Results 1 to 10 of 82

Thread: Work in Progress: Pete's razor

Threaded View

-

12-27-2016, 11:14 PM #1

Work in Progress: Pete's razor

Work in Progress: Pete's razor

I like making razors in wootz and Damascus because I am a steel guy. And I don't make a WIP thread often any more because after a while, it gets old to take the same pics again. However, Pete contacted me to make a razor for him, and it had to be 'special'. As in: not 'just' some complex Damascus or wootz.

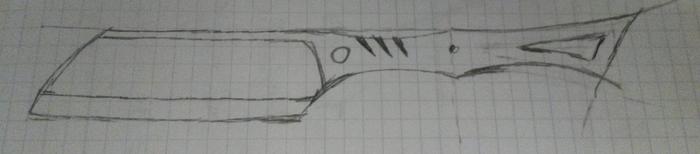

Allright, so without constraints, I started drawing and this is what we ended up with. I feel that this will be a special project indeed. The general shape is like this:

The body of the blade will be a Damascus that I made myself, using 14 layers of O2 and 15N20 in a spiral pattern. The edge section will be a 1/4" strip of wootz. And in between those 2 will be a thin strip of Damascus with a high layer count with laddered vertical stripes.

This is ambitious. I chose those steels because the heat treatment will be critical. Wootz is very shallow hardening. And I don't want the strip of wootz to tear off during HT. So my Damascus for the body is going to contain O2 to make it through harden. and the layer in between contains 1095 and 15N20. Which theoretically, I hope, means that upon quenching this blade, everything will harden more or less equally so that it will not tear itself apart.

Etching will be another challenge, because wootz needs a completely different etching method than the rest of the blade. So I may need to etch it in several ways, with the other part masked. that is why I added the ladder layer between the wootz and the body. that will be where the 2 etching methods will touch, eventually.

Still not quit satisfied, and with the request to use orange and green somehow, I decided to add 2 large spesserite gems (one each side) where I drew the circle, and then use green MOP kirinite scales.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

ScottGoodman (12-28-2016)

364Likes

364Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote