Results 1 to 10 of 10

24Likes

24Likes

Thread: Merkur Restoration

-

07-23-2017, 07:09 PM #1

Merkur Restoration

Merkur Restoration

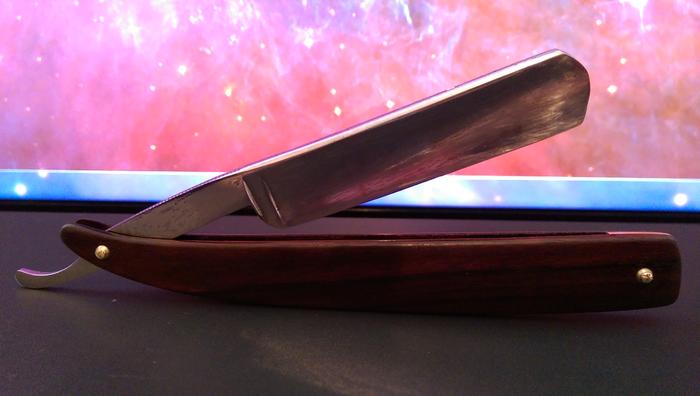

A friend asked me to restore his late fathers Merkur vintage razor.

The original scales were cracked so they had to go. Shame about the Merkur sign because I really like that symbol .

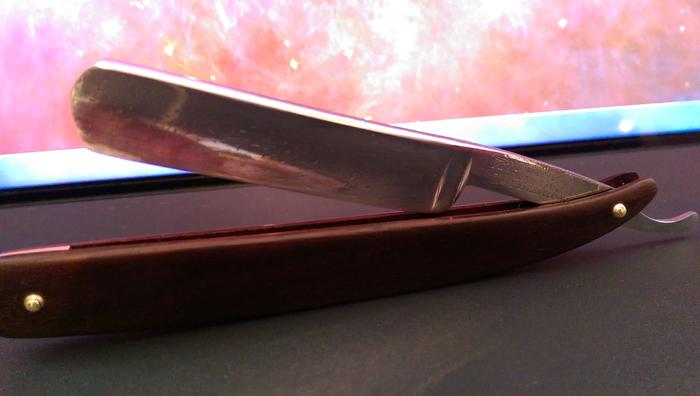

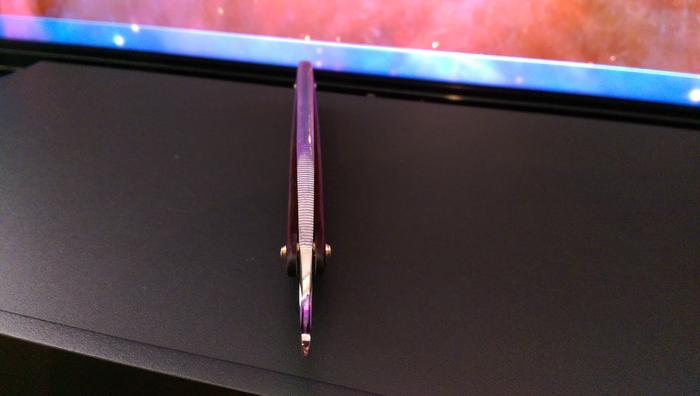

I had free reign over this job so I designed my own scales to follow the contour of the spine. I used a type of Ebony which is dark brown with black streaks. Thinned by hand to about 3mm ish, I'm guessing

Being a hollow grind I thought I could get away with a copper wedge . The wedge had to be specific, allowing the spine and scales to sit parallel and I used brass pins,collars and internal washers.

The blade had deep pitting and scars on the spine, so I did the spine starting with 240 grit paper. The rest of the blade I started at 400 grit. Finishing the whole this with 3000 grit and then polish.

I had to leave a few pits because the blade was too thin to even get near them..

I have yet to hone it up , I'm still waiting for the oil to fully dry on the scales/ 2 coats of true oil and I will finish it with beeswax.

Lovely blade and I cant wait to test shave it.

Surprising to me is how cheap these blades go for . I think I want one , one day ..

Cheers guys. (sorry the pictures are so dark)

Last edited by JOB15; 07-23-2017 at 07:12 PM.

-

07-23-2017, 08:41 PM #2

Nice job-Beautiful wood on the scales, brass hardware, and I love that copper wedge (been wanting to try that myself, maybe with some bulls-eye copper collars). I admire your bravery in sanding into deep pitting on that hollow ground. I've heard great things about Tru-Oil; I need to try it sometime.

Last edited by ScoutHikerDad; 07-23-2017 at 08:44 PM.

-

07-23-2017, 08:58 PM #3

Nice job, the scales are proportioned nicely.

Freddie

-

07-23-2017, 09:05 PM #4

-

07-23-2017, 09:10 PM #5

Nice job, the grain looks great in those scales with the contrast running lengthwise. Good choice of wedge, steps it up a notch in classiness.

"Go easy"

-

07-24-2017, 11:35 AM #6

That is one great restoration. It all came together very well and is one classy looking razor

Look sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

07-24-2017, 12:00 PM #7

Nice job, I'm sure he will be very happy with the results.

Fact: Opinions are not the same as facts... Well, that's my opinion anyway

-

07-24-2017, 12:21 PM #8

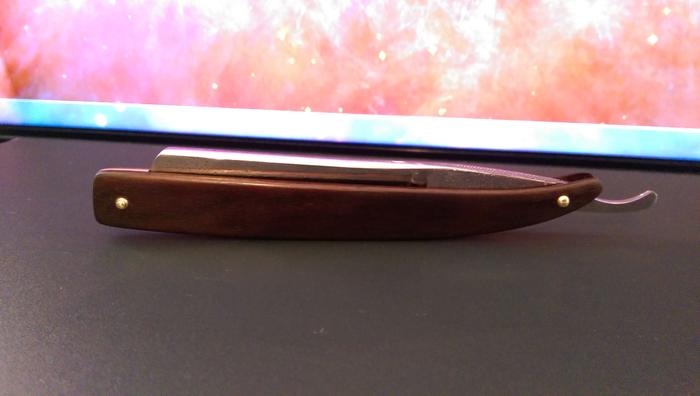

Cheers, I'll post a daylight picture once I put a killer edge on it..

-

07-24-2017, 01:50 PM #9

Great work sir, I too have been thinking about using copper. After seeing it I like the look a lot. It could really make the right material pop.

Nothing is fool proof, to a sufficiently talented fool...

-

07-29-2017, 03:52 PM #10

Today I put an edge on this blade and had a shave ..

I started with the Shapton Glass 500 . I think the DMT would have been too much.

No circles , just slight X's with no pressure and gave it a bevel.

Then i killed it and went to the Naniwa 1k. Same thing light strokes and set the bevel.

I then went 5k,10k Chosera, minimal strokes and onto the 16k Shapton Glass with 8 strokes.

Then I finished with the Escher 100 strokes with water only.

The shave was amazing. Smooth and sharp, everything you would want from an edge.

I took a few daylight pictures.

For the last week the blade has sat in my view and I really got to appreciate the shape of the scales .

Onto my next project : W&B 9/8ths

Cheers

Last edited by JOB15; 07-29-2017 at 03:54 PM.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote