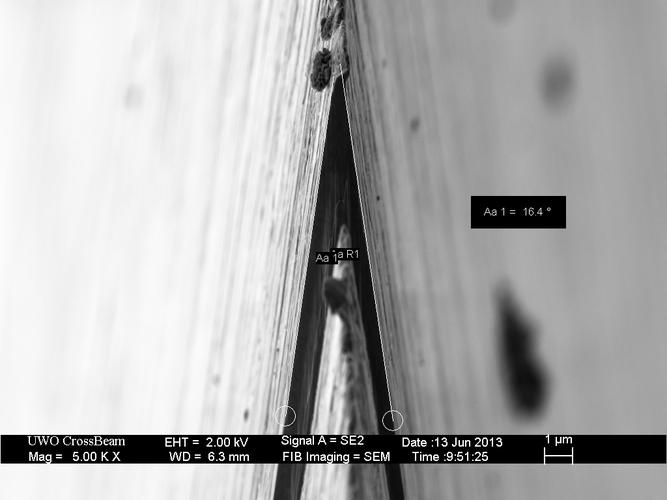

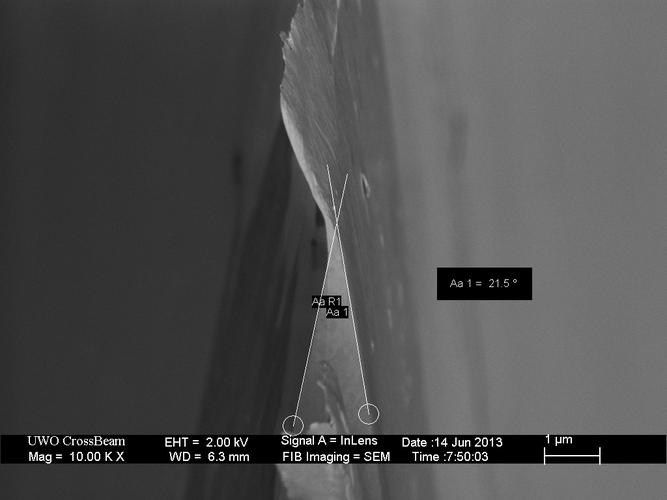

Following a Shapton 8k edge - A perfectly triangular bevel with 16.5 degree angle, as expected from the blade dimensions. Edge width is around 200nm.

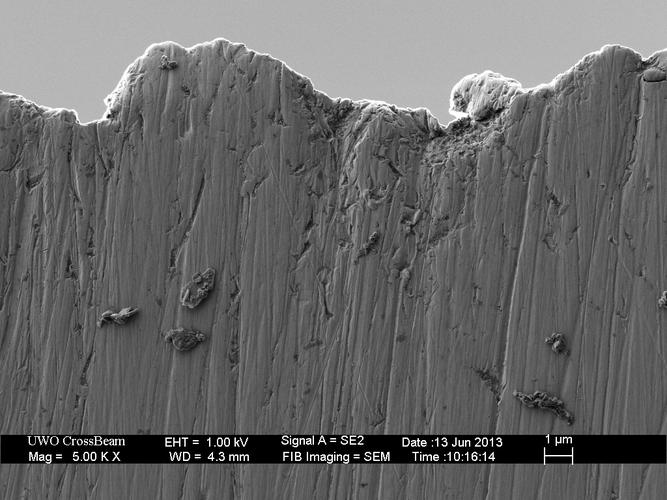

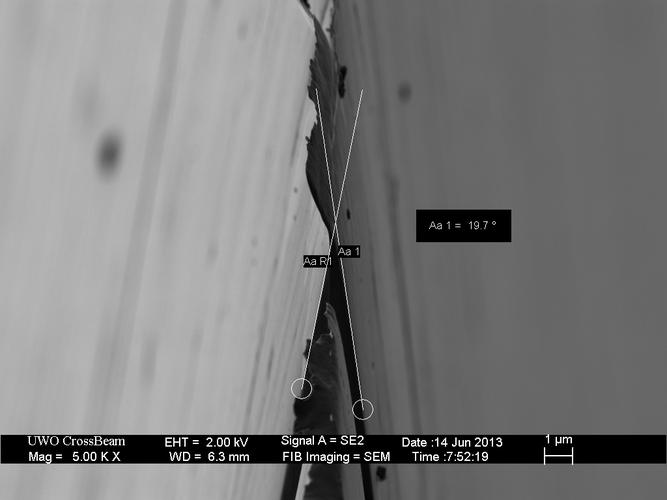

10 laps on a 2" wide English bridle strop with 0.25 micron diamond spray over about an 8 inch length.

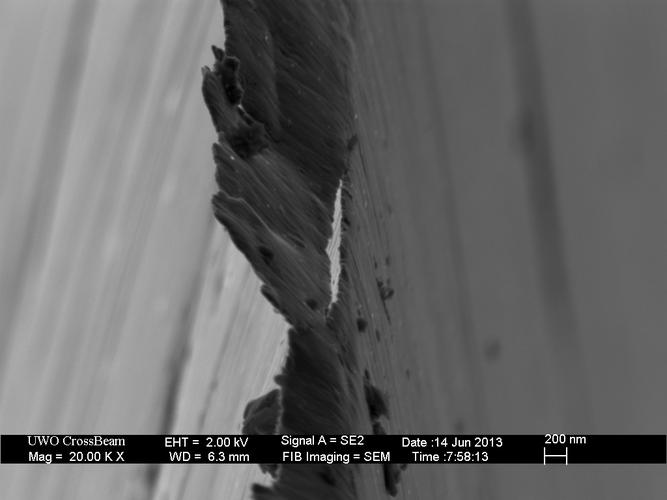

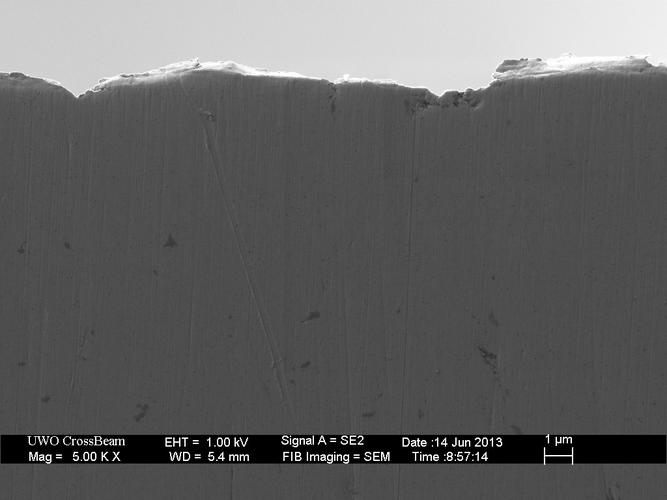

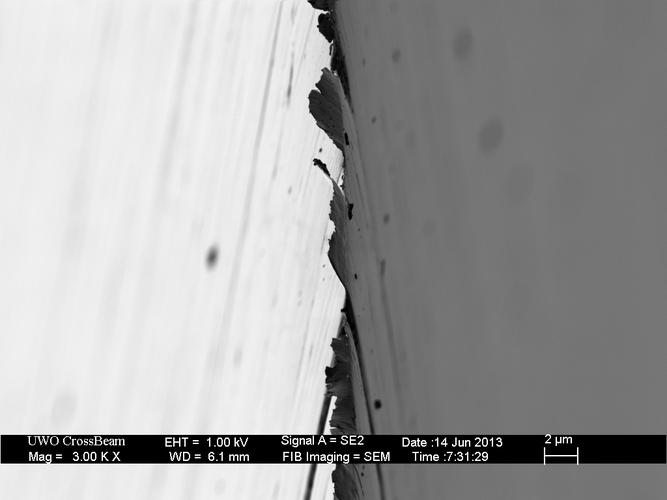

The last 10 microns of the bevel are convexed (or micro-convex) and a foil edge is formed. Where the foil is broken away, the edge width is less than 100nm.

-

The Following 13 Users Say Thank You to fuzzychops For This Useful Post:

Bram (11-20-2014), criswilson10 (08-03-2014), FacialDirt (08-02-2014), Kefka (01-26-2014), Lemur (06-14-2013), MT4 (11-14-2014), Neil Miller (08-02-2014), PhatMan (06-15-2013), Sterm (06-14-2013), Thunderbird (06-15-2013), Vasilis (01-20-2014), vmspb (02-21-2017), WadePatton (01-26-2014)

17Likes

17Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote