Results 1 to 8 of 8

Thread: My next custom build

-

08-18-2014, 12:58 PM #1Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11 My next custom build

My next custom build

This is what's been keeping busy lately.

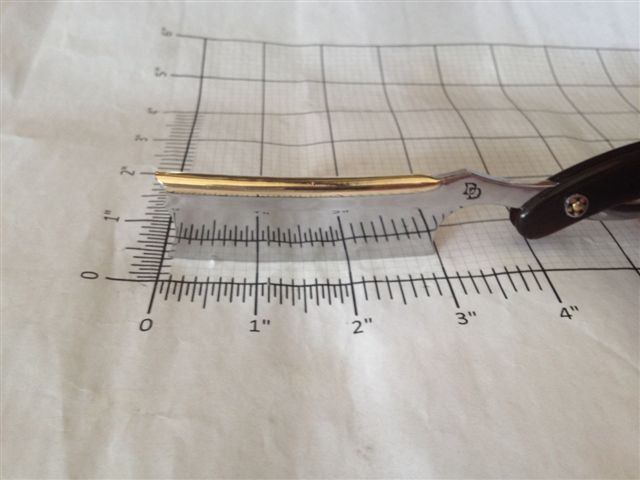

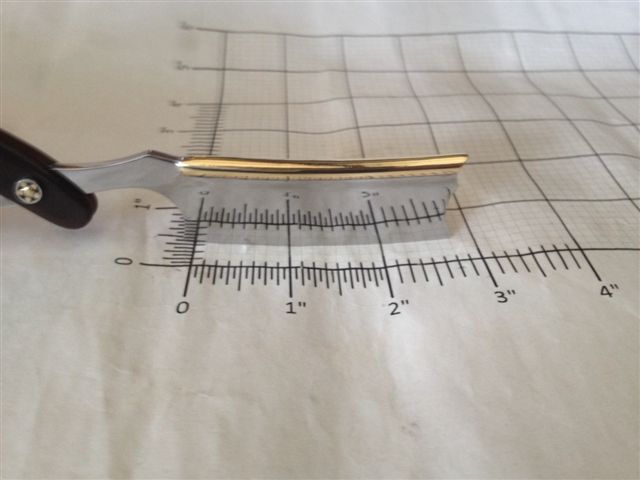

its an 8/8" wedge brass frameback, with dark brown horn scales, mosaic collars, brass pins and a pewter wedge.

good fun to make and it shaves better than it looks. I'm really happy with how this one turned out, I love brass frame back razors!!

-

The Following User Says Thank You to 3Drew101 For This Useful Post:

Sandycrack (08-22-2014)

-

08-18-2014, 02:21 PM #2Senior Member

- Join Date

- Jul 2013

- Location

- Shreve, Ohio

- Posts

- 229

Thanked: 68

Nicely done, that's a good looking straight. Question though- With a brass frameback I would assume you have to tape it yes? Not only to save the finish but brass would get eaten up much faster than the blade while honing.

-

08-18-2014, 02:24 PM #3

Very cool lines to this razor. The brass really adds to the overall look.

-

08-18-2014, 10:30 PM #4Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Hi wynndow,

Yes you will have to tape it when you hone this one otherwise it will go through the brass back really quickly.

-

08-19-2014, 07:25 PM #5Junior Member

- Join Date

- Jul 2014

- Location

- In the middle of the Pacific

- Posts

- 29

Thanked: 10

Hi Drew.

I think that the razor is very pleasing to the eye, and I like the subtle smile as well. All of the lines and curves fit and flow very well together, but I did have one question (or observation). I might be wrong, but isn't the concept of a frameback to have a very thin blade and the frameback portion to add strength; stability; and proper honing geometry to the blade? So this wedge would be a faux frameback for aesthetic purposes only, yes?

-

08-22-2014, 11:47 AM #6

If you look at the blade grind - it's almost wedge like and the Frame helps create the correct honing angle. The original framebacks were intended for exactly the same purpose - albeit that the blade would have been much thinner than Drew's. The faux framebacks were ground from a single piece of steel but longitudinally (I think that's the right word) which also created a near wedge - so Drew's description is accurate I believe.

Nice work again Drew, they seem to be getting better and better.My service is good, fast and cheap. Select any two and discount the third.

-

The Following User Says Thank You to UKRob For This Useful Post:

3Drew101 (08-22-2014)

-

08-22-2014, 11:59 AM #7

Me like shiny, sharp, pointy thing

SRP. Where the Wits aren't always as sharp as the Razors

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

08-22-2014, 12:22 PM #8Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Thanks guy's,

yes the brass back is to give it the correct honing angle, the steel I used for this one was 4mm thick (I ordered the wrong thickness but waste not want not) and after grinding and polishing was closer to 3.5mm think. I fixed up this Greaves brass frameback last year and the blade thickness at the point it met the brass back was close to 3mm so mine is pretty close, but if it makes you feel better you can call it a faux frameback, you can call it Mary if you want it doesn't matter to me it's gone now so on to the next one...

13Likes

13Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote