Results 1 to 4 of 4

Thread: Wade butcher restoration

-

06-10-2015, 06:32 AM #1

Wade butcher restoration

Wade butcher restoration

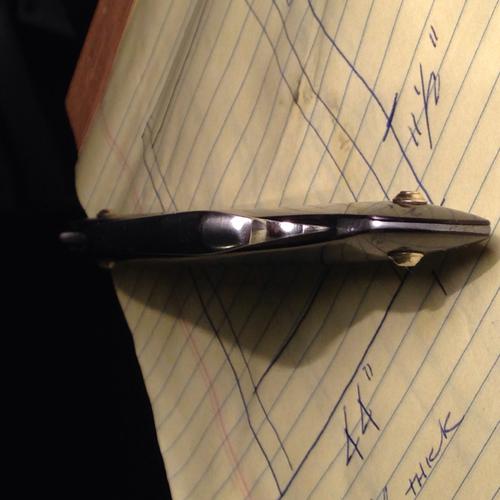

Just finished this for a trade. Black horn for scales domed and stepped collars, lead wedge made from a shotgun slug. I impressed myself with this project, the balance is perfect. It's weird how such a heavy blade can feel so nimble while shaving. I purposefully had the razor balancing where your thumb contacts the tang while scales are inline with the razor. What I didn't expect was it sit so well balanced while shaving.

The blade was sanded out to 1500 and then brought to a near mirror polish, I thought it looked completely wrong and also made the pitting look out of place. I ended up sanding it back down with 600 grit w/d. The scales were also finished with 600 grit but was then buffed with black Emory. Gave it a nice glow but kept it almost matte.

The pin hole was sloppy so I opened it up then bushed it with a length of brass tubing. I should have paid better attention to the blade. I had the blade closing centered in the scales and then realized that something didn't look right. The tang has a twist in it making it look torqued. I was going to ship it but it's driving me nuts, I'm going to taper some washers and secure them with ca to correct blade when it closes.

The edge this thing took is maybe the best I have felt. Super smooth and super sharp.

Last edited by jfk742; 06-10-2015 at 07:16 AM.

-

06-13-2015, 06:09 AM #2

Not sure you can see it in the first pic but the blade is torqued out of line to the scales by about 5 degrees. It was driving me nuts. This "fix" took me like 4 tries. I had to get the thrust washers not only glued to the scales but shaped correctly to get the blade to look straight up and down but also close center.

Here's the payoff pic:

All right, sandy crack, waits over. I'll test shave in the morning then stick it in the post!

-

The Following User Says Thank You to jfk742 For This Useful Post:

sharptonn (06-13-2015)

-

06-13-2015, 04:00 PM #3

Nice job! Of all the details in the world, the finest are sometimes unseen.

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

06-22-2015, 09:33 PM #4

that is sure to be a great shaver.

instagram - @suckerpunch_daycare

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote