Results 1 to 10 of 10

Thread: Custom Spike point: Part II

Threaded View

-

01-05-2010, 05:15 AM #1

Custom Spike point: Part II

Custom Spike point: Part II

Hi guys, I wanted to update you on my custom razor projects (here is the previous thread if you are joining now -- custom part 1). Today I heat treated my blades and it worked!!! I heat treated my three blades in the coal forge I built this week out of a brake drum from a big truck.

Here is a pic of my forge... nothing fancy, I used a shop vac for my blower and it worked very well. (here the fire is actually out, I was so excited while heating the razors that I forgot to get out my camera).

After heating up the steel to critical temp (checking both via steel color and magnetic tests) I immediately quenched the razors in peanut oil heated to about 150 F. Here is a pic of my crude set up.

After letting the blades cool to the touch in the oil, I tested the hardness with a fresh file. The file just slid right off of the steel with nary a scratch! WoooHooo! Now, I may have gotten lucky today with my heat treats, but it worked three times in a row, so I am pretty happy.

Next, my razors went onto a cooling rack on top of a baking sheet (in order to raise them up off of the sheet) and into a 400 degree oven for 2 hours in order to temper the steel.

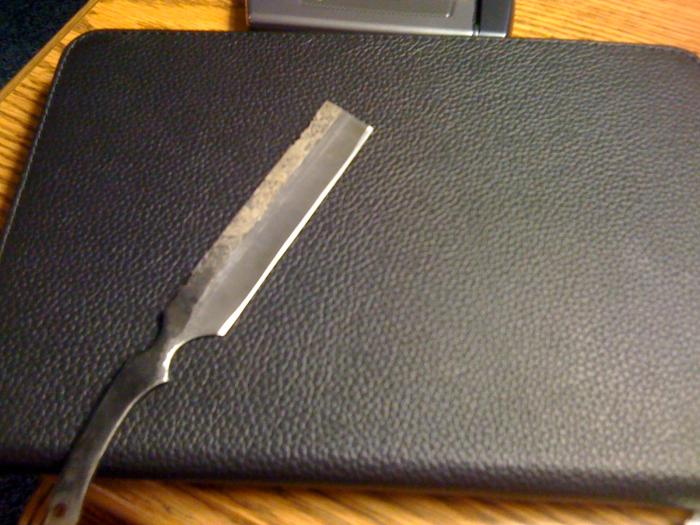

After the tempering, I summoned my courage and headed back to the grinder to finish the grinding... (I really was nervous, remember I had never hollow ground before and I really didn't want to ruin everything). I slowly finished grinding the razor, using a fresh belt and constantly cooling the blade in a cup of ice water. When I realized that I was actually done, and the blade hadn't been ruined by grinder heat, I was so excited that I couldn't help but put a test bevel on the blade. Here is what I have now:

As you can see, there are some uneven spots from my poor grinding, but all in all I am a happy camper. This edge is popping hairs off my arm at 1k... I can't wait to get this finished up and give it a test shave.

Today I only had time to get to the spike, but I'll be doing the final grinds to the other two this week, so wish me Luck!

All comments are welcome, thanks for looking

DaveLast edited by Del1r1um; 01-05-2010 at 05:21 AM.

-

The Following User Says Thank You to Del1r1um For This Useful Post:

FTG (01-12-2010)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote