Results 1 to 10 of 15

Thread: G Willis Hinchcliffe

Hybrid View

-

05-27-2021, 09:18 PM #1

G Willis Hinchcliffe

G Willis Hinchcliffe

Today i finished this G Willis Hinchcliffe Sheffield 1804-1850. In Ivory.

The reason i chose this one was because of the cracked scales at the pivot end. It gave me a chance to practice a vintage style repair. Basically lining just the pivot area and fixing the steel liners with pins. This type of repair appeals to me.

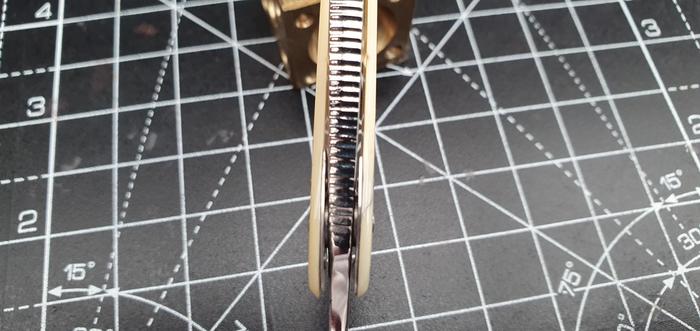

The blade was given a mirror polish finished with a whitening colour. Shame about the pitting near the tang stamp.

Honing was 10/20 laps: DMT 235

20 laps: Kramer Zwilling 400 Grit

Bevel set Kramer Zwilling 1K

Ozuku Kiita / Botan / Tenjou / Mejiro / Koma / Hard Tomo

50 Laps Linen / 50 Laps Shell Cordovan (To be specific)

This style of blade is susceptible to bad bevel angles . I went with one layer of Polyimide tape.

I took too many photos so this is a bit of a mishmash

-

05-27-2021, 09:43 PM #2

I think this beauty deserves to be in a shaving video

- Mick.

- Mick.

-

05-27-2021, 09:52 PM #3

Love that blade shape, I’ve tried grinding a couple of them so far with no luck. Nice job on the scales. Looks like it won’t ever crack there again given how you isolated it. Is that a pretty typical repair approach for the age of the razor?

One last question, is the spine evenly tapered from toe to tail?

-

05-27-2021, 11:02 PM #4Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Amazing work. It's beautiful.

Are the three pins a style choice, or is epoxy or CA glue not resilient enough for a long term fix?If you're wondering I'm probably being sarcastic.

-

05-28-2021, 08:21 AM #5

-

The Following User Says Thank You to JOB15 For This Useful Post:

planeden (05-28-2021)

-

05-28-2021, 12:50 PM #6Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,454

Thanked: 4830

Nice job. It’s nice to see old ivory kept going.

When JFK was talking about grinding that style, I am thinking he was try to make a razor that shape from scratch.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

jfk742 (05-29-2021)

-

05-28-2021, 08:14 AM #7

Last edited by JOB15; 05-28-2021 at 08:24 AM.

-

05-28-2021, 08:07 AM #8

30Likes

30Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote