Results 1 to 10 of 37

Thread: Birth of a new custom razor

-

12-23-2015, 07:14 PM #1

Birth of a new custom razor

Birth of a new custom razor

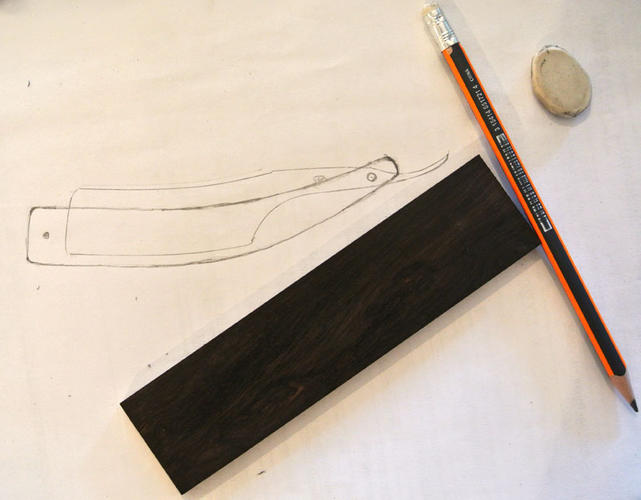

I would like to show you how I make a custom razor. It was made for a buddy in Hungary.

After the planning I cut the razor from the steel and shaping it.

To be continued...gregg

-

-

12-23-2015, 07:22 PM #2

The grinding process before the heat treating.

I have a simple machine but next year I can work with a professional grinder.

To be continued...gregg

-

The Following 9 Users Say Thank You to gregg71 For This Useful Post:

engine46 (12-24-2015), jmercer (12-24-2015), MJC (12-26-2015), nipper (12-24-2015), puketui41 (12-26-2015), RezDog (12-23-2015), ScottGoodman (12-24-2015), spazola (12-23-2015), Thisisclog (01-06-2016)

-

12-23-2015, 07:44 PM #3

Heat treating process. I would like to say thanks to the guys in The Forge topic for their help!

My process:

I leaved 1.5 mm thikness of the edge.

soaking: 805C / 1480F, 8 min.

quenching oil: 55C 20 sec

tempering: after cooling to room temperature, 210C 2x1h (between cooling to room temperature)

After this I sanded a few tenths of millimeters from the edge.

To be continued...gregg

-

The Following 5 Users Say Thank You to gregg71 For This Useful Post:

engine46 (12-24-2015), nipper (12-24-2015), RezDog (12-23-2015), ScottGoodman (12-24-2015), Thisisclog (01-06-2016)

-

12-23-2015, 07:48 PM #4

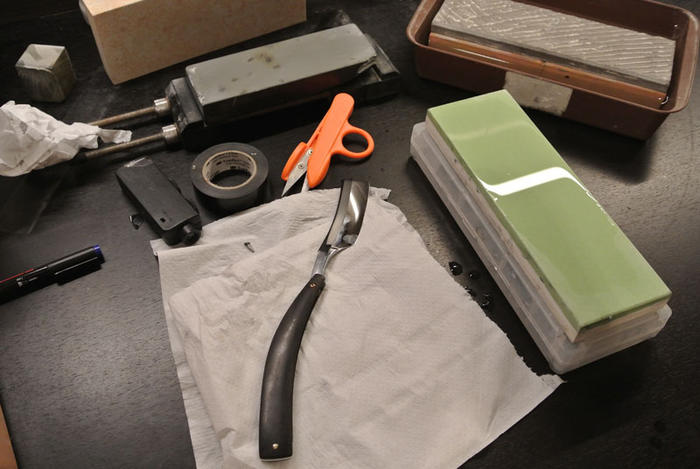

Hand grindig for the mirror polish.

Mirror polish.

Making the scales.

To be continued....gregg

-

The Following 7 Users Say Thank You to gregg71 For This Useful Post:

ajkenne (08-15-2016), engine46 (12-24-2015), jmercer (12-24-2015), nipper (12-24-2015), RezDog (12-23-2015), ScottGoodman (12-24-2015), Thisisclog (01-06-2016)

-

12-23-2015, 07:53 PM #5

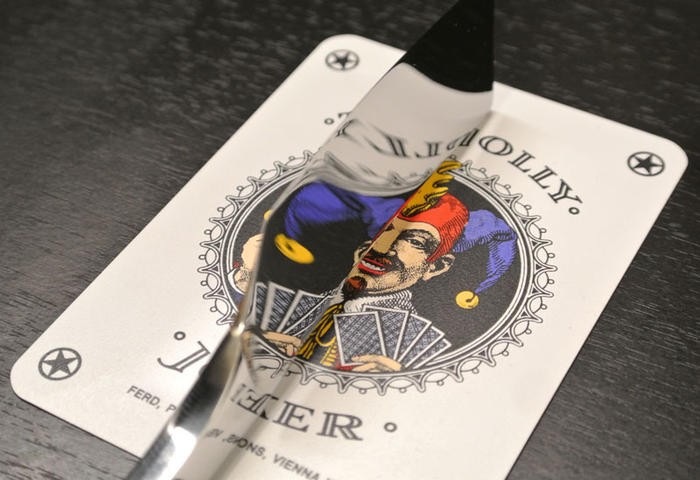

Honing process. As a finishing step I use Japanese natural stones and Kanayama Cordovan Strop.

The finished product.

- O1 tool steel hardened to HRC 61

- 7/8" (23mm) wide blade

- Quarter hollow grind

- Mirror polish blade including the hollow ground

- Grenadil scales and camel bone wedge

- Phosphor-Bronze pivot bearing washers

- Nickel-silver wedge/spacer pin with stainless steel washers

- Adjustable stainless steel pivot pins

Thanks for watching.gregg

-

The Following 25 Users Say Thank You to gregg71 For This Useful Post:

bluesman7 (12-25-2015), BobH (12-23-2015), ChopperDave (12-24-2015), dooey (01-14-2016), engine46 (12-24-2015), evnpar (12-23-2015), Gipson (12-24-2015), HARRYWALLY (12-24-2015), JAK (06-15-2016), jfk742 (12-23-2015), jmercer (12-24-2015), lz6 (12-24-2015), MattCB (12-25-2015), MichaelS (06-10-2016), MJC (12-26-2015), nipper (12-24-2015), RezDog (12-23-2015), ScottGoodman (12-24-2015), spazola (12-23-2015), Substance (12-27-2015), Thisisclog (12-26-2015), tintin (12-23-2015), Walterbowens (12-23-2015), Wolfpack34 (12-23-2015), WW243 (01-06-2016)

-

12-23-2015, 08:09 PM #6

Great job.

Tremendous pictorial, thanks for sharing.Tony

-

The Following User Says Thank You to Thug For This Useful Post:

gregg71 (12-23-2015)

-

12-23-2015, 08:18 PM #7

That is amazing! Great craftmanship

-

The Following User Says Thank You to monkeypuzzlebeefeater For This Useful Post:

gregg71 (12-23-2015)

-

12-23-2015, 08:19 PM #8

A beautiful razor than anyone would be proud to own. Thanks so much for sharing the process in such detail. I really enjoyed it.

Richard

-

The Following User Says Thank You to evnpar For This Useful Post:

gregg71 (12-23-2015)

-

12-23-2015, 09:23 PM #9

Thanks for the read along. The razor looks good and I really like finish on the scales.

-

The Following User Says Thank You to jfk742 For This Useful Post:

gregg71 (12-23-2015)

-

12-24-2015, 03:30 AM #10

Super interesting pictorial.

It's great to study different build techniques and methods.

The outcome is one heck of a razor!

Thanks for sharing.

Pete <:-}"Life is short, Break the Rules. Forgive quickly, Kiss Slowly,

Love truly, Laugh uncontrollably, And never regret ANYTHING

That makes you smile." - Mark Twain

-

The Following User Says Thank You to petercp4e For This Useful Post:

gregg71 (12-24-2015)

126Likes

126Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote