Results 1 to 10 of 11

Threaded View

-

11-29-2020, 07:02 AM #3Senior Member

- Join Date

- Aug 2020

- Location

- Roseville, CA (30 minutes north of Sacramento)

- Posts

- 246

Thanked: 7

continuing...

Once the wedge was glued in place, I took it to the drill press and laid the scale perfectly flat like in the picture. (I did it this way because the wedge was sanded in a wedge-shape, and the drill press would not have made a perfectly straight hole). I went into the original hole in the scale, and drilled through the wedge.

Once the wedge was drilled, I placed the pins and blade in place, and double-checked that:

a) the blade cleared the wedge when closed

b) the wedge was sufficiently wedge-shaped to hold the scales opened.

c) the wedge was the correct width to stop the blade when in the closed position

Once I knew everything was good, I glued the other scale to the wedge (I know, I know...not everyone glues the wedge in place), and then sanded the wedge to its final shape. A little 200-grit sanding again to make everything look delicious, and they are done. Then I installed the pin and peened it. (Wifey chose the nickel-silver pins instead of the brass ones.). Now it's time to apply the linseed oil.

Ah yes...another good tip I learned. Once everything was done, AND BEFORE THE PINS WERE SET IN PLACE, I placed Crazy Glue into the holes (without anything in the holes) and let it dry. This hardens and strengthens the holes to prevent cracking. Then I SUPER SLIGHTLY enlarged those 1/16" inch hole with a 5/64" bit. This makes the holes a super smidgen larger, and allows for a less squeeky-tight fit that can also crack the scales. Works perfectly!!

A quick note about linseed oil. ALWAYS open-up the wadded material you used to wipe it down with, and let it air dry in a non-folded position. Linseed oil does not dry like normal sealers. It uses chemicals that are mixed into the formula to generate heat to dry quicker. If left wadded-up, these solvent-soiled wads will actually self-combust and start a fire. (Google it)!!

Anyhoo...here is the finished scales with the linseed oil I used. Follow the directions to the "T"!!

Then I installed the blade, peened it securely, and made sure to do my magic to ensure the blade was centered in the scales.

Wa-Laaaa!

A restored and finished 1837ish Wade & Butcher that looks "Mah-velous".

As a side note, I was having some issues getting a good edge on this "kinda smiling" blade, so I sent it to Dr Matt to get it honed.

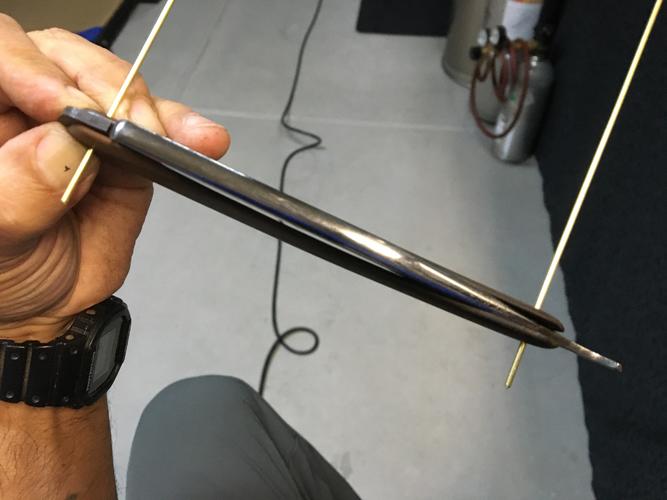

He did a KILLER job with the blade. Look at the very edge of the blade. That edge is so shiny and evenly honed, that it is acting like a mirror and reflecting the bricks in the fire pit. Sha-weet!

Anyhoo...that's my story, and I'm sticking to it.

Oh yeah...by the way. What an exceptionally smooth shaver.

It is a near wedge, if not a full wedge, and feels absolutely incredible.

Till next time.

Toodle-Loo!Last edited by RaymondMillbrae; 11-29-2020 at 09:30 PM.

-

The Following 5 Users Say Thank You to RaymondMillbrae For This Useful Post:

BobH (11-29-2020), JBHoren (11-29-2020), markbignosekelly (11-29-2020), planeden (11-29-2020), RussellR5555 (11-29-2020)

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote