Results 1 to 5 of 5

-

02-24-2013, 05:34 AM #1

From gift to restoration in an evening

From gift to restoration in an evening

My wife went with her mom & the kids to a local antique store today. I had to work today but she decided to bring me a little present. It's a 5/8 Joseph Haywood & Company spike point. By the shape of the tail, I'd say it dates back to about the mid-nineteenth century. The only issue with it was that the scales were cracked clean through. So, what did I decide to do about it? Well... this.

Before:

After:

I decided to keep the patina intact and simply rescale the blade. The new scales are made from African Rosewood. I even salvaged the original wedge (yes, I know it's lead. I was careful). So, in the span of an evening, I took an antique store relic that had seen better days and gave it another hundred years or so. More photos can be found here.

-

02-24-2013, 07:09 AM #2

nice gift and restore !!

like the look those scales give it and it looks like a good shaver !!

-

02-25-2013, 01:54 AM #3

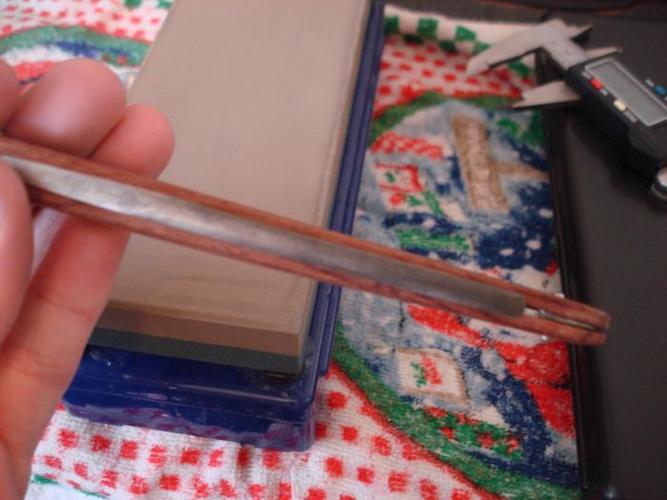

Thanks guys. While I'm happy with how it looks, honing it is completely confounding me. The spine is angled from 4.65 mm at the toe to 5.72 mm at the heel. The blade measures 16.00 mm at the toe and 17.12 mm at the heel. If my limited experience has taught me anything, it's to know when to say "stop". I've tried with one layer of tape and I've tried honing without it. All I've managed to do is create a blade that is somehow duller than when I first started. I'm not sure if I should regroup and try again or throw in the towel and have a pro do it. Here are some shots of what I've got to work with.

As you can see, there is some significant warping of the blade as well as uneven hone wear. Just setting the bevel on this guy is giving me fits. At this point, I've stopped trying to hone it until I can get some advice on it (or I may just have to send it out to a pro).

-

02-25-2013, 02:38 AM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Nice blade,send it to a pro.it has issues that only a pro can fix I fear

-

02-25-2013, 03:10 AM #5Bladesmith by Knight

- Join Date

- Jun 2007

- Location

- Murrumba Downs, Queensland, Australia.

- Posts

- 571

Thanked: 203

What a woman!! Oh - and good work on the razor too.

Yeah - i'd go pro on sharpening. You have done such a great job, she deserves a perfect edge.

Regards,

Adam

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote