Results 1 to 8 of 8

Thread: Back with a new toy

-

04-09-2015, 10:06 PM #1Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11 Back with a new toy

Back with a new toy

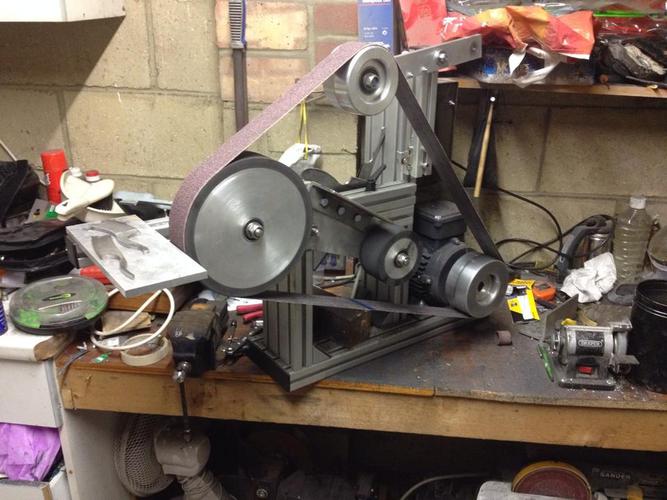

Its been a while since I posted anything, I’ve been locked in a room doing the day job in order to put together a decent knife grinder.

Living in the UK you just cant get them (unless you’ve got a grand or so kicking about the place that your not using), so I bit the bullet and built one myself after spotting this on you tube I thought it looked like a decent set up.

https://youtu.be/fiWhflmTACc

so I set to work and after getting a piece here and a piece there I came up with this.

The wheels from USA knife maker (8x2” & 4x2”) and the drive and tracking/tension wheel off a guy in the US I found on eBay, the extruded aluminium came from Austria but I did get the drive motor (three phase 1hp) and inverter over here, it will fit a 72” belt but you can open it up to 2m if you want to depending on what size belt I can get hold of.

I mounted the 8” and 4” so I had the flat platen in-between them so I could just undo the bolt and turn from one to the other without the need to change an arm on the grinder and I’m really pleased that it works great.

It defiantly makes a big difference having the right tool for the job, I’ve been playing with it today and managed to get these four cut and first grind done ready to heat treat tomorrow.

Three 8/8” hollow ground and a big 10/8” hollow ground

All I can say is its good to be back doing something that I love doing, and fingers crossed be able to make a living out of it. The good thing is there doesn’t seem to be anyone else in the UK putting together handmade straight razors co not much in the way of competition!

-

The Following User Says Thank You to 3Drew101 For This Useful Post:

Geezer (04-10-2015)

-

04-10-2015, 02:41 AM #2Senior Member

- Join Date

- Jul 2014

- Location

- Pennsylvania

- Posts

- 100

Thanked: 36

Nice job,good luck.

-

04-10-2015, 02:48 AM #3

Your well on your way brother. Keep us posted on how the turn out. Glad to have you back.

-

04-10-2015, 04:04 AM #4

very nice great job

great incorporation of the wheels with the platen all in 1 set up for most works it should cover it just a 2" maybe for full hollows

what was you build cost for the parts etcSaved,

to shave another day.

-

04-12-2015, 07:49 PM #5Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Sorry I've not replied sooner but I've been busy playing with my new toy

The first one is a nice little 13/16" with dark horn scales, brass collars and a pewter wedge.

And its bigger brother an 8/8", it even rings when you pluck it.

I'm really happy with how the grinder is working out for me, it's going to save me a lot of time and effort and give me better results than i'd ever hoped for. I'm one happy bunny..

-

04-12-2015, 08:02 PM #6Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

Hi Substance,

The total build cost including a full set of belts (from 36g up to 2500g and a couple of cork polishing belts) set me back around £750. I know that's a lot but considering you cant buy these types of belt grinders in the UK very easily ( I only found a couple of engineering firms that do them) and the ones you can get hold of are around the £1200 mark for one of a similar spec to mine I don't thing I did to bad

-

04-12-2015, 09:45 PM #7

very good

the exchange rates & postage are the killer to get a quality branded item here in Aus

nice initial works also keep posting them as they develop

great stuffSaved,

to shave another day.

-

04-12-2015, 09:51 PM #8Member

- Join Date

- Jul 2013

- Location

- Bracknell UK

- Posts

- 41

Thanked: 11

17Likes

17Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote