Results 1 to 10 of 18

Thread: A few hesitant questions

-

12-12-2014, 02:28 PM #1Junior Member

- Join Date

- Nov 2014

- Location

- Fort Wayne, IN

- Posts

- 8

Thanked: 0 A few hesitant questions

A few hesitant questions

I'm new to this, but same as most, have spent 20 or 30+ shameful (but necessary) hours reading posts and watching Lynn's youtube videos.

Purchased an old blade from an antique store that had almost no nicks. The King Razor Mfg. (King Special) branding on the scales threw me off, but the blade was a Baurmann and Sohne, which from what I've read, is a respectable steel to start on. Figaro 42, I believe. Sadly, it'd been broken at the bottom three eighths inch of the heel, but otherwise despite some black corrosion, no rust, it was alright.

I purchased a Norton 220/1k and 4k/8k from the same seller on ebay that had been a barber. After the first honing session it was only slightly duller than before. I did mostly all 1k with almost no pressure at all, which I found was a mistake after watching and reading more of Lynn's material, since little to no metal was coming off.

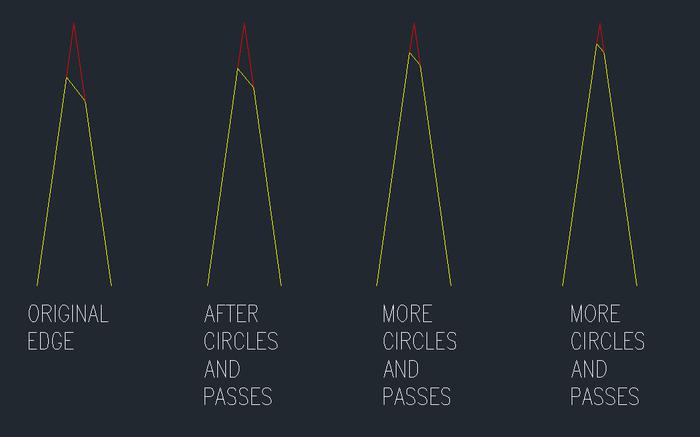

I then decided the stones needed lapping (which they apparently did). After using a sharpie I realized I had an uneven bevel from whoever owned the razor before me. I got out my pocket microscope (used to take the 3rd picture below) and saw the uneven bevel and upon more honing and eventually using the 220 sparinly got the bevel even as seen below.

Bevel progression as honing progressed.

http://i.imgur.com/4z7N3Ot.png

I did a shave test after the 2nd honing (and stropping) and was surprised by how much difference I'd made, but it still wasn't close, was pulling, and didn't pass the HHT, in short, was nowhere near shave ready.

I did another of Lynn's pyramids, with more pressure this time and again was very impressed with how much difference there was. I actually shaved everything, chin, neck, and all on my 2nd shaving (5 days of growth since last Sat when I first tried). Still, it wasn't where it should be, as can be expected since I'm new to this. (3rd honing try, 2nd shaving try). Think nice electric razor closeness, ha, not painful but certainly not DFS.

So I'll continue trying to improve it but in the mean time, I've found one person in Fort Wayne, IN based on his profile. That is Trox, but he's been silent on SRP for about a year now to the day. Is there anybody else on here in Ft Wayne, that could maybe help further cut my learning curve down? (no pun intended)

Last question, I noticed the top 2/3 of my blade is sharper and with magnification is overall much better than the bottom 1/3. Would that be because I have a slight curve (not quite smiling, I'd say, see 2nd picture) or probably because I'm applying too much pressure at the 1k towards the top of the blade. (Water follows the edge well throughout all my circles and X strokes, so I don't know)

Thanks for the help, you guys are great, I'm pretty stoked to be in this. Last night's shave while not perfect felt like a promising first date with straight razor shaving.

Significantly cleaned up, and further cleaned after this was taken.

http://i.imgur.com/4Pu3Nwo.jpg?1 (high res)

Edge closeup (roughly 6-10x magnification)

http://i.imgur.com/bDwcklE.jpg?1 (high res)

Just kidding, real last question as an afterthought. I see Lynn do a TPT often. If I can shave (albeit not perfectly) shouldn't I feel my razor biting into my warm wetted thumb pad, becuase I don't. I'm also not pressing hard. Any articles I failed to find about TPT's? I think I'm just not doing it correctly. Thanks again.Last edited by mrmessma; 12-12-2014 at 02:33 PM.

-

12-12-2014, 02:49 PM #2

The razor has wear from honing with no tape over the years. That is likely causing you issues in trying to get the edge even and a bevel set. After you have honed a lot you will be able to maybe save this one but for now find a better candidate for a razor. I suggest a shave ready razor until you have shaved a good while. As far as someone in Ft wayne, that would be a big help. I lived there for over 50 years and still have sons and other family there but now live in Idaho. If my old barber Ed from Ed;s barber shop on broaway & taylor was still alive, I would have him help. Sadly he has been gone a while now. Someone will come forward. A good mentor is a big plus. The thumb thing - just drag your thumb slowly across the blade. The blade should catch the thumb

One tired old Marine- semper fi, god bless all vets

-

The Following User Says Thank You to cubancigar2000 For This Useful Post:

mrmessma (12-12-2014)

-

12-12-2014, 03:47 PM #3

mrmessma,

If I may suggest, junk that razor and start afresh with a serviceable new production or vintage razor that is shave ready. Start on the right foot. Also, put aside honing for now and concentrate on honing your skill with the straight razor and the strop. There is plenty of time for honing. By the way, welcome to Straight Razor Place.

-

12-12-2014, 04:33 PM #4

First off , You are doing great, you are actually ahead of the curve right now.

1 The uneven bevel. Do 20 or so circles on the HIGH side to bring it more in line with the low side. Check and repeat as needed.

2 As of right now, Glen has stated in his videos that ALOT of blades never had the heel hone in.

Meaning bevel set through finish.

He speaks on feeling it and working just that area of interest with increased pressure and circles would speed up that process.(Heel only area)

3 After addressing the first 2 issues you will want to blend/smooth out the work on both ends. This should be easy after all that you have done thus far.

20 circles and yada yada x strokes on your finishing stone. You should be close to dialed it.

Try the above suggestion. Problems ,Issues and success?? ASK thats what we are here for,

We want to help.Your only as good as your last hone job.

-

12-12-2014, 04:40 PM #5

I had the WORST time understanding/grasping that TPT. I call it the jackknife test. you know how you test a pocket knife? Exact same thing put just enough downward pressure till it catches/pull on your thumb. Lick your thumb and it gets slippery so you feel tinglies before it catches/pull . All the is done ACROSS the blade just like a pocketknife. It should feel like your sharpest pocket knife. If it does you just passed the TPT.

As far as hours in the library, I got 100 hours more than you, found a Mentor . I still am in the library nightly.

Rereading, missed something.... Look at my join date, just because it says Senior dont mean diddly if you dont do your time in the books. The Big boys (look at join date&posts) Have been answering that exact same question so many times that it can become mind numbing. They will and want to help. Showing that you looked up info, tried, and pictures include with your question speaks volumes in your favor.

Now I have to go back to the Library.Last edited by ultrasoundguy2003; 12-12-2014 at 04:52 PM.

Your only as good as your last hone job.

-

12-12-2014, 06:03 PM #6

Welcome mrmessma to SRP: You're making fantastic progress. It's nice to see new members read and learn on their own. So many folks just post on the forum without taking the time to research. Just a couple of questions. Did you add a piece of electrical tape to the spine of your razor? Is your razor cutting arm hair easily on your bevel setting stone. Don't move to the next stone in your progression until your easily shaving arm hair off your 1K grit stone.

Once you can easily cut arm hair off all sections of your edge, it's just a matter of polishing out the scratch marks as you go down your stone progression. If you started off with one piece of electrical type on the spine add two more when you get to your highest grit stone. Adding two extra layers of type is the method used by custom knife and razor artisan Tim Zowada. http://straightrazorpalace.com/honin...edge-tape.html

Last edited by feltspanky; 12-12-2014 at 07:21 PM.

-

12-12-2014, 06:36 PM #7Junior Member

- Join Date

- Nov 2014

- Location

- Fort Wayne, IN

- Posts

- 8

Thanked: 0

I could cut armhair easily off the 1k. By 8k it was cutting hair off above skin level, but not easily.

I wasn't using electrical tape, as from what I'd understood it was for aesthetic preferences, of which this piece I'm not concerned. I figured for as thick as the spine is, you'll never take an appreciable enough amount off to truly screw up the geometry without first removing all the metal from the blade itself (since it's a half (or full) hollow I believe). Should I tape the blade to further reduce spine wear, regardless? I don't believe that a whole lot more metal needs removed to set the bevel/remove nicks (of the 1/3 near the heel), so I believe the spine is alright.

I will see what a few more people think, but right now I think working the heel area makes sense.

I don't want to junk the blade (since I'm stubborn and bought it, albeit cheaply) and want to eventually get it functional, even if that is farther down the road. Also, based on the progress I've made, I don't think I'm doing the razor any disfavors. On top of that, SRD is nearly out of every Dovo under $200. Any other reasonable suggestions from the "junk it" crowd and get a pro honed benchmark so I know exactly what I'm shooting for?

Again, thanks for the input whether it's what I want to hear or not.

-

12-12-2014, 06:46 PM #8

The electrical tape is not only used for aesthetic purposes. It also increases the angle of the spine on the razor. It changes the angle of the edge making contact with your stone. Why not add a few layers of tape, make twelve honing laps with only the weight of the razor pressed onto the stone. Use your magnification to see if your edge looks different. Maybe lather and try a shave.

Last edited by feltspanky; 12-12-2014 at 11:18 PM.

-

12-12-2014, 07:50 PM #9At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,161

- Blog Entries

- 1

Thanked: 13249

Something to understand about this particular razor...

It has been "Fixed" it had a cracked heel, it was ground out, doesn't mean it can't shave but it does mean that it is particularly susceptible to pressure while honing..

That blade will flex very easily because of the fix. so it is slightly more difficult to hone from the get go..

If you are close as you say, then add 2 layers of electrical tape and do about 20 light laps on the 8k strop and shave, this will tell you where you are really at...this will concentrate the finish to the very edge...

PS; if the razor shaves this doesn't mean you're done, it just means you are on the right track and you are very close.. see if it works and then decide whether you want to proceed using tape, or if you want to back track and try making the entire bevel meet evenly..Last edited by gssixgun; 12-12-2014 at 07:54 PM.

-

12-12-2014, 08:03 PM #10

So you decided to start with a tough blade?

I would suggest getting a pro honed razor to compare it to. Whippeddog.com has sight unseen razors for $45 - it might not be a pretty one, but it will be honed and ready to shave with.

The electrical tape is not only for aesthetic value. It will help keep the blade angle correct while honing and keep the bevel width smaller down the length of the blade. In your razor's case, a layer or two or more of electrical tape will act as a fill in for the missing metal and bring the bevel angle back up to 17 degrees. Which will also mean less metal removal and less time on the hones. Change the tape as it wears and between hone grits so that you don't contaminate your hones.

It is possible that the temper on the heel was messed up when it was shortened. So it may be hard to maintain a sharp edge on that are. Or it could fine and just need more work.

It looks like you are proceeding down the right path with magnification and test shaves. Take your time with it and get the bevel straight and even. When you get frustrated, walk away from it for a little while and come back to it later. It takes patience to get a banged up blade like that back to shaving properly.

And the library is a black hone. Every time I refer to it to get a "quick" answer I end up seeing something new and losing a few hours to reading and learning.Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote