Results 11 to 20 of 29

Threaded View

-

07-02-2013, 01:43 PM #1Senior Member

- Join Date

- Jun 2013

- Posts

- 120

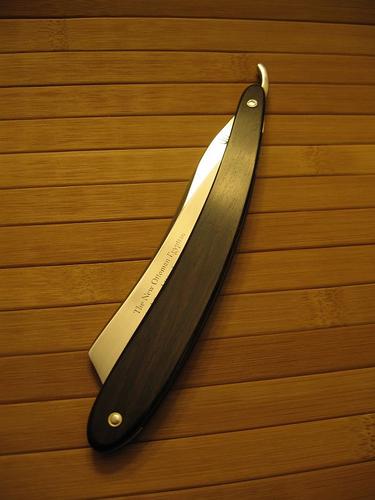

Thanked: 272 The New Ottoman Egyptain And Royal Windsor Razor

The New Ottoman Egyptain And Royal Windsor Razor

Hello,

i would like to show you a Razor that i made long time ago. It was the first folding razor i ever made for a customer.

It is a replica of the "Ottoman Egyptain And Royal Windsor Razor" from Wade and Butcher. My customer always wanted to own this razor but didnt manage to get one, so he ordered the replica from me.

The blade is made of a special steel, with 1,5% carbon 0,2%Tantal and traces of Silver. I alloyed and casted this steel specifically for this razor.

The handle is made of Grenadill. All other parts like the pins and the wedge are 925/000 silver.

I hope you like it.

kind regards,

Ulrik

-

75Likes

75Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote