Results 11 to 17 of 17

Thread: Black Devil (Mertens&Heider)

-

06-03-2013, 10:32 AM #11

@TwistedOak: yes scales are a bit too thick aren't they... was not sure about that, but since i don't have a belt sander I was a bit afraid I might damage them, plus since the finish isn't totally equal (thickness-wise) I am afraid that scales might curve unevenly if too thin.. maybe I'll give it a try when I get new torx fasteners... (ps. wedge is not glued in)

cudarunner: I've been looking through this post, and links and the most informative was this one Nuts and Bolts and Washers oh my From Microfasteners..., but as said before, the links from the post are outdated, and I can't seem to find the right fasteners and "tubes"

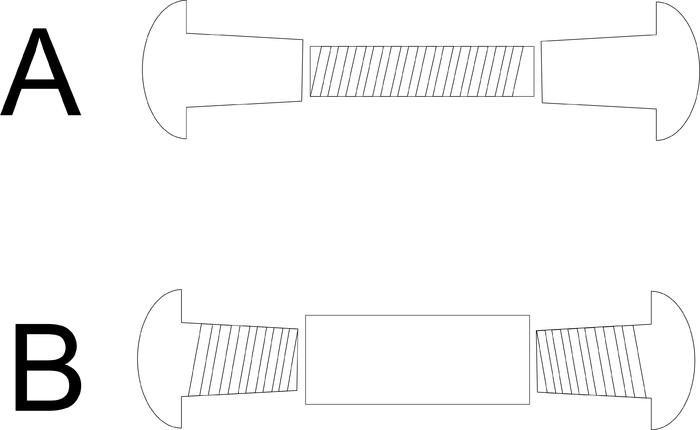

so to make my question a bit clearer I made this scheme,.. so 2 systems,.. :

A: the screw axle goes into the eg torx closed caps

B: the axle is a tube with thread and 2 eg torx screws go inside the "tube"

If system B is the case, can you get the "axel tube" that is 2mm wide (it should fit within the pivot hole in the blade)

-

06-03-2013, 09:43 PM #12

Wow, great restore. It looks fantastic. I like the shape of the scales and the finish too. Well done.

Stu

-

06-03-2013, 09:48 PM #13

let me refine my questions

.. (hope this is not too off topic yet)

.. (hope this is not too off topic yet)

if I understand correctly the "system B" from my previous post is the one usually used when screws are used on razors? when I managed to convert US to metric dimensions these were the smallest screws SBXS0202 - 2-56 X 1/8 - Button Head Screw - 6 Lobe Drive - Stainless - Micro Fasteners ? .. they are 2,2 mm in diameter, meaning that the "pivot tube" is thicker?

my question would be : is there any way of doing this without having to drill the blade (getting the pivot of app 2mm in diameter, and eg still use torx rounded screws (system B) or torx rounded caps, as I draw in previous post (system A kind of)?

I know it has been written in previous threads before but I somehow can't seem to get it... sorry

ps. this screws above have a 5 star hole and not the 6 star (torx - Torx - Wikipedia, the free encyclopedia)?

edit: @Str8Raz0r: thanksLast edited by miha; 06-03-2013 at 09:51 PM.

-

06-06-2013, 06:41 PM #14

Looks good, Interesting scales design.

-

06-06-2013, 07:18 PM #15

@kalerolf: thanks,.. amd trying to work through the screws problem but it doesn't seem to go anywhere

... just now I recieved some info that is going to get the things going

... just now I recieved some info that is going to get the things going

-

06-10-2013, 10:14 PM #16

If you lay some sandpaper on a flat surface (doesn't have to be hone surface flat) and as long as you distribute the pressure somewhat evenly along the scale I bet you could get it down to a better width without interrupting the flexibility at the thinner spots.

-

06-11-2013, 06:25 AM #17

maybe I'll give it a go when I'll get the screws, thanks

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote