Results 1 to 10 of 13

-

04-29-2011, 02:36 AM #1

Prince Royal with custom scales (pic heavy)

Prince Royal with custom scales (pic heavy)

This is my first attempt at scales and blade polishing!

Blade: hand sanded from 150-1500g paper; dremel polished with Dico as in the tutorial.

- round point, approximately 6/8, bellied hollow (I think), top and bottom jimping

Scales/wedge: purple heart; dremel + hand sanded with 220g paper; 3 coats of Formby's tung oil, hand gouged fish scale pattern

Pins and washer: plain brass

Tools: Dremel for blade polish and major scale shaping, cheap gouge from Michael's, coping saw, assortment of small files, cordless drill with 1/16 bit, and my mitts.

After disassemble, before cleaning:

Casualty of rusted pins and hamfistedness (oh well, they were warped anyway)

Carefully taped to help preserve the gold

After hand sanding progression

After dremel compound progression

Last edited by TwistedOak; 04-29-2011 at 04:41 AM.

-

04-29-2011, 02:45 AM #2

Good job on the blade, The goldwash has to go sometimes! Lets get it into some scales!

"Don't be stubborn. You are missing out."

I rest my case.

-

04-29-2011, 02:50 AM #3

Scale creation

Scale creation

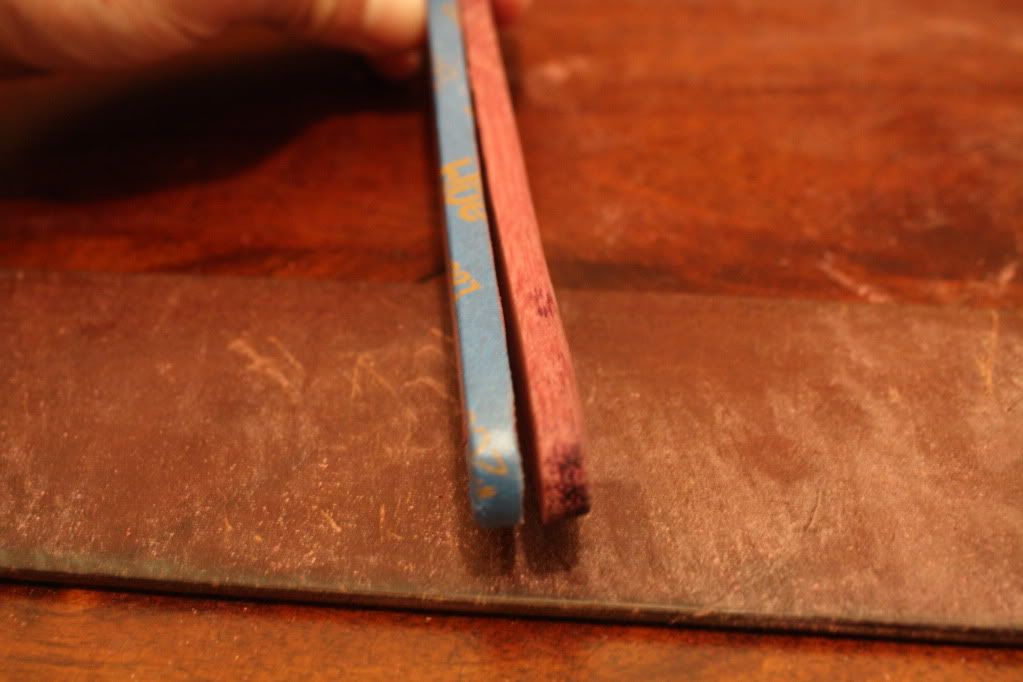

Rough shaping from a 1"x1"x6" block of purpleheart:

Drilled holes before cutting in two. A drill press would have made this less stressful. However, if you aren't perfectly straight you can sand down the scales from the outside (leaving the two sections of the drill path closest to each other). This will lessen the delineation of your crooked pin hole.

I found that measuring and marking a bisecting line, then taping along it made a straight cut by hand easier with a coping saw.

Of course changing the angle helped make quick work of cutting, but left a bit of smoothing work to be done.

-

04-29-2011, 02:56 AM #4

and the finished product :D

and the finished product :D

These handles are a big ol' fat set and you can feel the difference between your ring and middle finger when holding it. Whether that's a bad or good thing is up for review...

-

04-29-2011, 02:57 AM #5

little side lighting to show relief:

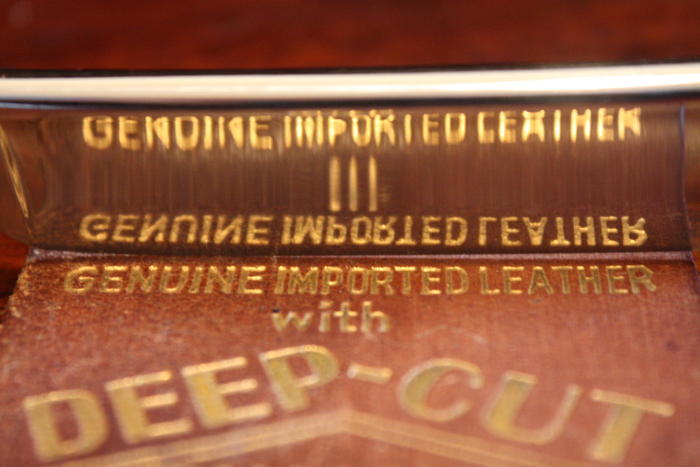

I still haven't found out who's stamp this is:

-

04-29-2011, 03:41 AM #6

-

05-01-2011, 04:30 PM #7

Can anyone help me identify this blade? I have had no definite answers to who made it.

-

05-01-2011, 06:29 PM #8

Very nice work. I'd love to shave with it and see how those wide scales feel. Great job.

-

05-01-2011, 06:36 PM #9

I have already been thinking of taking it apart and making some modifications to them...

sanding them down to be a normal or even thinner width than normal scales, lining them with some gold/brass, and slimming down the wedge. But I have another scales project that needs to get finished before I attempt to redo these.

-

05-02-2011, 02:38 AM #10

Really nice job on the blade & carving.

First attempts always have some challenges for us

It may be the pics but your wedge looks reverse tapered & too thick which is maybe why you needed to hollow out the scales near the pivot to clear the tang ? Thinner scales will also allow the flex needed for a good fit .The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

TwistedOak (05-02-2011)

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote