Results 11 to 20 of 23

Thread: Brush I did today

-

05-11-2013, 12:11 AM #11Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

-

05-18-2013, 03:44 AM #12

Thanks for the picture. I'll have to try that technique.

-

05-18-2013, 03:52 AM #13Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

05-20-2013, 11:15 AM #14Senior Member

- Join Date

- Sep 2011

- Posts

- 224

Thanked: 20

Thanks a lot for the pic - I have a couple of questions:

Are you doweling first as part of the initial assembly and then turning, or are you glueing the pieces first, then turning (to final or close to final shape) and then doweling as sort of added insurance after the fact?

If you are doweling first, how are you aligning the drill holes?

Are you making your own dowels, using store bought dowel stock and cutting to length, or using the pre-made dowels with the groves cut in?

Thanks again for the picks and for showing your excellant work

-Gags

-

05-20-2013, 12:45 PM #15Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Thanks Joe

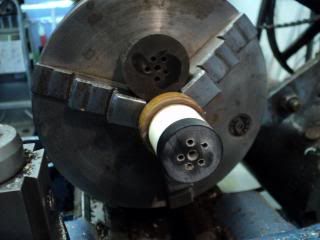

All the initial work is done on my metal lathe so I know all is concentric within a few thou.The small hole alighnment is done by marking a grid on both pces,drilling the holes on the drill press than re-chucked in the lathe and glued in place using the tailstock as a clamping device before being chucked on the wood lathe.

When I use dowel it is just standard hardwood dowel stock.

-

05-20-2013, 05:57 PM #16Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

This is how I glue them up,Is doweled as I am using African Blackwood,CoCobolo and lignum,not glue friendly woods.

The faces have to be perfectally machined or you will have glue lines (not a good thing).

After all is glued and set I will turn it between centers and have a multi wood pce ready for the wood lathe.

-

05-20-2013, 06:06 PM #17Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Love the schooling on technique. When I look at the brush the words "black tie affair " come to mind. Very nice !

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

pixelfixed (05-20-2013)

-

05-20-2013, 08:20 PM #18Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

05-20-2013, 08:24 PM #19

I like it, a lot. The mix of materials makes for a unique custom brush.

Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

-

The Following User Says Thank You to lz6 For This Useful Post:

pixelfixed (05-20-2013)

-

05-20-2013, 08:24 PM #20

Pixel, you should open a weekend workshop & teach basic & advanced wood working; make some pocket money.

I would send my kid to it. They don't teach it in the schools here.

22Likes

22Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote