Results 11 to 20 of 23

Thread: Newbie Honing Kit

-

02-04-2009, 05:35 AM #11

hone

hone

i didn't see this early.most advise is right but do this too.buy cheap razor and try to hone them.it will help you how to progress .Please buy microscope to see what are you doing with the edge.i am not home and using phone line.i hate it.when i got home i will read all messages and try to help you.good luck and never give up.

-

The Following User Says Thank You to hi_bud_gl For This Useful Post:

Cornelius (02-04-2009)

-

02-04-2009, 04:27 PM #12

Cornelius, the DMT's are a major PITA to hone with until they are (use Mike Meyer's Shrek voice for this next part) *really really* broken in. Even then, they are pretty darn aggressive. I have the best success with the DMT's when I use a 45 degree, heel leading stroke. Either straight down the hone, or X pattern if the blade is warped. Also use some dishwashing liquid in the water lube. Using the dishwashing liquid and the heel leading stroke will take some of the bite out of the DMT's.

It takes *alot* of work to break in DMT's. Much more than sharpening a few kitchen knives.

Personally, I think you have a great setup. That coticule should refine the rough DMT edge very well.

Edit: Pay extra attention to breaking in the edges of the DMT's. The ninety degree drop off on the edges of the DMT's are very unforgiving of any error in an X stroke. I've broken my 8E and EE in on the edges to the point that there is hardly any diamond/nickel plating left on about the last 1/8 " before the edge.Last edited by FloorPizza; 02-04-2009 at 04:43 PM.

-

The Following User Says Thank You to FloorPizza For This Useful Post:

Cornelius (02-04-2009)

-

02-04-2009, 05:21 PM #13

But... that's exactly what I did!

I dont know what's going on with this razor, but it looks cast rather than forged to me. Maybe one of these Pakistani blades I keep reading about? Or perhaps a Chinese product? What I find most strange is the absence of any clearly marked brand.

I dont know what's going on with this razor, but it looks cast rather than forged to me. Maybe one of these Pakistani blades I keep reading about? Or perhaps a Chinese product? What I find most strange is the absence of any clearly marked brand.

And I dont have any other dull razor left to try, they've all been sharpened by SRP honemeisters!

Ok.

-

02-04-2009, 05:24 PM #14

-

02-04-2009, 05:34 PM #15

325

325

CORNELIUS if blade doesn't have an writing in it could be it is pakistany that is really good.then forget about putting a good edge just play with it.it you have done 200 laps on 325 that razor's back should almost gone.is this blade wedge balde?if answer yes change to hallow ground a lot easier to learn.let us know how are you doing ok

don't worry about at heel you don't have bevel blade could be carved reason why .you just try hone you will get there.if you really want to heel use sircular motion only heel ok

-

02-04-2009, 05:54 PM #16

I thought the Pakistani razors were not good? - I dont know where it's from, see post number 3 above for an image. I blew the writing up so you can see if you can recognize / identify it.

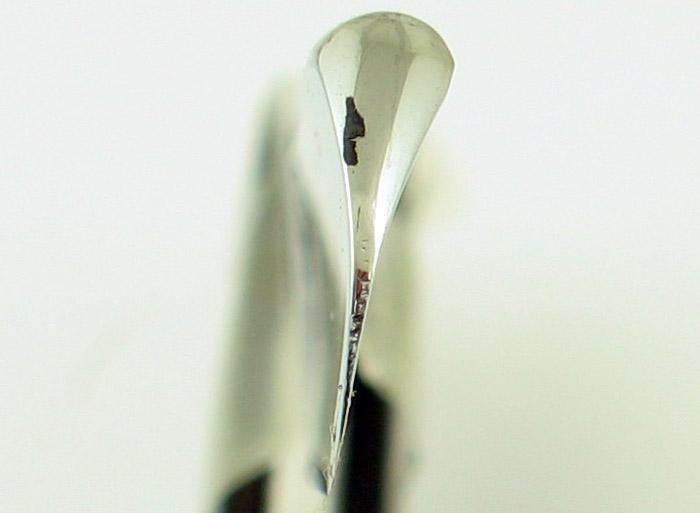

I dont think so, it looks rather hollow. Not sure, though. Here's a picture:

Ok. Thanks!

-

02-04-2009, 07:27 PM #17

That should certainly be enough laps on that coarse of a stone to put a bevel on anything. The steel might be of such poor quality that it is simply crumbling away. I had this happen on a dubl duck that had lost it's temper, and a pakistani blade, too. I ended up getting the pakistani to take a bevel on a finer grit hone, but it took forever. Too coarse of a grit just made the edge crumble.

To break in the edges of my DMT's, I took my Chinese 12k hone (which is very narrow), and used the side of it on the edges of the DMT's until they were noticeably worn down.

-

02-09-2009, 12:13 AM #18

So how do I break in the DMTs? Is there a standard procedure or do I have to hone razors until they finally become broken in at some point?

-

02-09-2009, 12:34 AM #19Coticule researcher

- Join Date

- Jan 2008

- Location

- Belgium

- Posts

- 1,872

Thanked: 1212

Put a good dense Coticule slurry on the DMT. Take a cabinet scraper, or any other flat piece of hard steel (like a wide chisel), place it flat on the hone and rub back and forth for 15 minutes. Apply decent pressure. Scrub the DMT with a scotch pad (the one you use for washing dishes) and some dishwashing soap, till it looks clean again.

That should do it. Check your razor under magnification, while honing on the DMT's. A DMT that is not broken in well, causes microchipping.

Hope this helps,

Bart.

-

The Following User Says Thank You to Bart For This Useful Post:

Cornelius (02-09-2009)

-

02-09-2009, 12:47 AM #20

Fantastic, thanks!

Damn, 15 mins...

I'll do that with the coarse, the fine and the extra-extra fine equally?

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote