Results 1 to 10 of 21

Thread: 9/8 "Kami-Cleaver"

-

05-23-2015, 05:06 PM #1

9/8 "Kami-Cleaver"

9/8 "Kami-Cleaver"

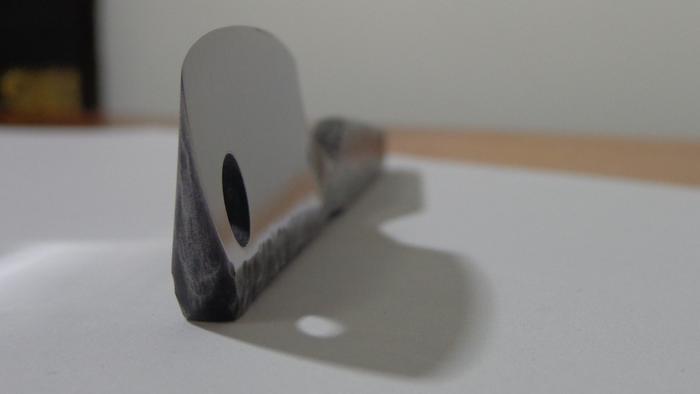

One of my more recent Kamisori. 9/8 Western grind in O1, a nice smile and a fun forged finish

Fun project!

Fun project!

Silverloaf

Silverloaf

-

The Following User Says Thank You to silverloaf For This Useful Post:

nipper (09-21-2015)

-

05-23-2015, 05:08 PM #2

Turned out quite nice! I shall expect delivery next week?

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

05-23-2015, 05:31 PM #3

If I don't ask this question I'll forget.....when you hone this and the hammered spine is sitting on the hone....wait, you must have hammered it then ground it so the spine was perfectly parallel and while not all of the metal is on the hone (the spine), there is enough to sharpen the blade....If this is too stupid a question, I'll understand if you don't answer.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

05-23-2015, 05:45 PM #4

not a stupid question at all, thanks for asking! The forging is done prior to heat treat and initial rough hollowing of faces as well is done prior to heat treat. After heat treating I more accurately rough grind the blade faces, taking the edge down to a suitable thickness and then set the bevel to create a flat contact on the spine. I then finish grind the faces and walk the grind up to the spine, all but eliminating the wear i created. the razor lays flat and in plane on the hone at this point and I usually finish hone with one layer of tape so the junction of blade face and hammered spine looks as it does here. Note that not all the metal of the spine needs to sit on the hone, there can be voids in there, but one thing to keep in mind is that a rough texture at that junction can chew up the hone a bit while creating a flat contact point. lightly sanding that area before initial honing can break the hard edges suitably.

Last edited by silverloaf; 05-23-2015 at 05:48 PM.

Silverloaf

-

-

05-23-2015, 05:56 PM #5Senior Member

- Join Date

- May 2015

- Location

- Traverse City, Michigan

- Posts

- 141

Thanked: 5

That look nice! Is there a reason for making the edge more half circled than flat across like other straights? New to straights so curious about the edge!

Thx.

-

The Following User Says Thank You to SirMike For This Useful Post:

silverloaf (05-23-2015)

-

05-23-2015, 06:04 PM #6

That is a great looking razor , love a smiling blade and the hole takes some of that tie end weight off , Great execution. Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

The Following User Says Thank You to tcrideshd For This Useful Post:

silverloaf (05-23-2015)

-

05-23-2015, 06:32 PM #7

my favorite vintage blades are ones with a smiling edge. I find it more maneuverable for my own face. heres a thread and link to some thoughts:

http://straightrazorpalace.com/begin...ling-edge.htmlSilverloaf

-

05-23-2015, 07:18 PM #8

All of the customs I,ve had made are smilers , just can't beat em. Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

05-23-2015, 07:28 PM #9I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Love it!!!!

Burls, Girls, and all things that Swirl....

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

silverloaf (05-23-2015)

-

05-23-2015, 07:34 PM #10

That's an awesome razor! Great work. I would be a bit nervous to put it to my face though, I think. No that's not true.

If I had it, I would have to try it. Smarter than I look or, not as dumb as I look. Whichever you prefer.

Smarter than I look or, not as dumb as I look. Whichever you prefer.

46Likes

46Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote