Results 1 to 10 of 59

Thread: Latest custom builds

Hybrid View

-

07-08-2014, 10:57 AM #1Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Thanks Brono, and I will indeed continue to do whatever I want, and learn with every new razor shaped object I make and you are correct "several people have informed and indeed tried to HELP me and I have listened and I will try to do better in future.

I will go away and think very carefully on all of you constructive words and will try to do something that will meet with your approval in the future.

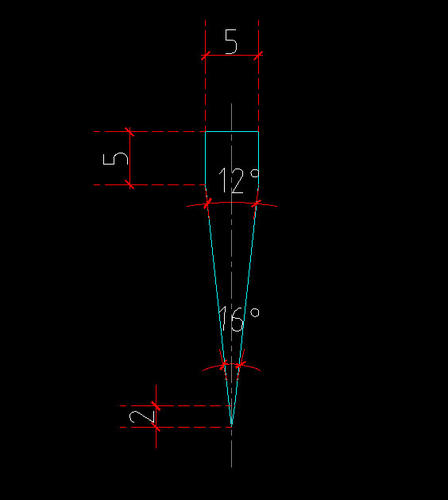

Or I could just "feck it" and do what I want to do as long as I'm having fun doing it I'm going to keep on doing whatever looks good. I've added another image showing a section through the offending razor shaped object, I don't know if they are correct or even if they are closer than the last one I posted but if someone wants to check them please do. Like I said only my 5th razor and I'm still learning.

-

07-08-2014, 11:07 AM #2

Drew - if you post things and ask for comments then you have to accept the good but also be prepared to take on some other advice. I don't see that Bruno was being critical - just pointing out some areas for you to consider. Basically if the wedge in the photo appears to hit the hone at the top of the spine - therefore, given that it's a 9/8" you have a blade width to spine width ratio of over 7 when the recommendation is 3.5 to 4 in order to end up with a bevel in the 18 degree area.

If you then introduce an element of hollow grinding you will achieve a much smaller bevel without the need for multiple layers of tape. Much as I like the look of what is on here I would not want either a bevel of that size or a need to tape to that extent when re-honing.

Take Bruno's advice for what it was intended - i.e. to help.

-

07-08-2014, 11:22 AM #3

You should not sell razor looking like that. If u think it looks good with a massive blade and a narrow spine, keep them for yourself or give them away for free but please dont post as a vendor with razors that are wrong made. It will only bite you in the end when you sell them with wrong geometry. If you have problems with the thickness of spines, just ask the guys here, thay will help you.

//Magnus

-

07-08-2014, 04:56 PM #4Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Ok just to clarify a few points I made the big one because I was asked to make it for a guy who wanted a big blade, the blade grind starts 5mm off the spine because I listened to what I was told by a few of you in a previous post and I was trying to achieve a 4:1 ratio (and its not far off that from what I can tell) he since asking me to make this for him jerked me around and then promptly disappeared! Since I made this one I did the other two and the grind on them is about a 3:8 ratio. So yes I am listening and I am taking your help on board, just when I read Brono’s post I obviously read it in a condescending way that it was obviously not intended.

I am always ready to listen to advice and constructive criticism I guess I took what was being said in the wrong tone.

-

The Following User Says Thank You to 3Drew101 For This Useful Post:

Bruno (07-08-2014)

-

07-08-2014, 05:48 PM #5

Thanks. Yes, I used the phrase 'razor shaped object' not to be insulting, but because it looks like a fine razor which is missing a structurally important element that is a key difference between a razor and a knife or microtome (which does have a completely flat grind).

Plain text communication always loses the information that would be present with intonation and body language. A simple phrase like 'that's nice' can be enthusiastic, sarcastic, insulting, bored, and many other things, but by changing the way it is spoken.

In any case, I did not intend to be condescending.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

07-08-2014, 08:28 PM #6

-

07-09-2014, 07:18 PM #7Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Ok I've just measured the big blade again and with the spine measuring 5mm across and the blade angle starting nearly 6mm from the spine it gives me a ratio of 4.715:1

So why can't I call this a razor? I know it should be between 4:1 & 3.5:1 but it's bloody close. So what structural important element is it missing?? Can someone please explain as I'm begging to feel a bit thick!!Last edited by 3Drew101; 07-09-2014 at 07:31 PM.

-

07-09-2014, 07:26 PM #8

-

The Following User Says Thank You to ncraigtrn For This Useful Post:

3Drew101 (07-09-2014)

-

07-09-2014, 07:36 PM #9At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,069

- Blog Entries

- 1

Thanked: 13249

Here you go.

http://straightrazorpalace.com/advan...-theories.html

and here

http://straightrazorpalace.com/razor...zor-angle.html

There are Google friendly formulas right there and instructions on how to measure accurately

As you can see the target of the Vintage razors was 16° or pretty close but the variance can be up or down from there depending on the Steel Factors and Grinds

-

07-09-2014, 08:04 PM #10Truth is weirder than any fiction..

- Join Date

- Jun 2012

- Location

- Land of the long white cloud

- Posts

- 2,946

Thanked: 581

Well, you certainly have a good eye for style and design. Once you get your geometry issues sorted, you will be on a winner. Don't get discouraged. Everyone who has commented is trying to help. But if you gonna do it, might as well do it right.

Into this house we're born, into this world we're thrown ~ Jim Morrison

86Likes

86Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote