Results 1 to 6 of 6

27Likes

27Likes

Thread: My recent brush, build images

Threaded View

-

12-12-2019, 07:19 PM #1

My recent brush, build images

My recent brush, build images

Couple days ago I posted this brush here and should have put that thread in the gallery as it didn't contain any build images (moderators are welcome to move that thread).

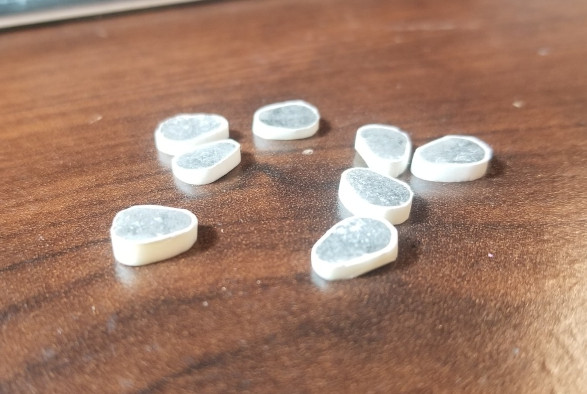

Thought I'd create a thread showing the images of the build I captured along the way. I don't have a lathe, just some hand tools, a drill and a Dremel; and this is only the second time I've done an inlay in anything.

The brush was designed using the hole saw method I've posted in the past, this has the advantage of being able to inlay the back of the brush while it's still only an inch high instead of trying at full length. Enough yammering, here's the pics...

-

The Following 4 Users Say Thank You to TheBaron For This Useful Post:

jfk742 (12-19-2019), Johntoad57 (12-12-2019), markbignosekelly (12-12-2019), tintin (12-12-2019)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote