Results 1 to 10 of 20

Thread: 1st actually razor build

-

01-07-2016, 02:46 PM #1

1st actually razor build

1st actually razor build

A while back I had posted some fixed blade razors, only to learn that I knew very little about razors and their geometry. So with the advice I was given on that post I built this. I still need to work on this type of grind, I feel like maybe I went too thin on it because it actually flexes a bit when I was honing it (something else I need to work on). So, as always I am open to constructive criticism and critique. Thanks for looking!

Stock removal 1/4" O1 tool steel with rosewood scales

-

The Following User Says Thank You to markjeffrey For This Useful Post:

Euclid440 (01-07-2016)

-

01-07-2016, 03:03 PM #2

The grind, and the entire razor, are very well done! Nice work

-

01-07-2016, 03:23 PM #3Senior Member

- Join Date

- Jun 2013

- Location

- Pompano Beach, FL

- Posts

- 4,040

Thanked: 634

Very very cool. How is the shave?

-

01-07-2016, 03:36 PM #4Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,310

Thanked: 3228

It's not a full hollow grind till it does flex. Just ease up on the pressure when honing. Overall it looks good but I am not a fan of that particular heel design and the pinning could use a bit of work. All very minor points though.

BobLife is a terminal illness in the end

-

01-07-2016, 04:09 PM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

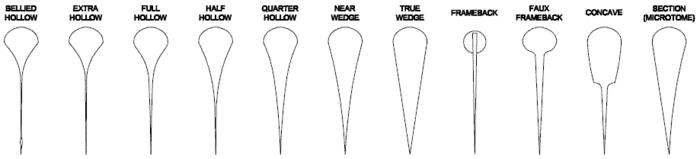

Looking at the grind makes me think that you must really be leaning on that blade on the hones if it is flexing very much.

You can see in the picture that blades get ground very very thin. On the full and extra hollow blades the heel is usually stabilized with the type of grind. For a first project it has a very nice and even looking grind, and quite a nice smile. All in all I would say a pretty nice razor.It's not what you know, it's who you take fishing!

-

01-07-2016, 04:35 PM #6

Looks good to me - although I'm also not keen on the heel design. Looking at the front view it looks to sit perfectly centre which suggests that the overall shape is spot on. Just one tip that's not been mentioned - it's usual to have a wedge rather than spacer - this helps to create a curve in the scales and allows the tang to sit in the scales without rubbing against the sides of the scales.

My service is good, fast and cheap. Select any two and discount the third.

-

01-07-2016, 04:40 PM #7Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,310

Thanked: 3228

You can still have a "shoulderless heel" in a full hollow.

The straight razor - Straight Razor Place Library

BobLife is a terminal illness in the end

-

01-07-2016, 06:14 PM #8

Thanks for posting this .

That's a lovely razor you'veade there

Cheers Paul

-

01-07-2016, 07:47 PM #9

Thanks everyone for your comments!

With the pinning, do you mane the edges? I kind of thought that.. I need a smaller hammer. Or do you mean they should be more polished? I kind of like the hammered look, just wondering if you could elaborate. Thanks Bob

I didnt feel like I was honing very hard.. But I usually make knives, so I obviously probably was. It was about the bottom 1/4" of the blade I noticed the flex at. Is there a preferred grind that is more sought after than any others? Looking at that chart I feel like the first 3 hollows would be really hard to achieve. Thanks!

Thanks, I ended up sanding 2 brass washers down really thin to keep the scales from touching. Is this a no no? The spacer is tapered slightly, but not nearly enough to curve the scales. It didnt seem to want to sit perfectly straight in there until I finally just decided to peen the pins, then it was pretty bang on, a bit of a sigh of relieve for sure. Thanks again!

Thanks for that link Bob, I will reference that for my next one

-

01-07-2016, 09:21 PM #10Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,310

Thanked: 3228

I was thinking of a more smooth look to the heads but if the hammered look was what you were aiming for you nailed it. The other point on the pinning was the flat washers. I think domed washers finish off a pinning job better than plain flat ones. Again that is a personal preference and the way vintage razors are pinned, usually.

I don't think there is a general consensus on which is a preferred grind. That would vary on an individual basis, I think. Not being a razor maker I would think the first 3 hollow ground types would be hard to grind without a lot of skill and lead to more rejected blades than with other heavier grinds. I am sure someone who actually does make razor blades can say for sure on that score.

The only thing I have against the reverse curve you did on your shoulderless blade is that it is just another place to cut yourself on a blade point. A point on the toe is enough for me to worry about without having to watch the heel also. Again that is a personal preference and I can't recall seeing any vintage razors with that reverse curve at the heel. If it was useful to have one I think they would have been more common when straight razors were in there heyday.

BobLife is a terminal illness in the end

35Likes

35Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote