Results 1 to 10 of 12

-

01-02-2017, 08:10 AM #1

Possible solution to difficult situation in honing

Possible solution to difficult situation in honing

Hi

Many forums have threads that say "I'm trying to hone but nothing works. The razor just

won't become sharp" or such where beginners have do everything according to guides but still

the razor is dull. I had a similar situation. A razor that has a mirror edge that's dull and i

actually could pull a arm hair with its root when the hair was over the razors edge. The hair

was bent but not cut.

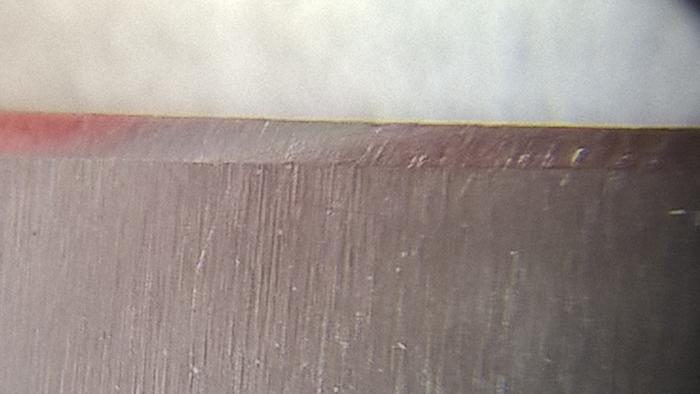

Here's a photo

It's a razor edge honed with 400 grit, 3000 grit and few minutes with 10.000 grit.

It has a shiny mirror edge. The blade looks bent but actually it's light playing around

with the polished edge. But so dull.

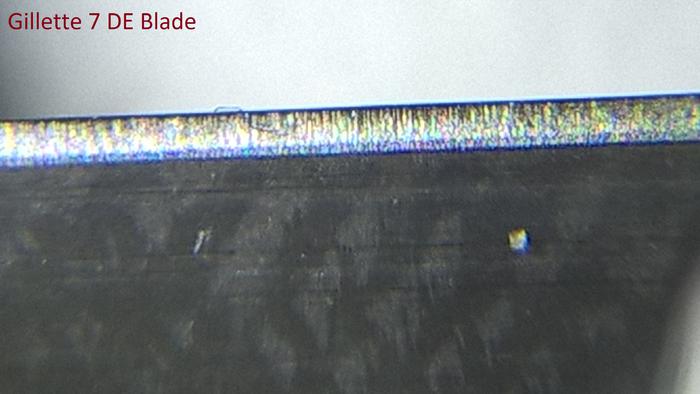

Then. I took a photo from a DE blade

The difference was that the actual tip of the razor has a "cutting edge" or how

should it be described. Think that's the part that does the cutting as opposed to a single form

bevel that's does not have a separate "knife edge" on tip.

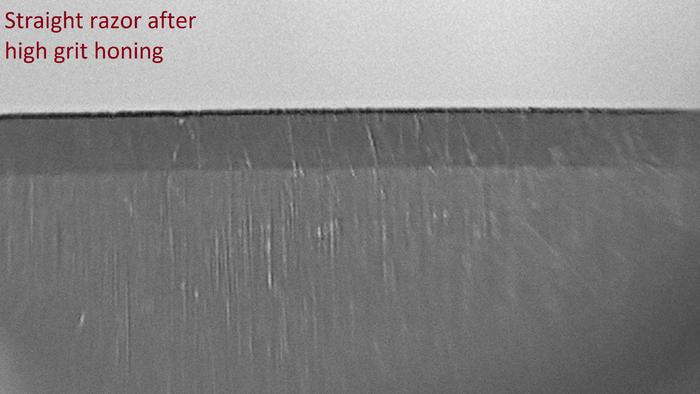

So next, about 400 laps with 10.000 grit stone

And same kind of "knife edge" appeared to the razor. I'm quite sure this is not a double bevel

resulting from honing with and without tape because i had that issue. It was resolved with

resetting bevel with low grit honing.

So now i tested with putting shave cream on small part of arm hair and the straight razor shaved the area

completely hairless.

So my theory is that when a razor is "properly" honed but mysteriously dull the reason MAY be that

the "knife edge" on top of bevel is missing. I assume that the knife edge is necessary because DE blades

have them.

-

01-02-2017, 08:35 AM #2

In the first pic, the bevel is not set. Watching some of gssixguns honing vids will help you get the bevel set.

400 laps on any stone is a lot. As I put your first post, get with someone near you for some hands on help.

http://straightrazorpalace.com/memberlist.php?do=searchIf you don't care where you are, you are not lost.

-

01-02-2017, 09:17 AM #3

Two things. 1.: you don't mention stropping before testing the edge. Many beginners ruin the edge with poor stropping technique. Moreover: you need to strop before testing the edge. You shouldn't test the edge straight off the hone. The cutting edge only reaches its full potential after proper stropping.

2.: a few minutes or 400 laps on the 10K is enough to create a wire edge.

And yes: as rolodave says: the bevel in pic 1 needs some more work.Last edited by Kees; 01-02-2017 at 09:19 AM.

Plus ça change, plus c'est la même chose. Jean-Baptiste Alphonse Karr.

-

01-02-2017, 10:52 AM #4

I did strop for 25 laps before testing.

So my mystery "knife edge" is actually a wire edge.

Back to the drawing board, then.

-

01-02-2017, 11:03 AM #5

yes 400 laps is a lot esp as you are new to honing (ie maybe not all of the 400 laps where good laps, a couple of duff passes here and there would be counter productive for sure, as is the jump from 3k-10k stone thats a big jump for sure,)

Do you have a Jewellers loupe?? they are cheap and very quick to use to check the edge while honing.

Where are you in the UK?

I am Merseyside based, if you are local or want to travel you are welcome to come over for some pointers etc.....

-

01-02-2017, 12:28 PM #6Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,382

Thanked: 3228

You can watch all the vids on honing you want and think you are doing it right but the reality is you are not. Plain and simple, your bevel is not set as in the 2 planes of the bevel have not meet to form an edge. Without a proper bevel set going up the hone progression is like polishing a turd. I know this from having to learn honing on my own and went through the same thing. In the beginning you also don't know what to look for and/or how to interpret what you are seeing. That takes a while to learn too. The absolute best way to learning honing is to get together with a member who is experienced in honing for some one on one instruction.

Personally I think you are creating far more work for yourself by using a 400 grit hone as a bevel setter. That is especially so if the blade has no chips and even then a 1K is all you need. If a bevel needs no major work, like removing chips, just a reset then a 3K should do the job. That leaves far less deep striations to remove than a 400 grit hone.

To jump from a 400 grit hone to a 3K and finish on a 10K hone is too wide a spread between hone grits. I'd try using the 3K as your bevel setter and get a 5K or 8K to fill the gap between the 3K and 10K hones.

In the end though I would really find a mentor for one on one instructions on honing. You can't believe how much I would have liked to have that option.

BobLife is a terminal illness in the end

-

01-02-2017, 12:41 PM #7

I would suggest using the 3k for longer. Looks like quite a bit of deep striations still likely from the 400. These will likely lead to a chippy harsh edge. Kill the edge and reset the bevel on the 3k. After removing all the deep striations then move on to the 10k. It will take a bit as it is a big jump but is doable. Make sure you keep your pressure light so as not to flex the blade or your honing wont reach the edge.

My wife calls me......... Can you just use Ed

Can you just use Ed

-

01-02-2017, 01:37 PM #8Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Others have pretty much hit the nail on the head. That's an intentional secondary bevel on the DE. What you have on your blade looks like either a burr/foil edge, or an unintentional secondary bevel because yours isn't quite set. Just to reiterate, 400 grit is far too coarse. Blade restoration/chip removal only. You want a good 1K, or a lot of time on the 3k.

You also didn't mention what type of hone you're using. A Naniwa 3k and a Weiwei 3K are not the same. The former is a 3K and the latter more like a 1.5K, or so it's been described by users that own both sets. The same trend follows to the 8K and likely to the 10 as well.

It will probably take a while, but were I using the same hones I'd probably drop down to the 3K and make sure that bevel was set properly. Maybe look into getting a good 1K (anything from naniwa, shapton glass/pro, Norton, King).

Most of the problems new guys run into fall into 2 categories - bevel not set and uniform, and too much pressure used while honing. Sometimes the 2 go hand in hand.

-

01-02-2017, 02:48 PM #9

Gentlemen

Thank you for your passionate and good advices.

I believe learning is a process where progress is made by making

mistakes AND not repeating them. Todays theory of "knife edge" on top

of bevel was debunked. I did manage to shave with it, not a perfect shave but

a shave still.

A 8000 grit stone is ordered and in the mail. I use the generic chinese ones from

aliexpress as, well, i still have no clear idea what i really need an what not. Whenever

i know what i'm doing i'll get decent stones and some beautiful gold etched straight razor

but meanwhile as learning is done, razors overhoned and stones used unevenly because

of perhaps wrong type of honing i'll stick to the cheap ones.

And for a last comment there was no way to guess DE blades have an intentional

double bevel. Thank for that information.

-

01-02-2017, 03:14 PM #10Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Yeah, I wouldn't have known either if I hadn't seen really close up pictures of them. I think with mass manufactured DE blades it's easier to go in shallow to get an edge roughed out, then come in a little steeper with a finishing grit to put that final shaving edge on it. Kind of like a mechanized version of the unicot process where you intentionally add a layer of tape at the finishing phase to get that secondary bevel.

You can mimic it with your straights if you like, just add a layer or 2 of tape or a similar buffer to lift the spine a touch. I don't do it myself, but I've read a few guides and seen where others like the results. YMMV. But the bevel has to be fully set first.

36Likes

36Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote