Results 1 to 6 of 6

14Likes

14Likes

Thread: Just for grins

-

11-10-2014, 01:36 AM #1Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027 Just for grins

Just for grins

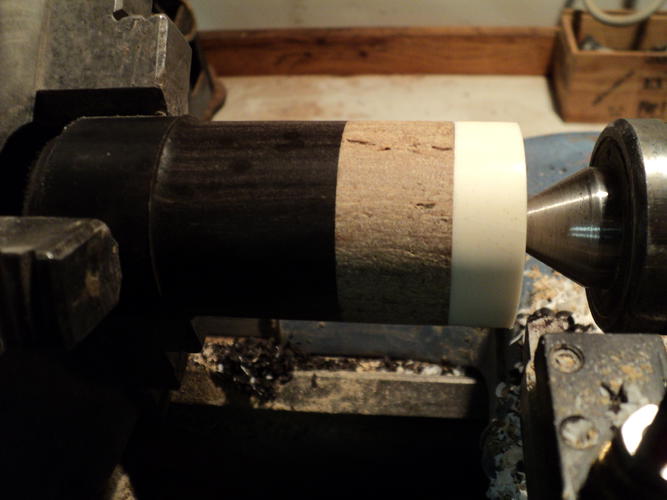

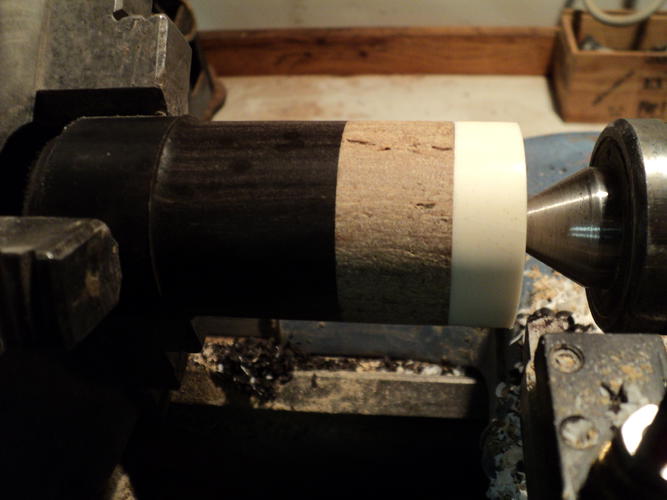

Almost all my brush handles are composits of many diff materials.they take several days to make.

This one is Ebony, Fossil seacow Bone and Ivory,Each segment is pricision turned to insure a seamless fit.

Than Line bored and dowelled in place.

They are turned exact before the hand work begins.

I get asked about how I do this all the time,thus this post.

CAUTION

CAUTION

Dangerous within 1 Mile

-

-

11-10-2014, 01:47 AM #2

So, you are saying trying to turn such a brush on a drill press will not work

If you don't care where you are, you are not lost.

If you don't care where you are, you are not lost.

-

11-10-2014, 01:50 AM #3Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

11-10-2014, 01:56 AM #4

Yep,,,

That's how I used to make'em,,,

That's how I used to make'em,,,

-

11-10-2014, 11:43 AM #5

SPose everyone starts somewhere LOL

I think I prefer a lathe also for spinning wood.

But true skill and ability come with time which is what only a few brush turners seem to show repeatedly here

Especially with composite handles of differing material densities etc.Saved,

to shave another day.

-

11-10-2014, 02:33 PM #6aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I can attest to his "seamless fits", they are truly that. I don't even have a lathe and am watching to learn...

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote