Results 1 to 10 of 12

Threaded View

-

01-02-2017, 08:10 AM #1

Possible solution to difficult situation in honing

Possible solution to difficult situation in honing

Hi

Many forums have threads that say "I'm trying to hone but nothing works. The razor just

won't become sharp" or such where beginners have do everything according to guides but still

the razor is dull. I had a similar situation. A razor that has a mirror edge that's dull and i

actually could pull a arm hair with its root when the hair was over the razors edge. The hair

was bent but not cut.

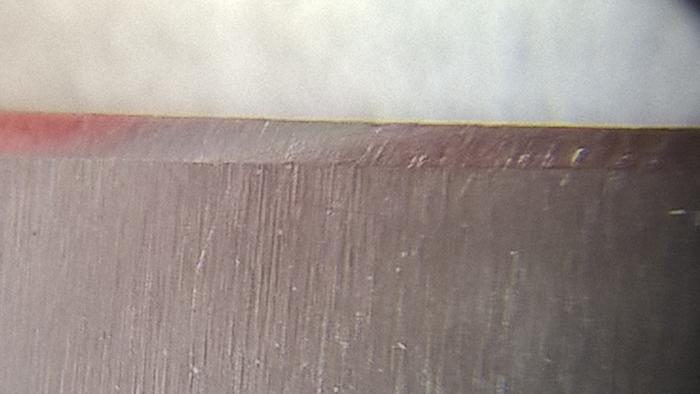

Here's a photo

It's a razor edge honed with 400 grit, 3000 grit and few minutes with 10.000 grit.

It has a shiny mirror edge. The blade looks bent but actually it's light playing around

with the polished edge. But so dull.

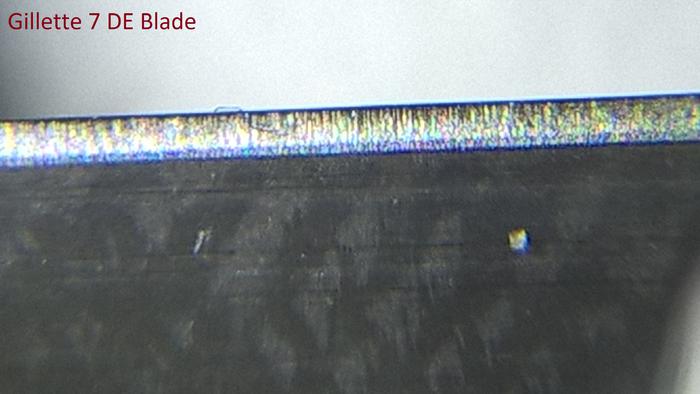

Then. I took a photo from a DE blade

The difference was that the actual tip of the razor has a "cutting edge" or how

should it be described. Think that's the part that does the cutting as opposed to a single form

bevel that's does not have a separate "knife edge" on tip.

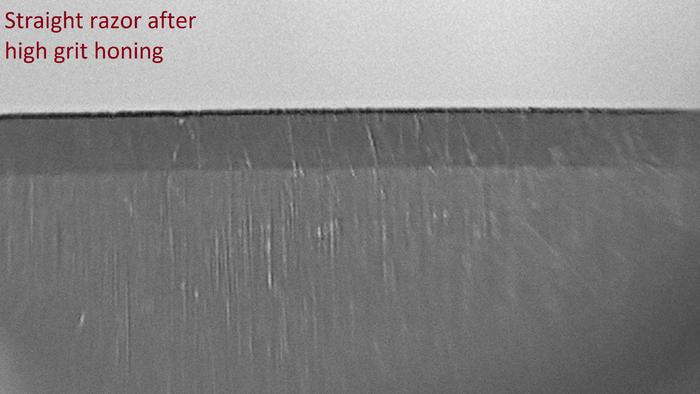

So next, about 400 laps with 10.000 grit stone

And same kind of "knife edge" appeared to the razor. I'm quite sure this is not a double bevel

resulting from honing with and without tape because i had that issue. It was resolved with

resetting bevel with low grit honing.

So now i tested with putting shave cream on small part of arm hair and the straight razor shaved the area

completely hairless.

So my theory is that when a razor is "properly" honed but mysteriously dull the reason MAY be that

the "knife edge" on top of bevel is missing. I assume that the knife edge is necessary because DE blades

have them.

36Likes

36Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote