Results 1 to 9 of 9

17Likes

17Likes

Thread: CA finish problems

-

04-09-2016, 09:43 PM #1

CA finish problems

CA finish problems

here's a image of my latest brush bottom. seems the hardest part is getting the finish right. i'm using super glue and applying it on the lathe, sanding between coats applied with a paper napkin. i do the polishing with wet dry and/or micro mesh. always end up with shiny spots and dull spots am i sanding through the finish in spots? if so why is it so uneven in thickness?

-

04-09-2016, 10:20 PM #2I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Yes, you are sanding through the finish. I've had the same problem happen many times in that very location. I can't tell you exactly why it happens predominantly on the base, but for the amount of CA finishes I've done, it tends to only happen in this location. One thing I have found that helps is turning the lathe off and wiping a few passes on the base while its stopped. I think the problem is, is that more material is removed in this location compared to the side of the turning. You need to spend less time sanding in that specific location.

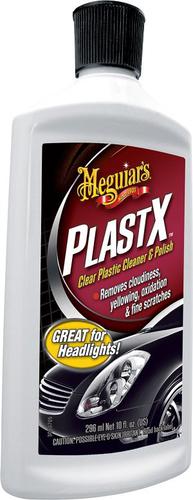

Not sure what grit you start with, or use in between coats, but I have found that anything below 1000 wet is too aggressive for CA on a lathe. Also, the speed at which you apply the CA is also key. I apply at 800 RPM, and also do all my sanding at 800 RPM. Any higher is unnecessary and will just burn through sand paper. Keep things ultra wet, and really make sure everything is fully cured before sanding. I've also found that micromesh is unnecessary as well. Try sanding from 1000, 1500, 2000, 2500 and then using a headlight scratch remover at high RPM to finish using paper towel and a very light touch. This is the process I use for CA and all my plastic handles as well. Of course, YMMV. This exact brand is what I use and have found it better than any plastic polish I've tried. Even on razor scales as a final polish, it leaves the finish super clear and glass like.

This is a great video on how to apply a great CA coat on wood turnings.

Last edited by HARRYWALLY; 04-09-2016 at 10:25 PM.

Burls, Girls, and all things that Swirl....

-

-

04-10-2016, 12:53 AM #3

Do you use the brand shown in the video? (i've been using the stuff from the dollar store) and is the thin enough or do i need to get some medium too? i've watched other videos that use both. thanks again for the info.

-

04-10-2016, 01:50 AM #4I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Do you really want to use CA you got from the dollar store on your beautiful handles? Who knows how good that stuff is.....

I have used the Hot Stuff brand, yes. You can get it at LeeValley If you really want to try that specific brand, but I haven't found a difference in good quality CA. I generally get my CA from the local RC store but only use the thin for the first 2 coats. Then I switch to this stuff BIG 8 OZ Bottle Flexible Thin Hyperbond CA Super Glue Cyanoacrylate "Flex" | eBay which is a flexible CA. The flex helps with any movement in the wood. I have found that if your not stabilizing, there's chance of the wood expanding and cracking the finish. This stuff doesn't crack quite as easy.

I know, it happened to me with a couple handles I did.Burls, Girls, and all things that Swirl....

-

-

04-10-2016, 01:55 AM #5

Enough of this technical talk you guys,, show us some beautiful brushes.

-

04-10-2016, 02:07 AM #6

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

Hirlau (04-10-2016)

-

04-10-2016, 02:39 AM #7

I could have used one of them on the streets when I was young for bonking 2 legged fish,,

-

04-10-2016, 11:49 AM #8

-

04-12-2016, 02:34 AM #9Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

I think the problem comes from being end grain. Traditionally in the woodworking world end grain must be sanded twice as much as regular grain, if not the end grain will look a lot darker. Naturally it soaks up more products.

In woodturning end grain is usually burnish with its own shavings right on the lathe and then the finisher.

-

The Following User Says Thank You to Martin103 For This Useful Post:

tintin (04-12-2016)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote